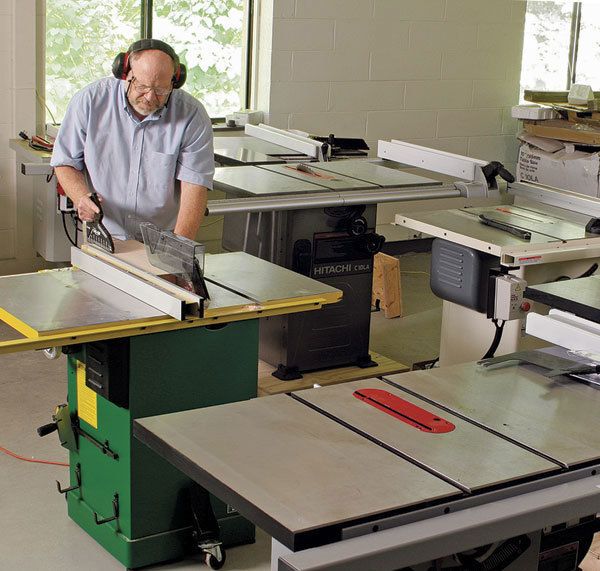

Tool Test: Hybrid Table Saws

Do serious woodworking without springing for a cabinet saw

Synopsis: Until relatively recently, a home woodworker looking to buy a floor-standing tablesaw had just two choices—a contractor’s saw or a cabinet saw. Now there’s a third choice, commonly called a hybrid saw, that fits between the two in price and performance. Tom Begnal reviews 10 hybrids to see how they stack up: Craftsman 22124, Delta 36-717, DeWalt DW746X, General 50-220C M1, Grizzly GO478, Hitachi C10LA, Jet JWSS-10CSPF, Shop Fox W1748, Steel City 35601, and Woodtek 148-271.

Until relatively recently, a home woodworker looking to buy a floor-standing tablesaw had just two choices—a contractor’s saw or a cabinet saw. Now there’s a third choice, commonly called a hybrid saw, that fits between the two in price and performance.

When it comes to power, hybrids generally have between 13⁄4 hp and 2 hp. Cabinet saws begin at 3 hp. But if you work with very thick stock only occasionally, a 3-hp motor isn’t a must. A 13⁄4-hp to 2-hp motor will cut just fine through the thickest hard maple—you just have to cut a bit slower. Also, hybrid saws, like contractor’s saws, have 110v motors. That means there is no need for special wiring; you can plug them into any household grounded outlet. On the other hand, cabinet saws run on 220v.

Choosing a favorite

All these saws cut 3⁄4-in.-thick stock without strain. And, with the exception of the Hitachi, all could cut 23⁄4-in.-thick maple simply by slowing the feed rate. Also, all had good rip fences, a very important component in a tablesaw.

That said, the Woodtek had the most power, the widest rip capacity, a rollaround stand (that worked wonderfully), and a low price. I felt it was the best overall saw in the bunch. And, because it comes at a low price, it’s the best value, too.

15-point inspection

What makes a good tablesaw? When evaluating the overall quality of a tablesaw, I take into consideration a number of categories—15, to be exact. A saw that does well in all 15 areas is an excellent tool.

1 Miter slots

For smooth, safe cuts, the tablesaw blade must be parallel to the miter slots at any blade angle. I measured blade/miter-slot parallelism with a 10-in.-dia. testing plate at 0º and then took a reading to see how different the alignment was with the plate at 45°. A difference of more than 0.007 or 0.008 means you’ll have to shim the trunnions, a tedious process of trial and error on most saws. Anything less can be solved with a side-to-side shift, which is easier. It’s important to check your saw when it arrives. Any of them can be bumped out of whack during shipping.

From Fine Woodworking #195

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Makita LS1219L Miter Saw

Forrest Woodworker II Blade

JessEm Mite-R Excel II Miter Gauge

Log in or create an account to post a comment.

Sign up Log in