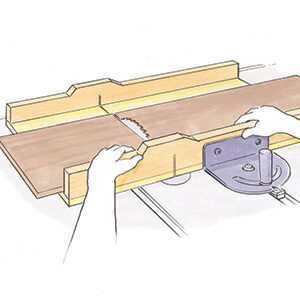

The technique that started it all: peening the bar of a miter gauge with two hammers.

We received a lot of letters about the dangers of hitting hardened steel with a steel hammer, sparked by a photo in the Fundamentals department in issue 205. After the author of that article, Steve Latta, copped to doing a no-no in the Letters column in issue 206, we ran a clarification in our most recent issue, citing an episode by the Mythbusters that supposedly debunked the myth of hammer-on-hammer dangers.

But the debate goes on. Robert Geers, a reader from Cedar Key, Florida, claims the Mythbusters are all wet, and says, in fact, that the dangers are real.

Hammers Striking

I was one of those who wrote in regarding striking the faces of hardened hammers together, so when I saw the “Clarifications” note I went to the site and searched out their tests. Or should write “Tests” in quotes, because they were not logical, and when they said “The hammers began to chip” but still declared it to be a myth, they missed the whole point.

Striking two hammer faces together, especially if swinging one at the other, places the likely “Chip” on a plane with the eyes. Only a small chip is necessary to do real eye damage, and having seen any number of chipped and abused nail (carpenters) hammers I KNOW the chips had to go somewhere, and they did not fall off while the hammer was in storage.

As a Woodshop teacher of 34 years, I know what I’m talking about on this subject. A hardened hammer, which all nail driving hammers are, WILL chip if abused by striking a hardened steel surface, maybe not the first time, but it will chip, and the resulting chips are dangerous.

I have no “Dog in this fight”, except the long standing desire to keep my students safe. And your statement of “gentle taps” is like being a little bit pregnant. The “MISS-Busters are , in my opinion, quite wrong on this.

But as my students would sometimes say, “Whatever”.

Comments

If you are going to hit the face of a ball peen hammer .... use a brass hammer, if you have one, or a couple of pound piece of mild steel bar stock. And use eye protection.

I do agree with what Myth Busters are saying, in the context it is said. The odds of a hardened hammer face shattering another hardened hammer face and a chunk of it being able to impact with lethal force is pretty slim.

There is also a lot to be said about the text of this article. It will eventually shoot off chips that can cause injury and if that injury is to an eye, you'll have a good chance of becoming a eye patch wearer. And unless you're a pirate, it isn't a good look.

As a roofing contractor, for many years, I have seen many hammers shatter, from being hit on other metal surfaces. One shard, stuck in one of my guys arm. He bled pretty bad, so we rushed him to the doctor. I,m talking nail hammers, not ball peens. Thanks

No, they did not miss. The myth was whether or not a hammer would "explode with lethal force" when striking another hammer or an anvil.

That simply won't happen.

It may chip, and they noted this in the episode. IIRC, they even stated that the chips could be dangerous. But it's not going to explode.

Really, listen to what they are testing, not what you think they are testing.

Well, I don't know about the Mythbusters, but I have a .22 caliber bullet sized hunk of hammer in my left bicep.

While working in a coal mine in PA in 1975 my boss was trying to break a flight chain. He place the peen of a hammer on one of the pins and smacked it with another hammer.

I felt a jerk in my arm and saw a hole in my shirt. When I got to the hospital I was told that the fragment was embedded too deep to remove and that I would be OK if it were left in.

Never had any trouble with it, but to this day I'll NEVER hit a hammer with a hammer.

I can't help but wonder if perhaps this happens more often when striking a newer hammer with an older model. Has the quality of steel changed? The hardening process? Would it be the newer steel causing a chip in the older tool or vice versa? I've heard opinions from both sides of the spectrum. And because of that, I'm building a rig and breaking out the slow-motion camera. With any luck, I'll be able to pull off something interesting. Please keep your fingers crossed!

