Q:

Two months ago, I laminated a U-shaped curve from approximately 40 strips of 1/16-in.-thick African mahogany using yellow glue. The finished piece has a 16-in. radius and 16-in. legs, and is 2-1/2 in. square in cross section. The problem is that the curve has tightened so that the ends of the legs are now more than 2 in. closer together. The lamination shows no sign of slippage. What happened?

Mark Laub, Minneapolis, MN

A:

The problem was caused by two related factors: too many laminations and the wrong glue. This combination introduced excessive moisture into the wood via the water-based yellow glue. As the water evaporated, it caused the wood to contract. Then the adhesive itself contracted as it continued to harden. To see this happen, leave a few ounces of yellow glue in an old cup and watch it pull away from the sides as it dries.

|

|

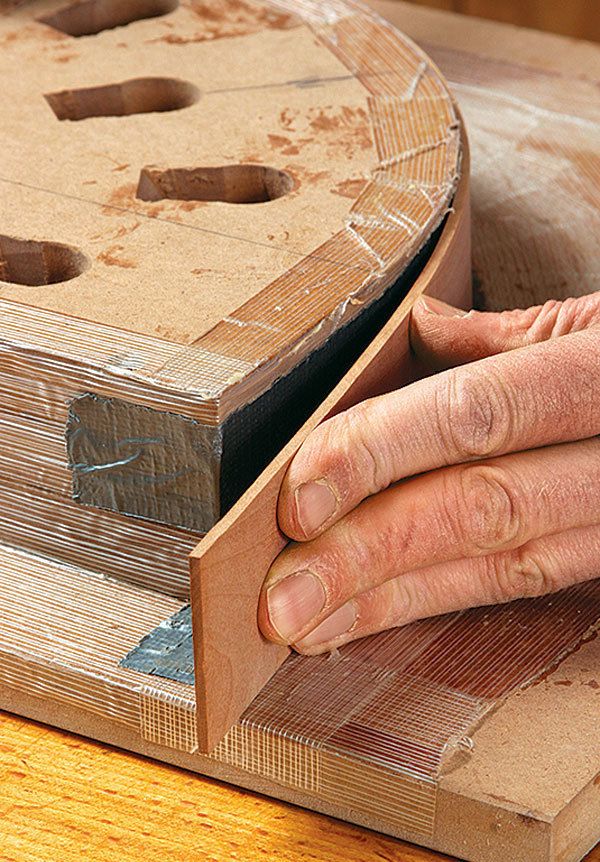

| Close-in. If a water-based glue introduces excessive moisture into the lamination, the wood can shrink as the glue cures, drawing the workpiece into a tighter curve. |

|

|

| Springback. The most common problem with laminations, it is caused by the strength of the individual plies overcoming the rigidity of the gluelines. |

It should take firm hand pressure to bend an individual lamination around the form. If the laminations are thin and too easily bent, then there may be too many and thus too much glue.

Alternatively, if the laminations are too thick, there will be a lot of stress along each glueline. Some springback will occur immediately when removed from the form, with continued movement caused by cold creep (the glue stretching). For your curve, I recommend about 26 laminations, each 3/32 in. thick.

A better adhesive than a water-based glue is Unibond 800 (www.vacupress.com), which is alcohol-based and eliminates the moisture shrinkage problem.

|

|

| Use the best glue for laminating. A two-part urea-formaldehyde glue will not introduce excessive moisture into a laminated part, reducing the chances of shrinkage as the glue cures. |

I apply it with a notched metal spreader made by Hyde, model No. 19120 (www.acehardwareoutlet.com). The very small-notches leave the perfect amount of adhesive for laminating or veneer work.

|

|

| Apply a thin, even coat of glue. Use a notched metal spreader to apply an even coat of glue to each ply. |

Finally, the clamping pressure has to be adequate and consistent. Otherwise, the uneven glueline will promote unpredictable movement.

Drawings: Kelly J. Dunton

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in