Hi Matt and Asa,

I’ve been following along with the Getting Started in Woodworking video series that you have been doing. I am enjoying it very much. Thanks for doing it.

Regarding your latest episode on using screws and wood plugs: Whenever I see a woodworker working with plugs I think about a couple of old boatbuilder’s tricks. Wooden plugs are a very common thing on many boats. Especially so on wooden boats. Boatbuilders call them bungs. They don’t glue them in over screws. Instead, they bed the bungs in the holes with the varnish they’ll use to finish the wood. This eliminates any worry about a glue line that won’t take stain and if the plug needs to be removed later for a repair, it can be jacked out of the hole by driving a wood screw into it. The varnish will hold the plug just fine until you want to remove it. Then you can get it out wiithout damaging the surrounding wood.

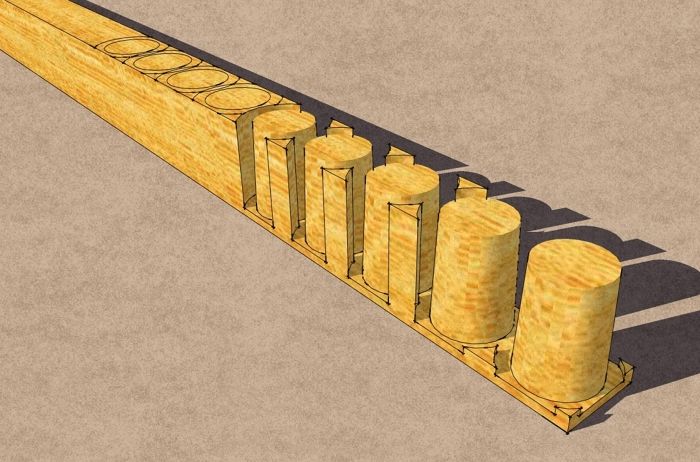

Of course it is important to align the grain of the plug with the grain of the surrounding wood. It makes the plug less noticeable but it also prevents some unsightly gaps around the plug. Plugs will shrink a wee bit and become elliptical. As you know, this ends up being very noticeable if the plug’s grain is 90° to the surrounding grain. To make it easier to insert the plugs with the grain alignment correct, you can cut the plugs in a narrow piece of wood. Make it just a hair wider than the plug and cut the plugs close together. Cut the plugs so they are still attached to the stick with a thin web. (See the attached image.) Don’t cut them free of the stick. When it comes time to install the plugs, you can dip the end plug in the varnish (or glue), stick it in the hole and drive it home with a hammer or mallet. This will break it loose from the stick. And maybe the best thing is that you don’t get the gooey stuff on your fingers so there’s less chance of smearing it on your project. (especially if you use glue)

Keep up the good work.

Dave

Comments

I'm trying to cut a circle into yellow heart and fitting it into a piece of walnut. I'm using a 4" diameter hole cutter. My problem is that when I drill the hole using the 4" hole cutter into the walnut the hole is too big. If I try using the next size smaller hole cutter the hole is too small. How do I allow for thickness of the hole cutter bit?

Log in or create an account to post a comment.

Sign up Log in