Sharpening Services

They make bits and blades cut like new, but are they worth the cost?

Synopsis: Sharp edges are essential for hand and power tool work. Hand tools are usually easy to sharpen right in your shop, but motor-powered cutting tools are a different story. Tablesaw blades, dado blades, jointer knives, planer knives, and router bits are best sharpened by a professional. In this article, Tom Begnal takes a closer look at sharpening services. He tells you what to look for in a good service and analyzes the dollars and cents of resharpening versus replacing a variety of blades and bits.

Woodworkers use all sorts of cutting tools, some powered by hand, others by electric motors. Either way, it’s important that every edge is sharp. Otherwise, the tools don’t work as designed.

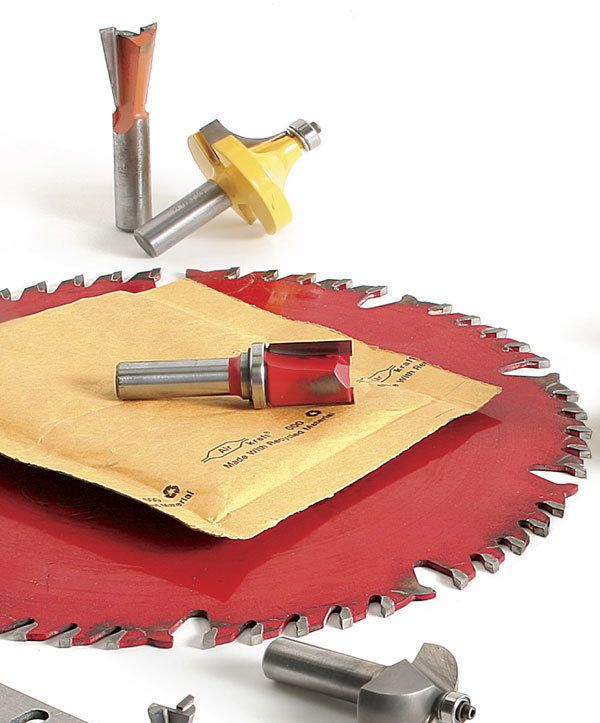

Typical hand tools, like chisels and plane blades, sharpen relatively easily in minutes, right in the shop. But motor-powered cutting tools are a different story. Tablesaw blades, dado blades, jointer knives, planer knives, and router bits are best sharpened by a professional. A good one will have the sophisticated equipment needed to sharpen these very long, complex, or multiple edges, many of them hard tungsten carbide. Most will ship the tool back to you within two to four days after it shows up in their shop.

Sharpening changes the size of a tool

Be aware that the size of a cutting tool changes slightly after sharpening. The diameter of a sawblade or dado cutter becomes slightly smaller. So, too, does the diameter of a straight router bit. The cutting radius of a roundover bit gets bigger, while the radius of a cove bit gets smaller. Planer and jointer blades end up narrower.

Whether or not a smaller tool is an issue depends on the tool itself and, to some extent, on how you plan to use it. It won’t really make a difference when the diameter of a sawblade measures a few thousandths of an inch smaller after sharpening. A larger radius usually won’t be an issue either, unless it’s a matched set of router bits for cutting a rule joint on a drop-leaf table. When installed, planer and jointer knives can be adjusted to account for any change in width.

But if a bit is bearing-guided, and the bearing is intended to create a flush cut, the cut might not be flush after a sharpening. The result may be a slight step along the routed edge. Matched rail-and-stile bits (also called cope-and-stick bits) are designed to make mirror-image cuts that fit together perfectly. Most users find that the bits can accept at least one sharpening before the fit becomes less than perfect. Check with your sharpener before sending along a set of these bits. Other types of cutters usually can be resharpened several times. Sawblades and bits that come with relatively large carbide tips typically get you a few more sharpenings than blades with smaller tips, something to consider when buying.

From Fine Woodworking #195

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Rockler Silicone Sharpening Stone Tray

Norton Water Stones

Log in or create an account to post a comment.

Sign up Log in