I always liked the idea of having a shaving horse. A few years back I built a set of windsor dining chairs and shaved the spindles with my draw knife and spokeshaves. Back then I didn’t have a shaving horse so I ended up using my woodworking vise to get the job done. While the vise worked, I knew that using a shaving horse would be a lot more comfortable and a lot more fun. I’ve seen shaving horses for sale on different websites but the problem was that they were over $500 a piece. I knew that wasn’t going to fly so I had to make my own.

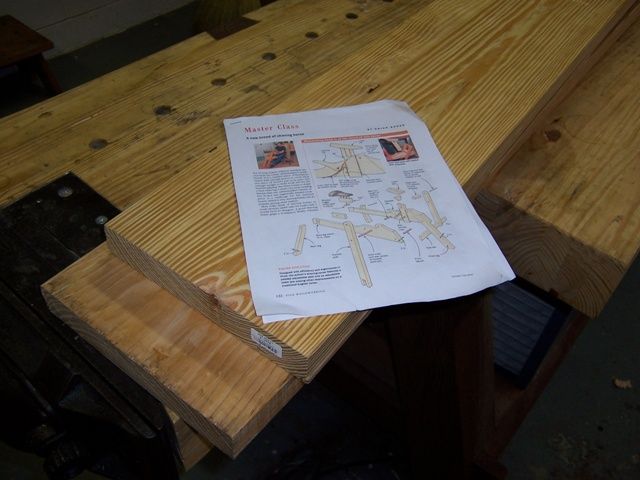

Then one day I ran across an article Brian Boggs did for Fine Woodworking. The shaving horse he made was simple and straight forward to make. Right then I knew I had my plans. The one problem that I saw was that he used 2″ thick material to make his. I wasn’t about to splurge big money on 2″ thick ash or maple so I decided to make mine out of good ole southern yellow pine.

I went to Lowes and picked out two pieces of 2x10x8’s that were as clean as possible without any knots. Total cost was $14.73. While Fine Woodworking showed “plans” for the horse, they didn’t go into great detail about how to actually build the horse and a lot of detailed measurements weren’t even given. So I just eyeballed where I thought edges should be and built the horse as close as possible to Brian’s. (For a new, full set of shave horse plans, see the link below.)

Building the horse wasn’t complicated at all and it only took me a weekend to make. I milled the body out, shaped the back legs and made an extra long front leg. The nice thing about using a 2×10 is that you can cut both back legs out of one piece that’s 21″long. Once the back legs were installed, I leveled them with a compass and shaped the feet so they would sit flat on the floor. Then I took the front leg and leveled the horse, marked the top of the leg and trimmed it flushed.

The only caveat of using 1 1/2″ stock as opposed to full 2″ stock is that the head becomes narrower. Brian’s bench head is 5 1/2″ wide due to the fact that he had three 2″ wide boards glued together. My bench head could only be 4 1/4″ wide due to three 1 1/2″ pieces glued together. Fortunately I don’t think that’s a big concern due to the fact that mostly what I’ll be shaving are spindles.

The one thing I did differently from the plan was Brian used a bicycle tire tube to act as a spring for the key. I didn’t have an old tube lying around and didn’t feel like buying a new one so I ended up using a big fat rubber band instead. While it works, I’m sure the tire tube would work much better since it would have more spring to it.

I also just shaped the seat using a chair shave and spoke shave then sanded it smooth with a random orbital sander. Brian wrapped his with leather which gives his horse a real nice look. I did however glue a piece of leather onto one side of the hold down bar so that the horse would grip the stock better.

All in all I’m very happy the way the horse turned out and I can even take it apart for storage or to travel with. Now I just need to find me some fresh cut logs to make a chair.

For a full set of plans to build a shave horse from inexpensive pine, check out this article by Tim Manney.

Find more about Shaving horses in FineWoodworking.com:

Comments

Hi Mike,

Assuming that you've had a chance to use it are there any changes/modifications that you might consider? I like the idea of making it portable, i.e. removeable legs.

I'd also like to adapt it for use as a carving bench, uh horse.

Hi Bob,

I've played around with it a lot and so far so good. I really can't see any way it could be approved upon. Brian did a great job designing it. The biggest caveat to the horse is the size of the head. Since it's only 4 1/4" wide, I can't really stick big stock (like a chair seat) in the horse.

As far as a carving bench incorporated into it, I guess you could remove the arms and make a new wide head with hold down clamps on it and stick it through the horse body. ???

Thank you so much for this. One of my issues with building a Shaving horse has been my lack of space. I knew it would have to sit out side most (all) of the time. With the simplicity and low cost of this design, I now have no excuse for not finishing the two Windsor chairs I have started. Actually at the moment they are windsor stools, with some six foot split oak logs propped up against them which were intended for the spindles. I believe, if I use copious amounts of oil based stain, this horse might last a long time, even outside. I sure can't see why 4 1/4 inch wide would not be plenty.

Mike,

Thank you for sharing your tips on your design of this shaving horse.My Dad has wanted one for years he is 79 we are starting a new project building the shaving horse.

Thank's Again

loudsaw

the design of the horse is great, have any comments come in from the spoon and bowl makers. it should work great for spindles, Briain and community any suggestions for using the horse to do seats??

what if you used an old chair seat with a back on it and make it adjustable....slide forward or backward for differnt users leg length?

A very clean design. I like the stopsaw in the background...very nice..Thank you for sharing..Cheers

That sure looks like treated lumber. Could it be???

Log in or create an account to post a comment.

Sign up Log in