Cheers,

Ed

I cringed at the picture of peening a miter bar on a TABLE SAW. That person has no respect for tools.

Caution must be used any time you strike two pieces of metal together. This is especially true with hardened steel objects. I have seen many workers requiring the services of a doctor or nurse because a piece of steel flew off a tool and lodged in their skin or eye. This is one of the reasons you are taught to grind the heads of your chisels if they are mushroomed. This condition invites a spall to break off and possibly injure someone. Always wear the proper clothing and safety equipment.

I know a hammer will shatter and I have the scar to prove it.

I did not hit the face square and a chip flew off and severed an artery in my arm. Luckily it didn't hit my eye or an artery in my neck.

The whole face of the hammer had fine cracks after that and was not used again. I think another blow and the whole head would have shattered.

I have seen a few hammers shatter in my time but never explosively. Poor choice of words. The idea of showing this practice at all is stupid. Not ignorant.

Why do you think the striking end of all steel chisels, punches, etc. are not hardened? Even then if the end gets mushroomed over too far it can make pieces fly.

Hey you! Put your safety glasses on! You'll see longer.

I saw the Myth Busters episode about hammers exploding. They used brand new hammers for the test. I believe that it is old well used hammers that are the greater danger of having a catastrophic failure.

When I was sixteen I was making a jig for my dads tablesaw. I was using a piece of cold rolled steel to go in the guide slot. Using a large ball peen hammer to strike a small ball peen hammer to ding the steel bar to fit the guide slot better. The small hammer failed. One piece hit and penetrated a full one gallon paint can. A second piece went through a window. The rest of the hammer face landed at my feet. The peen end was still attached to the handle. Since the paint can and the window were about 135 degrees apart, from where I was working, I think this qualifies as an explosion. I later found out that the hammer that failed had been my grand father's. It was estimated to be about eighty years old and had seen a lot of use.

I now have two rules about striking one hammer face with another. 1. DO NOT EVER DO IT. 2. When in doubt see rule one.

Hammer head to hammer head is not safe. I am still carrying a piece of steel from the head of a lathing hatchet in my left hand from a stupid mistake 50 years ago. Could have been much worse. I could have lost an eye. Just don't do it.

Just after the Mythbusters show, a friend of mine who didn't see the episode showed me a puncture wound on his left hand from which he had extracted a piece of hammer face that shot into it when he hit it with another hammer.

I and several other friends have had the same experience over the years. Mine was in my shoulder with the metal piece buried 1/4" below the skin. Glad it wasn't my eye.

This happens often enough to deserve the rules that GilbertAC posted above.

So... Practice so you can hit where you want with your hammer, then use the peen, or ball, end of your hammer to peen or shape the bar of your miter guage as needed. That's what it's for. The only time I know of to use two hammers at once is in shaping sheet metal with one specialized hammer as a backer on the oposite side to that which is struck,and this is a special hammer whish is never used for striking.

Hey everyone listen up:

The picture you see above is okay to do. I have been doing this for years with nothing bad happening. People come right next to me and watch, nothing happens. The mythbusters show was absolutely correct in what they said and the test methodologies. But the one fact the no one has ever thought of, except me, is why isn't anyone asking the hammer manufacturers for there opinion.

You know what they would say: Don't stike two hammer faces together. Why, cuz it is there for liability reasons. THe chance of that happening is slim to none.

lates

As in the case of many of the comments posted, I too, have been cut by flying pieces of metal from a hammer strike on metal.

As to the original image, I cringed twice when I saw it. First, the man is pounding on his saw table! This is not a workbench; this is a finely tuned (hopefully) woodworking instrument. Second, as your readers pointed out, hammer faces should never be struck together. While it is doubtful that an explosion would occur, chips can fly at explosive speeds, and pierce body parts.

Finally, instead of using a ball peen hammer, for the the process of removing play from the miter gauge (I assume that is what he is doing in the picture) I suggest using one hammer, a center punch and a solid flat work bench.

