Dry run. This is the first dry-fit with all the rungs, arms and the front and back in place. The cauls are mounted on a 1/4" MDF base that positions them. They are cut to an angle that compliments the angled sides. This gives me square, parallel surfaces for the clamps.

The rocker project is almost complete. Check out the photos above to see some of the shaping and fitting that happens prior to glue-up.

All posts on the rocker project:

Part 1: Mill the lumber and laminate the back rest

Part 2: Turn the rocker legs

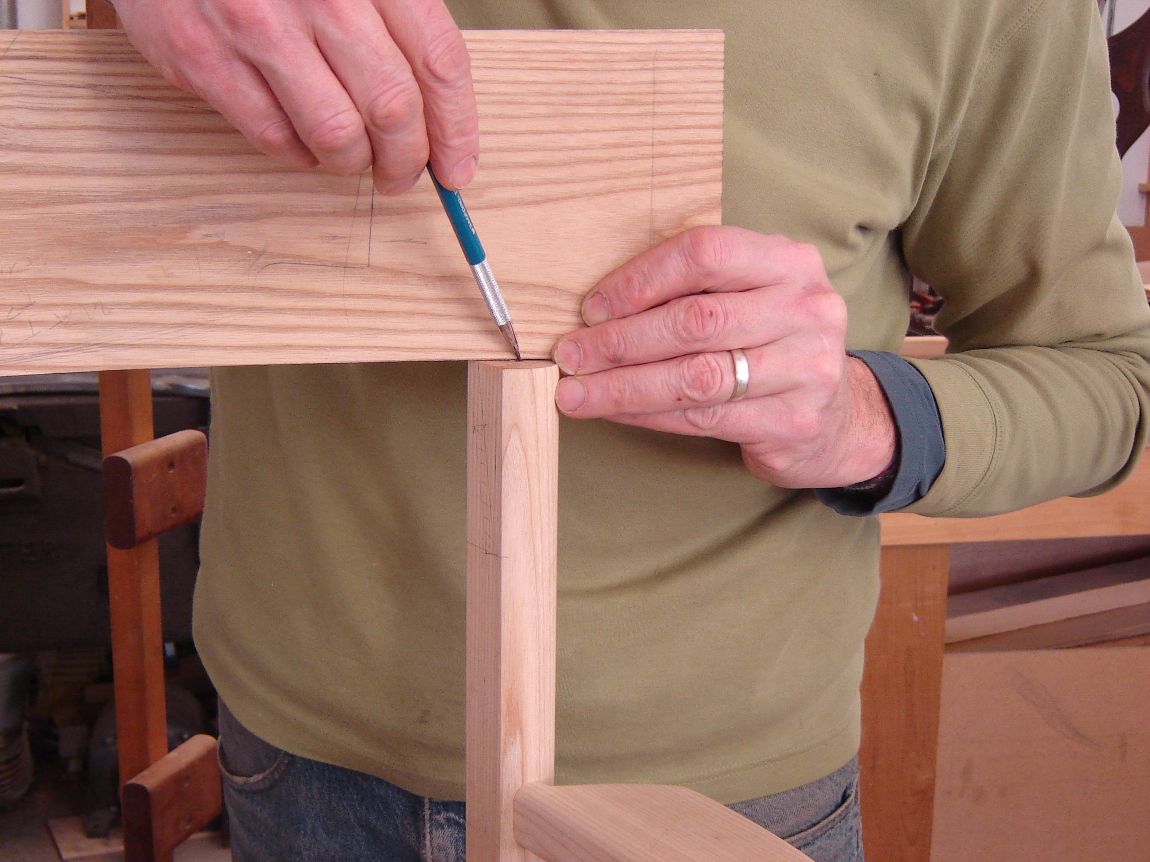

Part 3: The joinery

Part 4: Final fitting and shaping (above)

Part 5: Project complete

When everything is said and done, the rocker will look a lot like this:

Log in or create an account to post a comment.

Sign up Log in