Setting Up Shop: Machine Number Two

Learn why this woodworker opts for a bandsaw rather than a tablesaw as his second major machine acquisition.

Resawing to make book-matched panels is one of the many tasks accomplished with the bandsaw.

I suggest the second major machine acquisition should be a good quality bandsaw. No, not a tablesaw, not in the number two slot. True, the tablesaw rips and crosscuts very well but it is far less versatile.

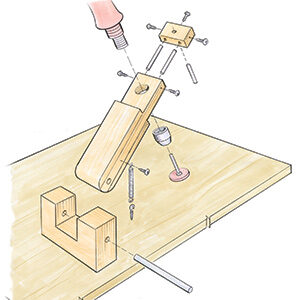

The great freedom afforded by a good bandsaw can change your relationship to wood. Here is a sampling of bandsaw work:

- cut curvy legs from 12/4 mahogany

- resaw a 10″ figured board into book-matched panels

- make your own 3/32″ veneer

- select out furniture parts from stock irrespective of their orientation to the original edge of the board

- cut tenons

- cut and dry some wood from a tree felled in your backyard

- try some sculptural work

- rip laminates for bent lamination work

- cut out cartoon characters and toys for your kids

A bandsaw will generally not rip as cleanly as a tablesaw, but with an excellent blade, it does a surprisingly good job that can be cleaned up and trued reasonably easily with a hand plane. For clean, accurate, consistent crosscutting, it must be conceded that the tablesaw is the clear winner. Still, the shooting board can take care of that issue. If I had to give up one of these two machines, there is no doubt the tablesaw would go because the lack of a bandsaw would be far more limiting to my range of designs and work.

The bandsaw takes up much less shop space than a typical tablesaw. There is an additional, hard-to-define virtue of bandsawing. It is the machine work that I liken most to hand tool work. I feel in touch with the cutting action and in control of the work, unlike with the tablesaw where, after the setup for a cut, the machine essentially rules. A bandsaw is also much more fun to use than a tablesaw, jointer, or planer.

I suggest a steel frame saw in preference to a cast iron version, with at least 10″ cutting height, preferably 12″ or more. Lower-priced steel frame saws in the $800-900 range, such as the Rikon 10-325 or Grizzly G0457, are not more expensive than a quality cast iron model with a riser block. Better still, move up to a bigger saw such as a Minimax or Agazzani.

Build your woodshop team by adding a quality bandsaw to the roster early on, and you are likely to increase your woodworking skill, fun, and versatility.

What’s next? I’ll leave this question open for now, but I think the tablesaw is in line behind the router table. If you’re really hooked on woodworking, you can work your way down the wish list in due time. Happy woodworking.

More in this series

• Which Machine First and Why

Comments

Nice article, Rob-

I'm in agreement an almost all of your points until you get to vertical capacity. You emphasize at least 10" preferably 12" or more.

I see no advantage to spending a lot of money trying to achieve a cutting height that will be seldom used.

I do a lot of resawing and find that for gluing up panels I avoid wide pieces due to the likelihood of warping, especially in the over 8" width glueups. Thinner panels of 3/4" or so are even more vulnerable.

I use a 17" Griz that will cut up to 9-1/2" but almost always limit it to 8" for that reason. I have never needed panel segments wider than 9".

The first big machine in my shop was a bandsaw. I used it for ten minutes, turned it off, unplugged it, and went back to the store for my second and third machine purchases the same afternoon. The second major machine in the shop was a stout dust collector and the third was an air filtration unit.

You might not think of a dust collector and air filtration unit as traditional "shop machines," but hands down, they operate more hours in my shop than anything else with a plug. They are not as glamorous as the tools with blades, cutters, knives, and inserts, but they make the other tools cleaner, safer, and more comfortable to use for extended periods.

If you are new to woodworking, I think most of the capabilities of the bandsaw you list aren't going to be attempted. You will probably start out building boxy projects like dressers and tables with square legs, etc. So, for the beginner I think a tablesaw would still be your best bet. An inexpensive jigsaw will get you by until you graduate to higher skill levels. Now, if you're becoming a better woodworker and want to move up to better quality equipment than you probably bought when you were starting out, I agree with your purchase order. You will have the less expensive machines you already own at your disposal as you upgrade your shop.