Striking the side of the bar with the punch will dimple it and gradually tighten the bar in the slot. Go slowly and check the play until satisfied it is snug enough.

As an ols metal fabricator I see one is a ball peen and has a diferent temper than the framing hammer. So, no problem.

The situation in the picture is acceptable because one of the hammers is a ball peen which has a softer face for striking tempered steel chisels. If the picture showed two claw hammers I would have a problem and feel it is a safety hazard, again because of the face hardeness. I have seen claw hammers use and have seen the face crack or break when not hit squarely.

Can't tell from the picture if he is wearing safety glasses or not. In my shop the first activity upon entering shop is to put on safety glasses.

I wouldn't be peening on the saw table either, but I would guess that probably he is just taping the peening hammer, not swinging at it! Probably not hard enough to shatter it or chip it! if he has to swing the hammer to peen, he is using the wrong tool!!!

I can tell you that this is NOT a myth. I still have a piece of the hammer head that shattered deep in my arm. The other piece clipped an artery on the inside of my elbow badly enough that it needed to be stitched, after the piece was removed. My father-in-law, Bert simultaneously managed to get another piece of the shattered hammer head in his knee. Bert was a doctor so I was lucky enough to have him do the surgery on me after we drove to the ER, but he had to bear the jokes of his peers while they fixed him. The culprit was a half hatchet that he was using to split wood while striking it with a large old ball peen hammer. The accident happened about three seconds after I said, "I don't think it is a good idea to hit that with the hammer."

One of the factors that is being missed here is energy. When a hammer is swung, it contains a lot of kenetic energy, that's what makes a hammer effective. If you hit two hammers together, that energy has to go somewhere. Some of it will be transferred to the kenetic energy of the rebounding hammer heads and the remainder will be used in distorting the steel in the heads and will eventually wind up as heat. Given enough energy, you will distroy anything! Just look at the kenetic energy anti-tank weapons.

My wife was unaware of the danger of striking hammer to hammer. I was at work when she did that deed in the barn trying to "help out." An hour later when she took off her glove the blood poured out and her hand was swollen almost round. A hand specialist had to be brought into the hospital OR since the chip cut the artery and was partially severing a nerve. The specialist warned that he had to operate but there was no garantee she would not lose the use of the hand. Almost 25 years later and her hand is still in pain, sensitive to cold, and lacking full mobility. My wife was a journalist and teacher that USED to type 140 words per minute.

"Explode" like a bomb? Maybe or maybe not. Knock off a flying steel projectile capable of inflicting injury and pain? Most certainly!

My brother in law, had a hammer chip and send the piece into his eye, hitting two hammer faces together. I would say this is a bad idea.

Another question comes to mind: "Why would anybody be peening using two hammers?" Seems to me that both should be hung up if you can't peen a reasonably straight line down the middle of a 5/8 strip. If desperate to bruise indirectly make up a punch, and get it off the table. The man needs slapin' for having no respect.

Like many others, I am on the side of safety. I'm not sure that the hammer or hammers will 'explode', but will certainly chip - as have found out. I still carry a small chip near my knee after banging two hammers together as a child (some 50 years ago). It could have been an eye or something else harmful. Two metals with different tempering might be a different matter.

In formal logic all it takes is one negative example to disprove the generality "that nothing can go wrong -- it's OK".

I have the X-rays taken before both MRI's that confirm the piece of the claw hammer head is still in my arm.

Case hardened claw hammer heads are very wear resistant against relatively soft nails. BUT the process leaves a brittel layer that is prone to fracture by impact with a through harded surface.

A friend of mine (now sadly passed away), had an extreme version of this happen to him. No fault of his own, and the police were involved for investigating if it was intentional...

A hydraulic press (iirc, 250T) had a cube of hardened steel left on top of a hardened steel tool, you guessed it, the top tool came down on it. The cube would have been a couple of inches high, the tool clearance about 1.5mm... It "shattered explosively" in my opinion, leaving him with a hole in his throat - about the size of a U.K. 5p piece, requiring surgery. He died from a completely different accident involving alcohol and a car (which he wasn't driving).

