Q:

I’m making a cabinet from cherry. After gluing up the panels and cutting the joinery, I stacked and stickered the panels. Unfortunately, they’ve warped. Why did this happen and is there anything I can do to correct it?

Jeff Huntington, Loudon, NH

A:

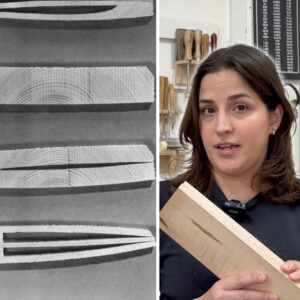

The moisture content and internal tension of properly dried lumber should be in equilibrium and the wood stable when you bring it home. However, there often is less moisture near the surfaces, and when you mill the board, you upset the balance and the wood can twist or warp.

To reduce this risk, wood should be milled equally on both sides, a little at a time, stickered, and then re-milled. This will slowly relieve the stresses and allow the moisture to equalize with the moisture in your shop.

Even with these precautions, wood still warps sometimes, but it’s not the end of world. I work with warped wood frequently. If the ends are secured, like on a dovetailed carcase, the warping can be taken out by the joinery.

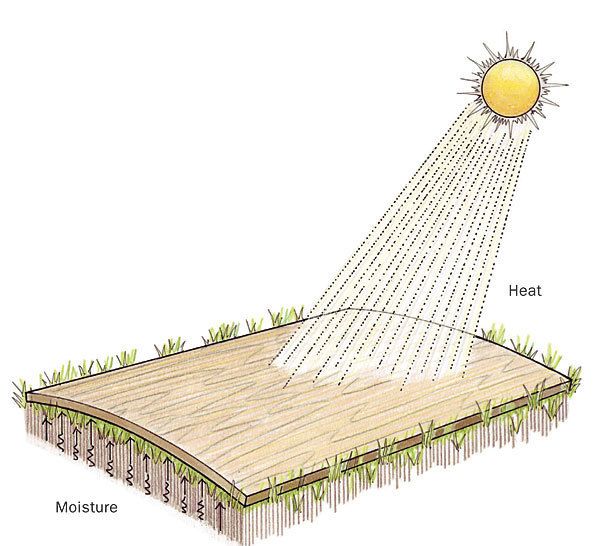

You also can remove the warp by placing the panel with the convex side toward a heat source and drying it back into shape. An old-timer I once worked with would toss a warped panel (concave side down) onto the lawn, and let the moisture from the earth and the heat of the sun take out the warp.

But your panels could warp again. After you get the warp out, assemble your cabinet quickly, before they get the chance.

Drawings by Vince Babak

Fine Woodworking Recommended Products

Stanley Powerlock 16-ft. tape measure

Estwing Dead-Blow Mallet

AnchorSeal Log and Lumber End-Grain Sealer

Log in or create an account to post a comment.

Sign up Log in