Hot-Pipe Steam-Bending: Free Form Bending

Watch Fortune demonstrate this unique technique on a pair of salad tongs. Part two of a three-part video series.Watch Fortune bend a thin strip of wood to create a salad tong. He starts by making a profile of the shape he needs from 1/4-in.-thick hardboard or plywood. It is then easy to overbend the wood strips and let them spring back to fit the pattern.

|

More on Hot-Pipe Bending |

| Part One: Introduction |

| Part Two: Free-Form Bending (now playing) |

| Part Three: Bending Furniture Parts |

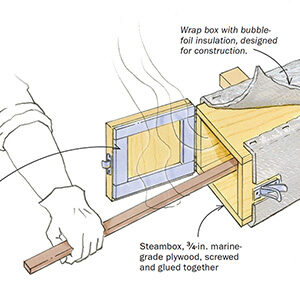

With practice, it becomes easy to judge just how much and where to bend. If you are not using green wood, it helps to soak the strips thoroughly for about three hours before bending them. Unlike laminating or steam-bending that relies on a form to provide the shape, this technique requires that you hand-form (coax, really) the part being bent to match the pattern. This can take from as little as a few minutes for 1/8-in.-thick strips to as long as 10 minutes if you are bending 3/8-in.-thick material. Success means getting a feel for just how much surface area has to be heated and for how long, and how much overbending is required to achieve the correct result.

Read more on Fortune’s technique in The Magic of Hot-Pipe Bending from FWW #205.

Log in or create an account to post a comment.

Sign up Log in