Weekend Project: A Shaker-Inspired Wall Shelf

Sliding dovetails join the shelves to the curved, tapered sides. Building this piece will let you hone your skills with a bandsaw and router. Get step-by-step instructions and a free project plan.

DOWNLOAD THE FREE PROJECT PLAN

My wife, Colleen, occasionally asks me to build a piece of furniture for our home. I would love nothing more than to honor these requests, but there never seems to be time. But a hanging shelf is one project that I figured I could finish quickly.

I got the inspiration from a drawing of a peg-hung Shaker shelf in Ejner Handberg’s book, Shop Drawings of Shaker Furniture and Woodenware, Vol. II. The shelf sides in Handberg’s drawing are curved on top, but the bottom is straight. I added another curve at the bottom, experimenting with different curves until one satisfied my eye.

Handberg’s Shaker shelves hung from a wall-mounted peg rail. I don’t have a peg rail at home, so the first time I made this piece, I used brass keyhole hangers. In later versions, including the one shown here, I used simpler brass hangers mortised into the second shelf from the top. These are less expensive, are easier to install, and make hanging the shelf a snap.

Consistency is the key to this piece. If you start with flat stock of uniform thickness and length, the joinery follows smoothly. To ensure consistency, do all your milling at once (all the stock is 1/2 in. thick) and use a plywood pattern and flush-trimming router bit for making identical curved and tapered sides.

The Shakers housed the shelves in dadoes, rather than sliding dovetails, and you can do the same. It won’t be as strong, but if you’re worried about the shelves, you can toenail them from the bottom with finish nails or brads.

|

Wall Shelf, Step by Step |

|

|

Rout grooves in the sides Cut the sides to length but leave them at least 1/4 in. wider than the widest dimension, then mark the centerlines for each shelf on both pieces. Using a slotted piece of plywood to guide a 1/2-in. router template insert, cut the dovetail slots. Rough the slots with a 1/4-in. straight bit, then finish with a 3/8-in. dovetail bit. |

|

Trace the pattern, bandsaw sides With the grooves routed, cut the curved and tapered sides. First make a plywood pattern matching the shape of the sides of the shelf, trace the pattern onto the back of each side, and bandsaw the shape close to the line. |

|

Make both sides identical After roughing out the sides, clamp each side into the plywood pattern. Then rout the edge with a 1/2-in. flush-trimming bit, either using a router table or a handheld router setup. This step will remove any tearout created when you routed the dovetail grooves, and it makes each side identical. |

|

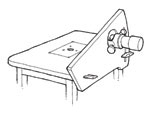

Rout dovetails on the shelves To cut the dovetails, mount the router horizontally on the router table (see below). This makes it easier to adjust the height of the cut. It also lets you hold the workpiece flat on the table. Adjust the depth and height of the router bit to match the depth of the slots. |

|

A horizontal dovetailing fixture Make a fence that holds the router and attaches to the edge of the router table. Mount the router horizontally in a recess in the fence, as shown. Handscrews fix the fence at the desired height. |

|

Cut shelves to width and assemble Cut the shelves to width after you cut the dovetails on the ends, so you can remove any tearout from the router. The front edge of the top three shelves is angled to match the tapered sides. Slide each shelf into the sides, starting at the bottom and clamping each shelf as you go. |

Excerpted From: Excerpted From:

Building Small Projects This book offers a wide variety of woodworking gems on a smaller scale: Projects to make in a weekend, mitered boxes, perfect frames for pictures and mirrors, compact wall-mounted shelves and cabinets, and much more. |

Log in or create an account to post a comment.

Sign up Log in