ANY hardened steel tool should be treated with respect, as you can drop them on toes, and cause injuries - that's not travelling too fast either...

I've never had it happen but I have no doubt that striking two hammer heads together can cause a piece to chip off of one or both. Explode?...hardly.

After 36 years of working on and around drilling rigs, I've seen all types of hammers...from 16 oz. claw hammers to 16 lb. sledge hammers used and abused in every way imaginable. I've never even seen one chip, much less explode.

Besides, there are few actions in a woodworking shop that someone will not consider unsafe. Practicing common sense safety is a good thing but seeing or imagining danger around every corner becomes a bit jaded after a while.

I've never had it happen but I have no doubt that striking two hammer heads together can cause a piece to chip off of one or both. Explode?...hardly.

After 36 years of working on and around drilling rigs, I've seen all types of hammers...from 16 oz. claw hammers to 16 lb. sledge hammers used and abused in every way imaginable. I've never even seen one chip, much less explode.

Besides, there are few actions in a woodworking shop that someone will not consider unsafe. Practicing common sense safety is a good thing but seeing or imagining danger around every corner becomes a bit jaded after a while.

I've never had it happen but I have no doubt that striking two hammer heads together can cause a piece to chip off of one or both. Explode?...hardly.

After 36 years of working on and around drilling rigs, I've seen all types of hammers...from 16 oz. claw hammers to 16 lb. sledge hammers used and abused in every way imaginable. I've never even seen one chip, much less explode.

Besides, there are few actions in a woodworking shop that someone will not consider unsafe. Practicing common sense safety is a good thing but seeing or imagining danger around every corner becomes a bit jaded after a while.

Mythbusters wrong?! Impossible! What they were testing was the myth that the hammers would explode, and they didn't, no matter what they tried. They did show that such abuse would chip the hammers, and they concluded that stiking hammer heads together was not a good idea.

It doesn't take a genius to realize that hitting one hammer head with another is dangerous. As always, common sense should prevail.

I don't care what "Mythbusters" have to say. My dad came home from work with a black eye with a red sclera (the white of the eye)when I was in high school. He had a piece of steel lodged in his brain from hitting 2 hammers together. The fragment grazed his eyeball, passed through his scull and stopped about 2mm into his brain. He suffered seizures for about 5 years after the incident (they mysteriously went away after that, never to have another seizure the rest of his life).

I was an Industrial Arts teacher and that was one the rules in all the text books, don't hit hammers together. The examples always showed chips flying off and gave the dangers that could happen. I don't know about exploding but I would say it is possible after reading the stories submitted.

If a person needs to do this a piece mild steel or brass needs to be used. The risk isn't worth it.

Peening material is a different process than striking hardened seel faces together with force. Peening requires controlled steel to steel contact,often with an allowed bounce of the peening tool itself,BUT the strike force is not great. Other than the risk of life itself,it is not dangerous except in the minds of some who worry about such things.

HOWEVER!! Let me also say that a sharp hard steel/hard steel blow with heavy arm strength force will indeed produce shrapnel that will penetrate human tissue with the greatest of ease. I learned this as a young man the hard way--resulting in having a thumbnail sized divet from a hammer face surgically removed from my forearm--ruined my good Plumb hammer but the Bluegrass survived.

I spent the past 25 years working in the metal working trades so know a little of metalurgy. First off, most hammers are not that hard relitively speaking so chipping is unlikely. Second, if they are hard enough (and I would say too hard for the purpose they serve) then your safety glasses should protect you. What? You don't wear safety glasses? Well then, shame on you. Typical carpentry/woodworking presents enough hazards to warrant wearing them. Do you really care whether you lose your sight to a wood piece or a metal piece?

Aside from all this, you'd have to hit the two hammers together pretty hard to create a chip and likely it would not occur on a single blow but after a fair number of strikes. Me? I'd just settle for the proper tool. A steel centre punch. But still wear those safety glasses.

