Tool Test: Forstner Bits

For unmatched quality and precision in your drilling, you can't beat these bits. We look at 18 brands to see which are best

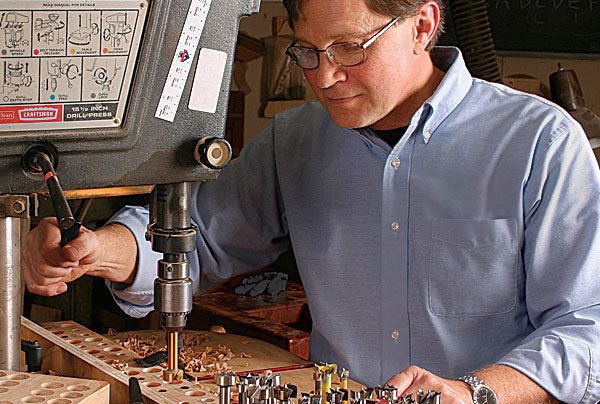

Synopsis: No other type of drill bit can match the clean rim and sides produced by a Forstner bit. That makes it essential for woodworking: it’s simply the best tool for drilling flat-bottomed holes that are sized and located accurately. Contributing editor Roland Johnson tested 18 brands of Forstner bits, and concluded that although the design and performance of different bits varies widely, you don’t have to break the bank to get an excellent set. This article covers the nine bits Johnson found to be the best performers. Results for the tests on the other nine are covered in an online-only supplement.

Brands of steel bits covered in the print article include Bosch, Famag, Fisch, Freud, Grizzly, Porter-Cable, and Woodcraft. Brands of carbide bits include Freud and MLCS.

Few woodworking tasks are as frustrating as trying to bore the perfect hole—accurately sized, accurately located, and with a cleanly cut rim. Standard woodworking twist bits, originally designed to cut metal, often leave ragged, inaccurate rims, are difficult to place accurately, and can wander off course resulting in uneven holes. Brad-point bits are better, creating accurate, clean holes, but they don’t make it easy to bore overlapping holes or enter the wood at a sharp angle.

The best design for boring high-quality holes is a Forstner bit. Since it was patented by Benjamin Forstner in 1874, this bit has been helping woodworkers cut clean holes with precision (see photos, facing page). Today, Forstner bits come in a variety of designs. To find out which ones are best, I tested 18 brands. The top nine bits are listed on the following pages; the rest are shown on FineWoodworking.com.

How the Forstner bit has changed over the years

The original Forstner bit did not have a center spur and was guided solely by the rim. The design left a clean-sided, flat-bottomed hole, but the bit was hard to position. Most of today’s Forstner bits have a center spur and a partial rim. The center spur positions the bit precisely on the workpiece but leaves a small dimple in the center of the hole. In a stand-alone hole, the spur makes the initial contact with the wood, but in other cases the rim alone can be in contact with the wood, guiding the bit.

Testing for accuracy, design, and endurance

I tested 1⁄2-in.-dia. and 1-in.-dia. bits. The former represent typical smaller bits used for drilling mortises and pocket holes, while the latter allowed us to test the toothed rims that most manufacturers use for larger bits.

I measured the diameter of each bit to see how close it was to the specified size, and then I measured the diameter of the hole itself. Most of the holes were less than 0.005 in. larger than their respective bit, an acceptable amount.

The next series of tests was to see how the 1⁄2-in. bit cut overlapping holes and holes drilled at an angle. As I mentioned already, bits with the largest rim did best at this test, while those with little or no rim and only outside spurs were at a disadvantage.

From Fine Woodworking #197

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Shop Fox W1826

Grizzly G0495X Industrial Helical Cutterhead 8-in. Jointer

Rikon 10-3061 10-in. Deluxe Bandsaw

The saw has two speeds: 3,280 sfpm (surface feet per minute) for wood and 1,515 sfpm for soft metals and some plastics.

Log in or create an account to post a comment.

Sign up Log in