The Ultimate Shop Plywood

Build better jigs, tables, cauls, and cabinets with phenolic plywood

Synopsis: Phenolic-surfaced plywood is simply Baltic-birch plywood with a thin layer of phenolic resin in both faces. But that little layer of resin makes all the difference in the world. This specialty material is ideal for woodworking shops because it is strong, flat, and durable, and its glossy surface is perfect for jigs, cauls, fences, cabinets, and other uses. Any place where you need to run workpieces across a surface is the perfect place for phenolic. Stuart Lipp offers advice on finding, purchasing, and using phenolic plywood to make life easier in your shop.

On my first day working in the pattern shop at Steinway & Sons, I was introduced to a great material that has changed my woodworking. Phenolic-surfaced plywood is Balticbirch plywood that has a thin coating of phenolic resin on its faces. Used in electrical panels and switches because of its stability and strength at high temperatures, phenolic resin makes this plywood very resistant to moisture, heat, chemicals, and abrasion. Phenolic plywood also has superior strength, flatness, and durability compared to other types of plywood. Its nonstick, glassy surface makes it popular in the concrete industry, where it is used to make forms and molds.

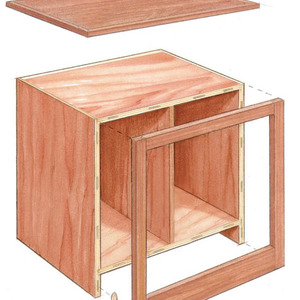

All of these qualities combine to make phenolic plywood ideal for many woodworking applications—from jigs, fences, and cauls to work surfaces and cabinets. Anywhere a jig or workpiece needs to slide over a surface or you don’t want glue to stick is the perfect place for phenolic plywood. It is manufactured in 4-ft. by 8-ft. sheets, in thicknesses of 1⁄2 in. (12.7 mm) or 3⁄4 in. (19 mm).

How to get phenolic

Phenolic plywood is a specialty material, so don’t expect to find it at your local home center. It has been around for a while, though, under such aliases as Colorfin, Park lex, Euro color Ply, Wisa, and Finnform. Color options are light brown, dark brown, red, black, green, yellow, white, or clear. However, suppliers tend to purchase one color in bulk and ordering specific colors can add to the price. Cost varies quite a bit from supplier to supplier, from $54 to $140 for a full sheet of 3⁄4-in. material. The difference depends on the inventory and colors the supplier stocks.

Woodcraft sells quarter-sheets of 1⁄2-in. and 3⁄4-in. phenolic. White Cap Construction Supply stocks it and has over 150 stores across the United States, but few in the Northeast.

Use for jigs, surfaces, and cauls

When it comes to improving machinery performance and jigs, phenolic plywood is at its best. The surface is so slick that other materials glide over it, making it perfect for all types of jigs and work surfaces. The top surface of a shopmade router table is a good place to use phenolic. So is a tablesaw outfeed table. Made of phenolic, it will perform better than a basic plywood table or a roller stand, and can double as a glue-up table. Dried glue pops right off.

From Fine Woodworking #198

For the full article, download the PDF below:

Fine Woodworking Recommended Products

WoodRiver Router Bit Storage Case

DeWalt 735X Planer

Ridgid R4331 Planer

Comments

I never see full sheets of this at any of the places I buy lumber or woodworking materials. I buy a Wilsonart 36 in. x 96 in. Laminate Sheet (web ordered from a big-box store) and glue it onto Baltic birch with contact cement. The laminate is about $40, so this is likely no worse off than buying it pre-affixed to the plywood. It has the advantage of allowing you to choose from a wide varieties of colors. I agree though, that it is great for jigs and worktops.

I love this stuff I made all my counter tops in my shop out of it. Dry glue and epoxy just pop right off. It is dead level flat with no voids. It is used for concrete form work so most contractor supply places carry it. Don’t go in and expect to buy one sheet from them.

“[Deleted]”

Do some suppliers call this stuff “Cabinet Liner” ?

Cabinet liner is a very thin and cheap liner that mimics plastic laminate. You apply it to the other side for dimensional stability. For example, you use an expensive laminate for the outside and edges of a cabinet door and then cabinet liner in the inside face.

I have never heard it called that.

This material is used by custom cabinet makers for shelving. It is my experience that they dispose of scraps large enough for jigs and fixtures. My local cabinet shop simply puts them in a box in the alley about once a week, free for the taking.

Won't melamine work just as well for most of these purposes?

Log in or create an account to post a comment.

Sign up Log in