Traditional Oil Finish Recipe

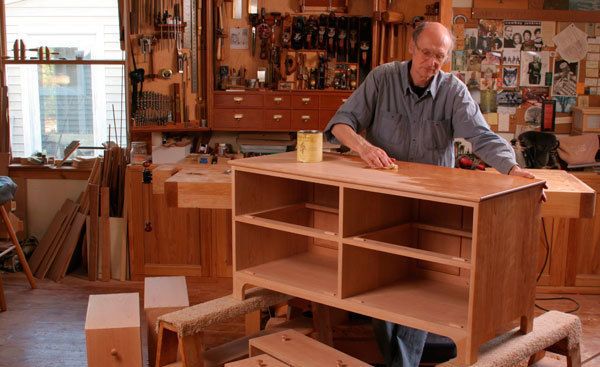

Professional furnituremaker Chris Becksvoort's go-to finish is simple and goes on easy.

Finish and application: Wipe-on oil and varnish

Skill Level: Easy

Finish Products: Danish Oil, Tried & True Varnish oil and spar varnish (whatever is at hand: McCloskey, Z-Spar, Epifanes) or polyurethane ( Minwax, Defthane)

Project Type: Shaker Chest of Drawers

Maker: Christian Becksvoort

Materials: Cherry

I prefer an oil finish because it is spot repairable and easy. The spar varnish or urethane helps the drying process and adds protection to the finish.

STEP-BY-STEP

1. Sand

I belt sand to 120, use a random-orbit sander for 150-, 180- and 220-grit, hand-sand to 220-grit and sometimes 320. Then I polish with 0000 steel wool.

2. First coat

Straight Danish oil, ambient temperature should be above 70°. Oil each piece (case, drawers, bottoms, tops) and wipe, being careful to remove all oil. Let dry for 48 hours, and then go over all surfaces with 0000 steel wool.

3. Second coat

Use a mixture of 2/3 Tried & True varnish oil plus 1/3 spar varnish. Wipe thoroughly, at least twice. Let dry another 48 hours.

4. Third coat

The same mixture of 2/3 Tried & True varnish oil plus 1/3 spar varnish. Apply and wipe thoroughly, and again allow 48 hours dry time.

5. Wax

I do not wax anything except the drawer runners and sides because wax encourages heat rings. Assemble all the parts, and wax drawer runners and drawer sides for a smoother glide.

Fine Woodworking Recommended Products

Diablo ‘SandNet’ Sanding Discs

Bahco 6-Inch Card Scraper

Comments

Dear Editors

I built this piece and I am very pleased with it. However, I noticed that two of the drawers contracted termites, not clear how. I have kept it in my woodworking shop and didn't bring it to the house yet. How I get rid of the termites? My email is [email protected]

I followed these directions to finish a cherry bookcase. 1st coat was a thin layer of shellac to control blotching. 2nd coat was straight Tried & True danish oil. 3rd and 4th coats were a mixture of 1/3 "Indian" spar varnish (expensive) + 2/3 Tried and True varnish. I waited at least 2 days between very very thin coats. Almost seemed like I wiped all the oil off between coats?!? But then after a few days you could see some of the oil that had settled on the cardboard the bookcase was resting on.

I have used Epifanes for outdoor tables. It's very thick so the first 3 coats are thinned if you do it by their recommended instructions. In the process listed above, would you thin the Epifanes if that's what you used?

I have just about completed a shaker style cherry chest of drawers. The drawer sides are poplar. Is it recommended to use oil/varnish finish on the inside of the drawers also or possibly something else like shellac? Planning to line the bottom drawers with aromatic cedar & I'm just trying to avoid the finish smell inside the drawers. Thanks for any suggestions!

Since it's been almost a year since you posted this, I'll assume you've found a solution that worked for you. The idea of coating/sealing both sides (edges and ends) of a board (after assembly) is to try and equalize moisture absorption/loss to reduce the chance of shrinkage, warpage, splitting, twist, cup & etcetera of your completed project. Your idea of shellac [de-waxed, 1 or 2 thinned coats] is a good one for your particular odor-free requirements. I was gifted a 30" x 60" x 1½" hard maple, butcher block trestle table a few years ago which had a cupped top because the manufacturer cut costs by only finishing the "Show Face". I disassembled it, stored it in my little shop and now, the cup has lessened and I'm about to cut it in half lengthwise, flatten and laminate the two halves together and turn it into the main part of a new benchtop almost 3" thick. Trust me, when the bench is finished, it will be given several coats of Watco Danish Oil on all exposed surfaces -top to bottom, inside and out - to keep everything as stable as possible.

There is absolutely no need to finish the insides or undersides of things. It doesn't stabilize anything, and won't stop it from moving.

Thanks John. My goal was not necessarily to keep the wood from moving but to have it move as consistently as possible without too much finish smell. I did use the shellac inside as indicated and, so far so good...

Thanks for the reply User.

I did use a shell "wash" on the insides of the drawers along with the recommended tung oil/spar varnish for the outside of the chest & it worked out fine.

Log in or create an account to post a comment.

Sign up Log in