The Magic of Hot-Pipe Bending

An easy technique for bending thin strips of wood to virtually any shape

Synopsis: This is a very easy technique for bending thin strips of wood to virtually any shape. Better yet, the simple apparatus is made from a few hardware-store parts.

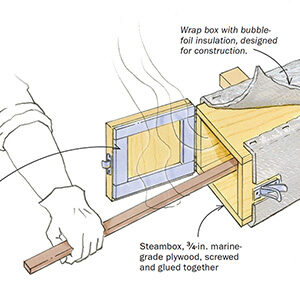

You simply hold a strip of wood against a section of metal pipe heated by a propane torch. Unlike steam-bending, there is no need to construct a large steam-box or substantial bending forms. Michael Fortune uses the technique to bend door pulls, curved moldings, salad tongs, back slats for chairs, and many other items.

From Fine Woodworking #205

This is a very easy technique for bending thin strips of wood to virtually any shape. Better yet, the simple apparatus is made from a few hardware-store parts.

You hold a strip of wood against a section of metal pipe heated by a propane torch. On the side in contact with the pipe, the lignin bond between the wood fibers is softened by the heat until it is pliable enough to bend partially around the pipe. Unlike steambending, there is no need to construct a large steambox or substantial bending forms.

The curved sides of musical instruments such as guitars and violins have traditionally been made this way, but I use the technique to bend door pulls, curved moldings, salad tongs (shown at right), back slats for chairs, and many other items.

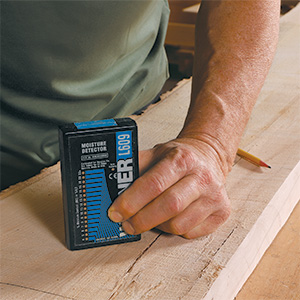

Most woods bend if the piece is thin: Unlike steam-bending, where only domestic hardwoods bend to any appreciable degree, you can use the hot pipe method to bend a broad range of species. As with steam-bending, straightgrained wood that has been air dried will bend faster, to tighter radii, and with fewer breakages than kiln-dried wood. You can use kiln-dried wood, just expect to break a few pieces and to take longer.

Woods that bend well on a hot pipe include red and white oak, ash, walnut, elm, hickory, and beech. Woods that bend with less success, particularly to tight radii, include cherry, maple, australian lacewood, Macassar ebony, imbuia, east Indian rosewood, mahogany, domestic softwoods, and softer domestic hardwoods such as basswood and poplar. Avoid bending curly or figured wood and burls; they break easily.

The thickest piece that can be bent is 3⁄8 in., and then only to a gentle curve. This is due to the limited depth that the heat from the pipe penetrates the wood. Heating both sides won’t help; it will just encourage the outside fibers to stretch and fail.

It is important to have consistent grain across the width of the piece. You might get lucky and find a wide board with consistently flawless grain, but I’ve found that 3 in. is about the practical limit in width. You need to make the blank only about 1⁄8 in. wider and 1⁄32 in. thicker than the desired finished piece, but if the piece is to be bent at the ends, it should be about an inch longer at each end to give locking pliers a place to grip.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in