Use Screws Like a Pro

Get maximum holding power in every situation

Synopsis: No place for screws in woodworking? Don’t be so sure. There are many woodworking tasks where a screw is just the thing. The trick is to select the right screw for the job, and to understand how to get the most holding power from it. Robert Settich takes you through the ins and outs of using screws — from drilling the correct clearance and pilot holes, to dialing in a precise fit, to countersinking and counterboring. He explores the use of screws in solid-wood construction, plywood, and MDF.

Some purists will tell you there’s no place for screws in woodworking. If they mean that screws can’t replace a snug mortise-andtenon or a seamless dovetail joint … ok. But the fact is, screws do the job—and do it well—in many woodworking applications. The trick is to select the right screw for the job, and to understand how to get the most holding power from it.

The basics

Most crucial to a screw’s holding power is its resistance to being pulled out. The more thread surface in contact with the wood, the more resistance. So, to muscle up holding power, use a longer or thicker screw, one with a deeper thread pattern, or any combination of those properties.

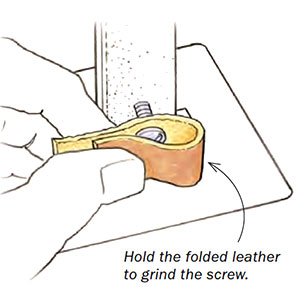

A thicker root (around which the threads are wound) also beefs up a screw’s torsional strength, or resistance to twisting forces that can snap it, usually after its head hits the wood. To avoid this, choose the right screw, drill the right-size pilot hole, and don’t overdrive. Set the power driver’s clutch to a lower setting or make the last few turns by hand. overdriving also spins the screw after it reaches full depth, reducing the wood fibers to a fluff and leaving the screw with no holding power.

Pilot holes—In woodworking, always drill pilot holes. without them, screws simply push the wood fibers aside. This is ok in carpentry, but with the harder woods and often thinner pieces used in making furniture, it’s a recipe for splitting. The general rule is to drill a pilot hole in the target piece that’s the size of the screw’s root. This is easy when using a rolledthread screw, in which the root diameter is consistent throughout the length of the screw, tapering only at the tip. For a cut-thread screw, in which the root diameter gradually tapers toward the tip, optimal drilling requires a tapered drill bit.

Clearance holes—Another critical element in a successful screw joint is the head of the screw. No matter how great a screw’s holding power, the joint won’t hold tight if the pieces being fastened are “jacked,” or not drawn tightly together. That’s where clearance holes come in. These are drilled through the top board (or piece to be fastened), allowing the head of the screw to pull that piece fast against the target board. To achieve this in most cases, the clearance hole should be as wide as the outer diameter of the screw’s widest threads.

From Fine Woodworking #195

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Starrett 12-in. combination square

Ridgid R4331 Planer

Jorgensen 6 inch Bar Clamp Set, 4 Pack

Log in or create an account to post a comment.

Sign up Log in