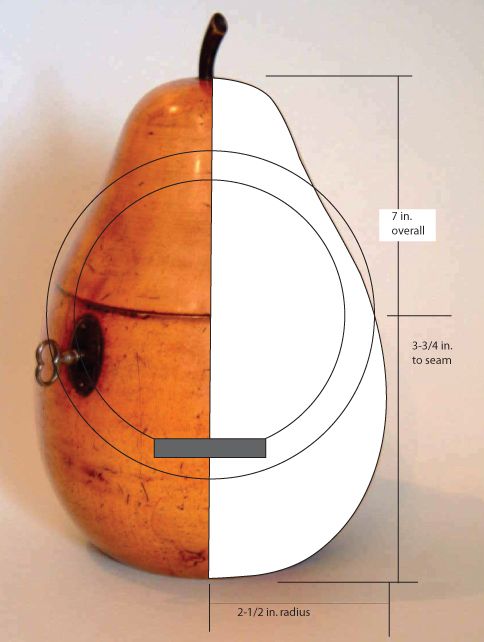

This is the original tea caddy I'm workng from. it dates from the late 1700's or early 1800's, and was turned from sycamore.

My wife Kate, an inveterate collector of everything from silverplate to pressed glass to lusterware pitchers to Chinese ancestor paintings to flow-blue souvenir plates to postcards of Teddy Roosevelt, recently took an interest in Georgian tea caddies shaped like large apples or pears.

The originals, popular in England in the late 1700s, sell for thousands on eBay and other auction sites. Too rich for Kate’s blood, so she asked if I could make her a reproduction.

The originals were usually turned from apple or pear wood, sometimes basswood, with hinges and a lock that were probably custom-made for each caddy and shaped to follow the wood’s curve. The insides were lined with thin tin plate. (The caddy I’m using as a model was made from sycamore.)

I needed only a few minutes to find an image of a caddy I liked (ah, the power of Google). Coming up with the materials for my reproduction took more time. The biggest challenge was the hardware, particularly the lock. Finding a curved lock was out of the question, so I searched for the smallest lock I could find. Whitechapel Ltd., in Jackson, Wyoming, had what I wanted, along with a handsome small hinge. Rather than use tin plate, I decided to gild the inside of the caddy (Peter Gedrys, a frequent contributor to Fine Woodworking and FineWoodworking.Com, gave me some invaluable advice about gilding, along with a few samples for practice).

Finding the wood came next. I’ve had good luck buying turning stock on eBay, and I wasn’t disappointed. I couldn’t locate dry apple wood blanks large enough for my needs (and I wasn’t about to buy green wood and try to dry it, hoping that it wouldn’t become too cracked to use). But I did find a seller with two large hunks of basswood.

Now, I was ready to make a plan. I began with the image of the Georgian caddy I wanted to use as a model, importing it into Adobe Illustrator. I scaled the image to the size I wanted (5 in. dia. And 7 in. tall), then traced half the image to create a template to follow on the lathe. Then I added circles sized to the caddy’s diameter where the top and bottom separate. I drew in a rectangle the size of the lockset I bought, to be sure it would fit. Plan B was to increase the thickness of the caddy’s wall if need be, to allow more room for the lock. Fortunately, though, the lock looks as if it will fit.

Coming up in chapter 2, turning and mortising.

Comments

Where do I find chapter 2?

Log in or create an account to post a comment.

Sign up Log in