I learned the hard way. I was lucky. I only ended up having surgery to remove the piece of hammer head from the back of my hand. A co-worker witnessed a guy lose his eye from a shattered hammer head.

For those of you that think it is safe, I put you in the category of the people who drink and drive. You may be lucky and never get caught or have an accident, but many are not and pay the price.

By the way, I am a shop teacher. I teach my students that the myth busters is a good show not to watch. I used to watch it until the hammer episode, then I realized these guys are NOT experienced scientists, they are only show people trying to make a buck.

Using two claw hammers one of my brothers hit them face to face to drive the claw of one under a nail head to be removed.

A b-b sized pellet from the hammer head flew across the room and hit another brother in the eye. The impact knocked the second brother off his feet and his impact with the wall broke through the plaster board.

Result: emergency surgery and loss of sight in that eye.

Chips and shards are real. They occur because forging steel turns it into a crystal, and all crystals (even diamonds) have faults, which are weak lines in the crystal matrix of iron and carbon molecules. (The most fault-free forging is supposed to be the jet engine compressor blades in fighter aircraft -- 24 inch long faultlessly-pure crystals of steel! That keeps them from fracturing and flying apart at 30,000 RPM.)

Since we can't afford $20,000 hammers, ours have some faults. So how can hitting together any two forged, hardened, tempered things ever be safe? It can't. That is why only the cutting edges of cold chisels and pin drifts and other striking tools are hardened and tempered. The haft (the head or top) of the struck tool is left soft to deform (mushroom) well below the cracking threshold of the striking tool.

The man shown striking a peening hammer is just using the wrong tools. He can use the flat face of a forged hammer to strike a round peening dolly (e.g., a Dagger CP560) or a convex dowel drift (either of which, of course, have soft hafts). For most of us, the best (cheapest) solution is to use our brass or bronze hammers (for peening, use an 18 to 24 oz head) to strike the ball peen hammer. Both the brass and peen hammers should be stored WITH your struck tools.

By the way, peening is a fitting operation, so the miter gauge must be peened while in the grove. The commentator who thinks this a problem is wrong.

Remember, using a bronze or brass hammer means that you won't damage struck tools, you won't create sparks and you won't have to worry about high-velocity steel shrapnel. Afterall, it's supposed to be a shop, not a war zone.

Also a metallurgist, and hammer faces ARE hard enough to chip. As far as exploding, that is a relative term, but the hammer faces can definitely violently chip.

Also saw the MythBusters episode and that was a poor experiment and test. The heat treating process that they used near the end of the show was uncontrolled/sloppy and resulted in the wrong microstructure to cause chipping -- I didn't need to see the end to know that hammers would bend rather than chip. During the test, the heating temperature was too low (some people recommend a magnet to test for proper heat, but that is wrong as well because the nonmagnetic point for steel is about 300 degrees too cold to quench); they walked about 10 yards before they quenched the hammer so they lost even more temperature; they quenched it in oil (probably should have been in a water blast for the hammer steel chemistry); I am assuming that they believed that oil would add some carbon (another wive's tale); and finally, even if they did the heating and quenching right (which they didn't), they removed the hammer from the oil before it would have reached a low enough temperature to form martensite (harden). All in all, a failure.

The real question here is whether to wear eye protection when striking anything with a hammer. The answer is YES. My father practiced ophthalmology for 40+ years in southern Texas, and he had a nasty little rogues' gallery of metal fragments he had removed from the eyes of patients. He was adamant about eye protection, having treated several patients who eventually lost part or all of their sight due to foreign-body injury. Dad was proud to have initiated a policy at one of the local plants, requiring all personnel to wear safety glasses while on the plant grounds.

