No-Clamp Veneering with Yellow Glue

I was making an end table and wanted to use a nice piece of walnut veneer on the top. Unfortunately, the substrate was too big to use a sandwich-and-clamp method, and I did not want to buy a veneer press for one job. A friend, Neil Artman, told me about a method that doesn’t require clamps or a press.

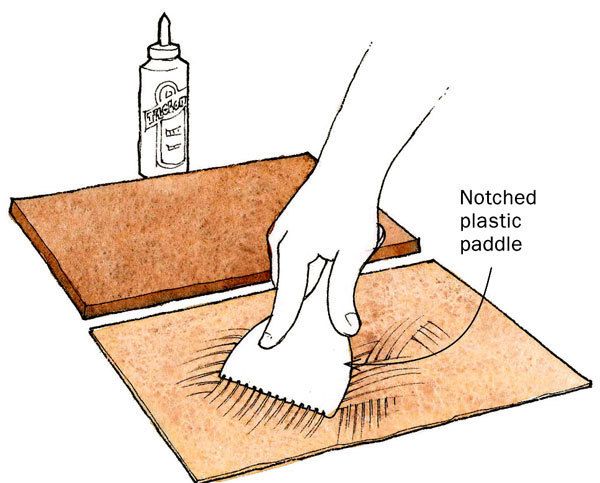

First, I bought a plastic paddle, the kind used to spread drywall mud, and cut kerfs into it about 1/8 in. deep and 1/4 in. apart. I then sprayed the show side of the veneer with water. I flipped it over and used the paddle to spread a liberal, even amount of Titebond Original Wood Glue on the other side of the veneer, being sure to cover the edges. As the glue soaked in, the veneer started to flatten out. Next, I spread an even layer of glue on the substrate with my altered paddle.

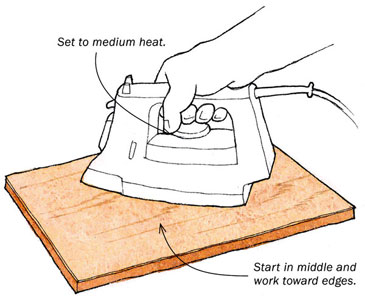

At this point, I let both the glue on the substrate and the veneer dry separately for at least an hour. Once the glue dried, I carefully placed the veneer (glue side down) on the glue side of the substrate. Once I had it in position, I used an iron set to medium heat to reactivate the glue and adhere the veneer to the substrate.

I started in the middle and worked toward the edges to cover the entire veneer. I first tried this on a sample piece and was shocked at how well it worked.

Editor’s note: Although the process worked well with Titebond Original, a customer-service representative at Titebond says Titebond II will work better because it tends to have better grab and provides more strength in the wet form.

Drawings by Jim Richey.

Drawing by Jim Richey.

Fine Woodworking Recommended Products

Whiteside 9500 Solid Brass Router Inlay Router Bit Set

Bahco 6-Inch Card Scraper

Comments

Excellent tip! How could I utilize this method to build starbursts and other complicated inset designs?

Thanks!

@RobertMorris348 you should tape up and join all the pieces of veneer first, to work it as one 'piece' essentially.

I tried this, using Titebond Cold press veneer glue on my MDF kitchen island, which was already installed. In general, it worked, although I have a few warnings for anyone who wants to try this. Definitely don't wait too long after applying the glue or else the glue will become overly dry and won't remelt with the iron. I had to wait overnight the first time and that really did not work. Another bit of advice is definitely use a scraper of some kind to apply the glue - do not use a paint roller to apply the glue across the veneer surface! I think the paint roller applied the glue too thinly and too evenly which made the process harder. I also might not have used enough glue the first time - Don't be too shy with this veneer glue. It's quite thin. I still had to use the paint roller to apply the glue to the MDF side, because that was already in place and vertical. But I used a scraper on the veneer and that worked so much better the second time.

I couldn't get my hands on a veneer saw, so I found that cutting the veneer worked best when I used a really sharp Olfa art knife, like a fancy exacto knife with a really sharp blade, and I taped the line where I was going to cut with brand name painters tape, and I used a heavy board with sandpaper taped to the bottom to make the line and also hold everything in place during the cut. Things went badly when I skipped the painter's tape. Moving my non-dominant hand along the board to anchor really thoroughly where the cut was being made was also important.

Good luck!

Log in or create an account to post a comment.

Sign up Log in