Q:

Whenever I run a board through my thickness planer, it winds up with snipe at one or both ends. The infeed and outfeed tables are level with the planer bed. What can I do?

Jim Ashton, St. Paul, MN

A:

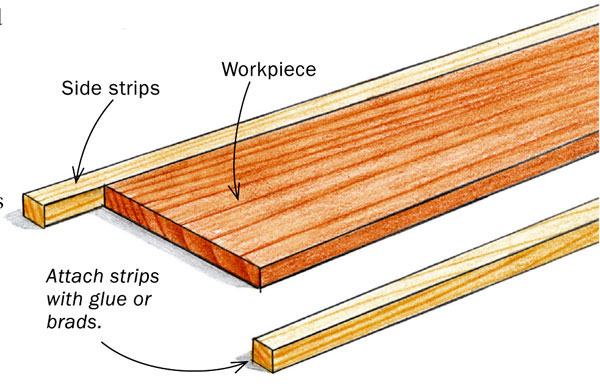

The simple solution is to size your workpieces long and then cut off the snipe. Or, you can run strips of wood along the sides of the board being planed. Make the strips at least 1 in. wide and the same thickness as the workpiece. To determine the strips’ minimum length, measure the distance between the planer’s cutterhead and either of its drive rollers (with the machine unplugged). Add 1 in., multiply by 2, and add that number to the length of your workpiece.

Cut the strips and attach them, centered, to the workpiece sides with glue or brads. If you use brads, make sure they’re far enough below the surface to avoid damaging the planer knives.

Add strips of wood to avoid snipe: One way to avoid snipe is with side strips. Make them the same thickness as the board being planed, but extending beyond both ends. If there’s snipe, the strips take it.

|

|

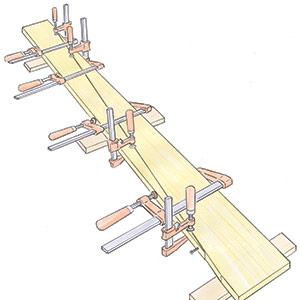

During planing, the strips reach the cutterhead first, sustaining any snipe, and are held flat under the outfeed roller by the time the workpiece reaches the knives. This virtually eliminates the unsupported lift that causes lead-end snipe. Then, as the board exits, the strips’ tail ends are secured by the infeed rollers, keeping the back of the workpiece from tipping up into the cutterhead.

If your board and side strips are less than 1/4 in. thick, they could flex and still leave the board with snipe.

Drawing: John Tetreault

Fine Woodworking Recommended Products

Starrett 12-in. combination square

Incra Miter 1000HD

Comments

I've done both, and both work well. The strips are obviously a good bit more work, especially with multiple workpieces to plane. But if you're tight on material they can be a big help.

Log in or create an account to post a comment.

Sign up Log in