Steel is Steel. If you look up what the hardness is on a typical claw hammer, you'll find it to be Rockwell 50-60. A ball peen hammer may be hardened to 57R. Brick chisels are hardened to 60-61R. What do you hit a brick chisel with? A driving or mash hammer (also hardened to 57R). So what is the difference? I saw the Mythbusters program and they went far beyond the typical tapping. (typical, but that's what Mythbusters does.) You should always wear safety goggles when hitting steel, but unless the hammer is defective, I don't see any difference in using the hammer instead of a drift, but my preference would be to use the correct tool. (the drift)

I worked at Stanley Tools on the team that developed induction heat treating for hammers. First, the heat treating is not simple. and second, hammer heads can spall (chip off). Particularly hammer head repeated banged together! We did high speed camera pictures and found that repeated hitting head on head did cause cracks to occur and eventually pieces did fly off. Striking hammer to hammer was once common practice when attaching wire to fence posts. The induction heat treating largely eliminated the problem but NEVER bang hammer faces together. EVER! Mythtbusters not withstanding.

Years ago I was working on a roof and used a hammer to drive another hammer under a spike. My good hammer was a estwing ripping hammer ($20.00)and the second was a claw hammer with a fibre gras handle (4.00). After a couple of serious blows a frament of the cheap hammer broke off and imbedded itself in my chest. Fortunately it didn't get much deeper that the skin. this is the last time i did this and also the last time I picked up a cheap hammer.

One chilly morning 30 years ago, I was stripping concrete forms by using a hammer head hatchet & hitting the hammer end with a big ball peen hammer. First good whack of the day (you know - tap, tap to set it and then whack) the mallet part of the hatchet flew apart & 'lost' about 1/3 of it's hammer face; enough metal to make maybe 23¢ in change. Dunno where it all went but a peanut-half sized chunk went deep into my hand / thumb joint and had to be removed by a doctor.

Explode with lethal force? To be fair, it didn't truly explode but I'd say that had that chunk hit someone in just the right spot it certainly could have been lethal. I still work in the contracting / woodworking biz and I never, ever hit hammers together.

Seems I'm one of many to respond. I was using two hammers to pry nails out of a roof. After repeated striking of the heads together one of the heads shattered sending a chunk right into my glasses. It left a scratch in the lens. Good thing I have poor eyesight or I might have lost a eye! Myth Confirmed!

My issue is with MythBusters process. They do not use a scientific method. They minimally need a control group and a test group for each different test they are doing. ... If they did it 'right', and boil results down to numbers and graphs, etc, it wouldn't be as glitzy and in your face as their program is.

I consider whatever results I get from them as additional anecdotal evidence, not a real study.

Their program is entertainment first, information obtained from them is just what you see. And it is not rigorous in considering real world, long term use, covering all options availabe, or a hardcore scientific study.

Enjoy their program, but just consider it entertainment, not more, not less. And yes, I enjoy seeing their stuff too, just like I enjoy the Dirty Jobs show.

I am a person who has been in the Building and plumbing indystry for 47 years. I also was raised on a farm.

with this experience I have not only seen this chipping happen when I was young I learned abouy this the hard way.

These hardened surfaces are brittle and if they are impacted at the right angle they will chip. I have seen one shatter, trust me on this is is no fun to see that happen.

Seth ( the old plumber)

First, in the example, it seems to me that you could use a center punck or something intended for such use, held against the miter gauge instead of a ball peen hammer.

Second, another poster said that a brick chisel is hardened steel and no one was ever hurt by a shattering brick chisel. True, but as far as I know, only the edge of the brick chisel is hardened--the striking surface is not. Even so, chisels that have "mushroomed" have been know to have pieces fly off when struck. I guess the moral of the story is to at least always wear safety glasses.

It looks like we pretty much agree, scientific testing or not, that hitting hammers together isn't a great idea. What concerned me in the first place is the picture showing a table saw being used as an anvil.

I am a shop teacher of 31 years. Fracturing hammers is no myth. I knew better; but used two hammers in conjunction with each other to straighten a bent truck rim that came in contact with a curve. They worked fine to fix the rim but I have a chunk of metal buried in my left thigh to prove hammer heads due in deed fracture when they impact each other. I was fortunate it did not strike an artery or my eyes. Needless to say,I will never try this again.

