Out of the Past and into the Present

Learn tips on reproducing period furniture using books, a trip to see the original, and a full-size plan

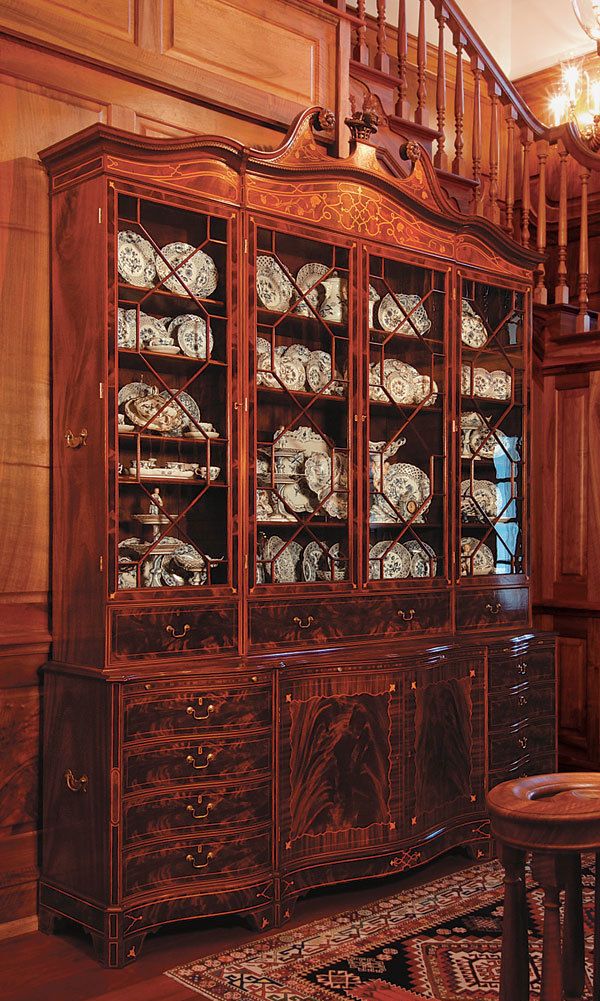

Reproducing museum furniture isn’t easy, but a combination of tricks can bring you extremely close to the original. According to Jeff Williams of Irion Company Furniture Makers, who made the Holmes-Edwards library bookcase (right) featured on the back cover of Fine Woodworking #198, the best-case scenario is to have the original in your shop as you are making the copy. He couldn’t do that, but he did the next best thing. Williams began with photos and documentation from a book, then visited the original in the Heyward-Washington House in Charleston, S.C.

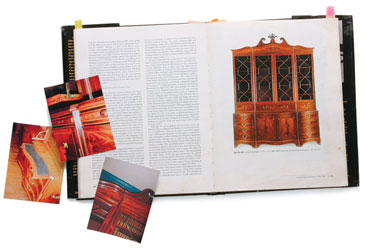

The Furniture of Charleston 1680-1820, Volume I: Colonial Furniture by Bradford L. Rauschenberg and John Bivins Jr. was a tremendous resource for Williams. From it he got dimensions, a list of materials, construction methods (including photos of joinery), and details of the pediment, marquetry, and inlay, which he enlarged on a photocopier to use as patterns. Most importantly, he was able to familiarize himself with the overall piece, making his visit to the original as productive as it could be.

The rare, full access he had to the original was also invaluable. He got detailed measurements, tracings of shapes, and photographs not shown in the book. When he returned to his shop, Williams began converting all this information into full-size plans before cutting a single piece of wood.

Here are Williams’ steps to creating a reproduction:

1. Start at the source

Williams gathered information from books, photographs, and the original piece.

2. Make a full-size plan

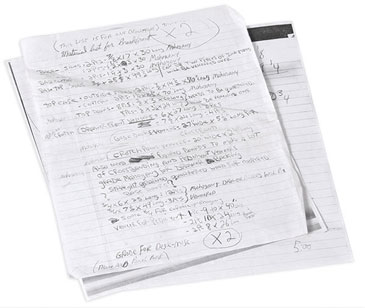

Before compiling an extensive materials/cutlist (above), Williams turned the information he’d gathered into a full-size story board for the height of the piece (without the pediment) and its vertical landmark points.

He then made a full-size drawing of half the width and full depth, marking all the vital measurements and connecting the dots (above).

3. Add the details

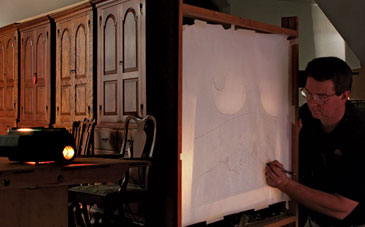

Creating the pediment. Williams projected a slide through a glass panel, adjusting the distance to get to full size. Drawing on paper taped to the far side kept his body from blocking the projection as he traced.

Sizing the marquetry. He used a circular proportional scale to calculate how much to enlarge an image on a photocopier, checking the size against the drawing of the pediment.

Making templates. Williams transformed his measurements and tracings into rigid templates for the 10 different curves on the drawers, pediment, doors, feet, and plinth.

For more on the Irion Company’s nine-year commission and the 90-plus reproductions it has entailed so far, see Greatest Commission Ever?

From Fine Woodworking #198

Fine Woodworking Recommended Products

Festool DF 500 Q-Set Domino Joiner

Bessey EKH Trigger Clamps

Estwing Dead-Blow Mallet

Log in or create an account to post a comment.

Sign up Log in