The Best Multipurpose Blade for the Bandsaw

Michael Fortune gives expert advice on choosing bandsaw blades.

Question:

If I start with only one blade for my bandsaw, what should it be? Down the road, what other blades should I buy?

—Dean Larson, St. Louis, MO

Answer:

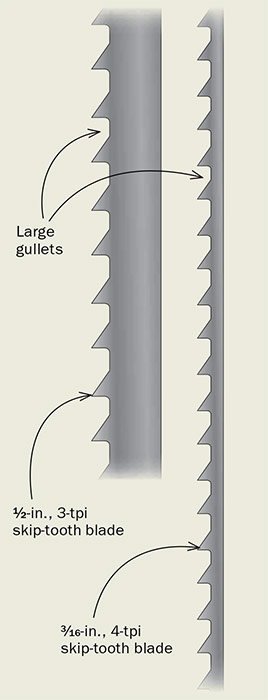

The best multipurpose blade for the making solid-wood furniture is a 1/2-in.-wide, 3-teeth-per-inch (tpi), skip-tooth blade made of carbon steel. As the name implies, every other tooth is skipped, or missing. This leaves a large gullet between the teeth, which allows for very efficient sawdust removal when cutting thick stock.

The same blade also can be used to saw thin stock. Just use a piece of scrapwood as an auxiliary table over the throat plate and cut a little slower.

You also can use this blade to cut a radius as small as 2-1/2 in., and even smaller if the back corners of the blade are rounded slightly with an old oilstone. This type of blade only costs about $8 and can be resharpened for about $3.50. I use BC Saw and Tool, where each order is custom made and the welds are uniformly excellent (www.bcsaw.com). A poor weld will compromise the performance of even the most expensive blade.

This first blade will cover 95% of your needs, but, for tight curves, I’d favor a 3/16-in.-wide, 4-tpi skip-tooth blade because it will cut a radius as small as 3/8 in.

From Fine Woodworking #201

Fine Woodworking Recommended Products

Rockler Dust Right 650 CFM

Stanley Powerlock 16-ft. tape measure

Rikon 10-3061 10-in. Deluxe Bandsaw

The saw has two speeds: 3,280 sfpm (surface feet per minute) for wood and 1,515 sfpm for soft metals and some plastics.

Comments

I'm a total beginner on bandsaws. The term "skip-tooth" has me confused a bit. Take the example of a 4-tpi skip-tooth blade. The tpi is completely unambiguous, I've got that. What is not clear is whether there is such a thing as a 4-tpi blade that is NOT "skip tooth"? Doesn't it just mean a low-tpi blade, and apply to all such blades? Thanks!

I'm surprised no one else has responded to this, but overall geometry of a "skip tooth" blade is different than a 4 TPI hook tooth or regular tooth blade. All three types of blades -- skip, hook and regular--can be found with 4 TPI, but the rake (angle the tip of the tooth meets the wood), the set (how every other tooth tip is splayed a little left or right of the blades spine) and the resulting shape of the gullets (spaces between the tips) are pretty different. It seems like a little bit of an exaggeration to say that a skip tooth blade has four smaller, stouter teeth per inch vs the larger closer spaced teeth per inch of a regular blade...but that sort of gets at the idea. Hook tooth blades are named, perhaps, a bit more true to their name as they have a lot of a aggressive rake and the gullets (the space between the teeth points) are "J" shaped. Skip tooth blades have a zero degree rake so their teeth meet the wood at a 90d angle and big, nearly squared-off, open gullets...this angle helps each tooth make a cleaner "chip-like" cutting action and the big, open gullets clear the waste better than on hook or regular toothed blades. Clearing the waste quickly is important when taking these big bites as the saw dust accumulating in the kerf generates a lot of friction...heat kills a blades sharpness like nothing else.

So, if a skip tooth blade is best for nearly all ww'ing, generally, why do the other two exist? In my experience, keeping regular tooth blade around is great for rough work -- general stuff where cut quality isn't an issue like making styrofoam models, cutting up framing lumber, etc. Hook tooth blades cut very fast and aggressively and are supposedly good for cutting plastics, non-ferrous metal, , or ripping thick soft woods? I can't verify, I've never owned one. Hope this helps.

MK

Many thanks! (I'd forgotten all about this question!)

Does anyone know of a new source for bandsaw blades? http://www.bcsaw.com doesn't seem to exist anymore.

Best all around blade is a Lenox 3/8 carbide. Expensive yes but lasts forever and leaves a great surface. Excellent product.

Log in or create an account to post a comment.

Sign up Log in