4 Custom Pulls That Please the Eye

Clever jigs create the curves and facets on these small parts

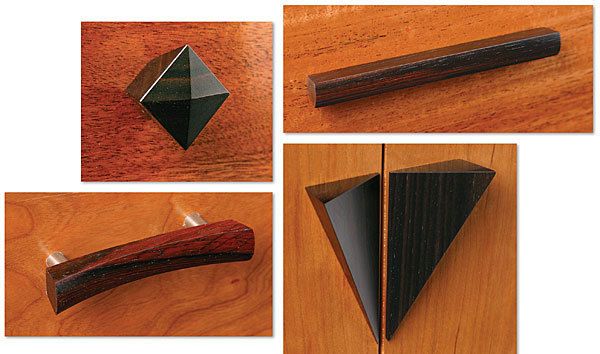

Synopsis: They may be small, but the pulls on doors and drawers are a crucial detail to consider when you’re designing a fine piece of furniture. Don’t limit yourself to off-the-shelf products. As Michael Fortune demonstrates, you can make attractive, functional custom pulls without a lathe, using simple but clever jigs on the bandsaw and tablesaw. Fortune provides expertise on making pulls that are comfortable, unobtrusive, and sized for easy use. His jigs make it easy to cut the curves and facets on these small parts easily, accurately, and safely. Shown are a simple square or diamond-shaped knob, a strong and slender drawer pull, mirror-image triangular pulls, and an elegant arched pull.

From Fine Woodworking #201

Door and drawer pulls are often the last detail we consider when building a piece of furniture. But a poorly chosen or placed pull can ruin a piece, while a well-designed, well-placed one can make the whole piece sing.

Don’t limit yourself to off-the-shelf pulls. Custom pulls aren’t difficult to make, and you don’t need a lathe to do it.

When we look at a piece, our eyes are drawn in different directions by the lines of its form. Custom pulls can encourage or discourage the eyes’ movement and so emphasize different aspects of the form.

That said, a pull’s function trumps its form. It should be comfortable, unobtrusive, and sized for easy use. And it should be removable, because finishing is easier without it. But don’t simply screw it on. Cut a tenon on the pull and fit it into a mortise. That keeps it from being split by the mounting screws, and from spinning loose later.

When making small knobs and pulls, I use jigs for accuracy and to keep fingers away from blades and bits. For the pulls, use a closed-grain hardwood. The ones in this article are ebony and rosewood.

Simple knob that sparkles: This knob can be mounted as either a diamond or a square. All four sides are tapered so that it’s easier to grasp, and the face is beveled to create four facets that meet in the center. A small tenon routed onto the bottom and fit into a mortise in the door prevents the knob from spinning and the mounting screw from splitting the knob. A diamond-mounted knob requires one more step than a square-mounted knob because its grain should run from corner to corner, rather than from side to side, so that no end grain is visible when the face is faceted.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Drafting Tools

Blackwing Pencils

Sketchup Class

Comments

In researching making pulls and knobs I found this great article by Michael Fortune. The article does not address what type of screw to use to secure the knob to the door/drawer. I am concerned about the screw (wood screw?) and knob separating over time. Would a brass threaded insert into the knob/pull, secured with epoxy, solve this problem? Other solutions? Should I be worried?

Log in or create an account to post a comment.

Sign up Log in