I still think you're nuts! The Table saw doesn't even make it in the number two slot on your list? You might as well put Oscillating spindle sander down as machine number three. It too is a "machine that does a very good job, at a very hard task!" Like the Planer you had mentioned as machine number one.

Dustdog in 100% correct. No one who is buying a bandsaw as their second machine, will ever do anything mentioned on your list of "bandsaw work." And besides that, I can't believe you didn't choose a Jointer as machine number two. The Jointer and the Planer complement each other. There is no sense in having one without the other, especially if you are building furniture. The two together are a must. But still, no one should buy any of these machines, until they get their Table saw set up.

To clarify, the question I raised was which major machine to buy first (and second). Judging from the interest generated, this clearly seems worthy of discussion. I feel it’s great to hear opinions from passionate fellow woodworkers. In agreement with many of the comments, the answer surely depends on the types of projects a woodworker intends to make. This, along with personal preferences in working style and other factors, precludes a definitive answer. The main point is that new woodworkers can hopefully benefit from the many opinions offered.

Regarding the roles of the jointer and planer and the "which machine first" question, I suggested in my post that the necessary flattening of one side of a board can be done by hand reasonably quickly and more easily than thicknessing a board by hand. The latter task still remains for hand work to achieve the desired thickness if you have a jointer but lack a planer (unless certain rigs are attached to the jointer which I feel are awkward).

My suggestion for machine number two, the bandsaw, is also a subjective choice, based largely on the versatility and creativity capable with this machine, even by novice woodworkers.

For the record, I happily use my Saw Stop cabinet table saw, jointer, and routers. I like them almost as much as I like my hand tools!

As a beginner woodworker I was fortunate enough to purchase a used collection of power tools from one fellow. For $650 I got a 14" band saw, 6" jointer, 12" thickness planer and a drill press all in one shot. None of which are exceptional pieces but they all work just fine. I recently sold my jointer and bought a Lee Valley 22" jointer hand plane with a fence. Because my projects are few and far between (and there is no production deadline) I'm realizing the ease and pleasure of using hand tools when I can. I love precision power tools as much as the next guy but the premium expense of the tool itself and the residuals like dust collection, space, noise, safety precautions and even electricity are so high that I'm starting to think outside the box. The jointer I felt was taking up way too much space and for the one job that it did, I feel I have replaced it with a more versatile and pleasing tool that I love to use (and is actually beautiful to look at). Now I'm starting to feel like I was taking in by the hype of aquiring power tools and neglected to consider how enjoyable hand tools are. Just my $.02 oh, and yes, I use my band saw way more than my table saw.

No No double NO. Sorry Rob, but I completely disagree with your advise for "New woodworkers regarding what machine to get first". I would have agreed if you had listed Dust collector as first machine.

Everything beyond that, really depends on the type of woodworking! Means, there is no simple answer what machine to get in which numerical order.

Running that dewalt planer inside a building without dust collection is outright crazy because its a major health hazard as we all know. Imagine a "New woodworker" takes your advise and runs black Walnut or Mahogany or other toxic woods without dust collection. Wow, that be winner, next stop for him could be hospital.

To run a lunchbox or construction side planer how I call them, outside a building without dust collection is a different story, but never indoors!!!

I love the bandsaw, because it's easy to control and one of the lesser dangerous machines, it does things you mentioned (Veneer, thick stock rip or curves) However, tablesaw rips faster and nicer, plus is more versatile than a bandsaw and gives a new woodworker many options for projects. Even though you can crosscut on tablesaws, it gets awkward with longer boards. Especially if the tablesaw is not a heavy duty cabinet type. For crosscutting a mitersaw might be best.

So while a bandsaw might be right for you, it wouldn't if you wanted build cabinets out of 4x8 sheets.

Again, I dont think there is a "one fits all" answer to what machines to get first.

In my opinion, its best to start with either hand or powertools and safe up some money, and once the skills progress buy multiple machines based on the type of woodwork you do.

Log in or create an account to post a comment.

Sign up Log in