New Spin on Fan Inlays

Add pop to tops and other surfaces with handsome fans

Synopsis: Garrett Hack takes a modern approach to a classic inlay form, the quarter-circle fan. This is a motif used frequently on 18th-century Federal furniture, but it can appear bright and modern when used in nontraditional ways. Hack’s method is efficient and ensures uniformity. Instead of the traditional method of cutting and insetting each thin piece of veneer individually, Hack cuts and assembles fan rays in bunches, creates a thick “sandwich,” slices off the individual fans, and glues them into a recess. This article also includes design ideas for using fans and stringing to add spark to your furniture.

From Fine Woodworking #204

Most furniture makers aspire to have their work stand out, to be original in some way. That’s what inspired me to start using various forms of inlay in my work, from traditional cuff bandings to original Morse-code signatures in black-and-white stringing. They’ve all added uniqueness—and lots of fun—to my furniture.

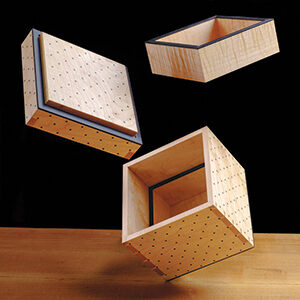

One of my favorites is the quarter-circle fan, made from ebony and holly rays. These fans appear frequently on 18th-century Federal furniture, where makers used them to brighten the façade of a piece with contrasting flourishes in the corners of drawers and doors, to adorn and connect the corners of a tabletop, or to decorate the back splat of a chair. I’ve used fans in these traditional ways, but I like to push the envelope, inlaying fans in surprising places, like backsplashes and table aprons. I’ve also altered the design and construction a bit. Traditionally, fan inlays were created with veneers of contrasting colors (whether shaded, dyed, or of a different species) cut and inset into a shallow mortise one ray at a time. The outer radii of these traditional fans often were scalloped.

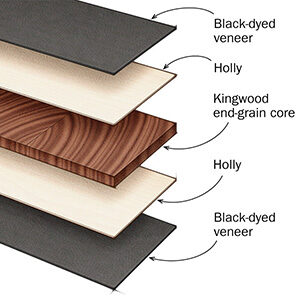

My modern approach to making and installing fans is efficient and ensures uniformity. I use thicker stock, with rays cut and assembled in bunches, and fans then sliced off the bundle and glued into a router-cut recess. Each fan has a smooth outer radius. For fun and flair, I add a small ebony dot at the tip. Wood movement is rarely a concern with these small fans, but their orientation should always be face grain— never weak end grain.

How to make a fan sandwich: When it comes to fans, I like the extreme contrast of white holly and black ebony, because both colors will contrast with most woods. Generally, the most appealing and balanced fan has an odd number of rays, beginning and ending with the dark ebony in lighter-colored woods or with the white holly in darker woods.

Making a fan sandwich sounds simple, but it takes considerable effort to assemble the small wedges accurately. Any slight mismatch of the rays is very noticeable.

Cut rays on the tablesaw—The fans shown here are delicately sized, so you don’t need a lot of material. Start by crosscutting 1-in.-thick blanks of ebony and holly about 1 1⁄8 in. long. Blanks that are 4 in. to 6 in. wide should yield plenty of ray stock for four or more fans, with room to toss any damaged pieces.

Glue each blank to a scrap block the same thickness and length, and about 4 in. or so long (see drawing, facing page). The scrap block will keep your fingers a safe distance from the blade as you cut the rays and will allow you to use as much of the valuable holly and ebony stock as possible.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Bahco 6-Inch Card Scraper

Whiteside 9500 Solid Brass Router Inlay Router Bit Set

Log in or create an account to post a comment.

Sign up Log in