Hot-Pipe Steam-Bending: Furniture Parts

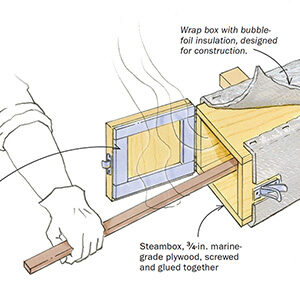

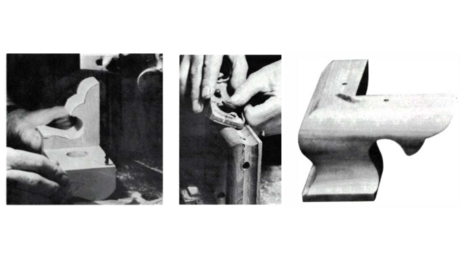

Learn how to bend thicker pieces of wood and get multiple parts to uniform shape. Part three of a three-part video series.Fortune uses hot-pipe steam-bending to create furniture parts, like the back splats of a chair. He shows how you can increase your success rate by holding a strap on the outside of a thicker strip as it is being bent. This helps hold down wood fibers that want to lift and create a deeper split. The strap should be just wider than the piece being bent, and should not come in contact with the hot pipe. Nylon strap used for banding boxes is ideal and easy to find, while wider strips can be salvaged from old lawn chairs or a lawn-chair repair kit.

|

More on Hot-Pipe Bending |

| Part One: Introduction |

| Part Two: Free-Form Bending |

| Part Three: Bending Furniture Parts (now playing) |

When creating identical furniture parts, Fortune uses a single large setting jig for uniform results. With the jig, the bent part rests in the setting jig secured lightly with clamps or tape. Air needs to reach both surfaces of the drying workpiece to prevent warping or cupping. Therefore, the setting jig should be a frame rather than a solid surface.

Once the parts have set to their new shape, they will have little memory of ever being straight. However, ends that are not restrained will have a tendency to move with changes in humidity. Parts bent this way also should not be immersed in water for any length of time, as they will straighten.

Read more on Fortune’s technique in The Magic of Hot-Pipe Bending from FWW #205.

Comments

This is very helpful and interesting. Never stop learning. Thanks for the gear instruction

Looks like some kind of gasket material or heat shield between the pipe flange and the wood its bolted to?

Log in or create an account to post a comment.

Sign up Log in