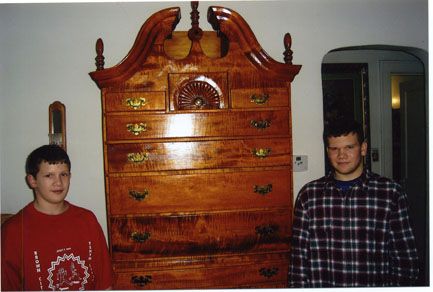

The boys at work (or is it play?)

One of my responsibilities here at Fine Woodworking is sorting the mail. The other day we received a padded envelope addressed to someone who no longer works here. In it were a letter and some photos of 2 teenaged boys working in a shop and a finished tiger maple Queen Anne Highboy. While at school, the boys–Nathan and Christopher–got involved in shop class and enjoyed it so much that instead of watching Saturday morning cartoons on TV they would watch Norm Abram on The New Yankee Workshop. One of Norm’s projects was a Queen Anne Highboy and the boys decided they wanted to take on the challenge.

Before they started the project, their father called Fine Woodworking looking for plans and guidance. He was grateful for all the help, so he wrote a letter of thanks once the project was complete. Here’s an excerpt:

Dear Kathleen:

You may not remember me. I was the guy who called you regarding an article that had run a few years ago in Fine Woodworking about a Queen Anne Highboy. And you were so kind to send us (myself and sons Nathan and Christopher) a copy from your archives of that series. Anyhow, after many months the boys finally finished their version of the historic piece. I have enclosed a few photos of the project in various stages right through completion. We hope you enjoy them.

I am so proud of the boys and their accomplishment. I was not sure if I would see this dream come true. But thanks, in part to you, a family heirloom has become the result. I might be carrying on about this, however words on these pages could never express my gratitude and joy in my heart.

Thank you again for your kindness, Jeff

Getting things like this in the mail is really nice. It is great to see the results of a phone call and in this case it is really great to see 2 brothers working so closely together to produce such a fine piece. (One of the boys hopes to go to the College of the Redwoods in the future). But the best part of all is hearing how proud the father is of his sons.

Comments

Awesome, just beautiful work guys, you all should be very proud! How and with what did you shape the cabriolet legs?

-Ace-

the legs were selected form steright grain common soft maple. Then they were cut to length, squared to 27/8 sq, layed out on 2 opposing sides (toes touching)then on the table saw the knee was cut to create a sharp corner on the finished leg then they were cut out on the band saw leaving the line, cutting the knee first the cut off knee was saved the ballance of the first cut was made leaving a bridge of 1/2" so the other could be cut with a square flat base then before cutting the other side the loose knee waste was double tabed back into place. (the post was not cut on the bandsaw) The next step was to turn the leg on the lath to create the foot. Next the leg was smothed at the spindal sander then the leg was sculpted with concave spokeshaves, cabnit scrapers and a shinto rasp sand paper till the desired effect was achived then with calipers and templates made for the firs leg the others were made in the same mannor and worked till they were all the same dimention. The final step was to cut the post at the table saw and finish the under cut with a back saw to get an absolute square post for a tight fit between the sides front and the legs. I hope this helps and thank's for your inquiery.

Thanks for the reply. I have only practiced a few legs. At the time didn't have a lathe and shaped everything by hand and was lots of work.

-Ace

Log in or create an account to post a comment.

Sign up Log in