At the risk of sounding like a smart - - - , my contribution to this debate is: JUST DON'T DO IT! There are other less controversial and conceivably less unsafe objects with which to hit the ball peen hammer.

I think a lot of commenters are missing the point of the Myth Buster episode. The episode responded to a belief that a hammer would "shatter" when struck by another hammer. In their tests, the hammer did not "shatter." Nobody doubts that hammers may chip, and that such chips can be dangerous. Even Myth Busters constantly repeats the mantra, "wear safety glasses!"

When I was a kid my dad would take me on his second job occasionally, carpenter, it's what origionally spurred my woodworking interest. We were 1 time working on the roofe of a persons shed out behind their home and dad was taking shingles off by using 1 claw hammer and hooking the claw under difficult nails and striking the head of that hammer with the second hammer. That was abou 45 years ago and I remember the bright red bursting of blood when the shrapnal from the hammer head fracture flew into his forearm so fast I couldn't see it travel, it was like a bullet. The doctor couldn't find it and he carried that tiny piece of artery peircing metal in his arm till the day he died. My brother still has that hammer even with the same handle on it that dad used all those many years ago but you can clearly see the chip where the fragment came from and the face of the hammer is peeling line the scales of a snake.. DON'T DO IT Mythebusters were wrong.

Safety is always foremost in our mind at FWW. But here's the point people are missing, and the reason we allowed that photo to run in the first place. The force needed to peen the corner of a miter-gauge bar is very slight, and two hammer faces are not going to shatter from light taps. So the safety police are right in theory (there are situations where one hardened face could splinter another) but wrong in this specific case. The context makes all the difference.

This reminds me a lot of the letters we get each time we run a photo of someone grinding on the side of the wheel. Grinding should be done with a light touch, and there just isn't any danger of the wheel exploding as some warn. Yet the letters pour in, saying, "I was always taught..."

I went to tech school for high school and worked in machine shops, and saw people use the side of the wheel regularly and safely, but with a light touch, of course. The edge of the wheel is where you should do most of your grinding, but there are times when the flat side comes in handy.

An old mason told me the way to buy a hammer was to take 2 and tap together. If there is a ring one has a flaw and will eventually chip and break. Keep testing this way until neither rings and you will have a good hammer in either hand. The hammers I bought using this method are still intact and have not chipped. So I agree it not a good idea to deliberately try to break a hammer, but it comes with the territory. People need to realize that if you hit metal on metal enough times something is going to break off. If you are lucky it won't cause injury, but to be forever injury free means you are wrapped in bubble wrap and do nothing but drink liquids from a rubber straw. Otherwise you have to live life and take your chances and take responsibility for your mistakes. Lawyers are for the justice system not for paying off for stupidity.

I can say for a fact that bad things can happen! While trying to pry off some window moulding, I struck one hammer head on another to drive the claw under the wood. A chip came off and lodged in my wrist, near a nerve and had to be removed by a surgeon. The same is true of sledge and wedge, even though the wedge is softer. a chip the size of a .38 bullet came off and tore my femoral, creating a real mess and scaring my wife to death! Spent the night in the hospital!

Just don't do it!

In my experience, hammers do chip. I carried a triangular shapped hammer chip in my 1st finger for over 5 years. The chip flu like a bullet and I did not see it in my finger. The hammer was being used to pound on a tent stake. To claim that light taps on a hammer with another hardened hammer will not cause a chip is false. I have worked in manufacturing for years and to assume everything is made within the correct tolerances for hardness is false. An improperly heat-treated hammer can chip with a light blow. There is too much stuff being recalled now days to assume manufactures are going to spend the extra time and money to make a product that will perform as expected without some chance for a serious side affect.

Why not use a wood mallet on the hard hammer if you need to make a light tap?

I think that this might take the cake for the most assinine discussion to date on FWW. I am beginning to wonder whether many readers/ subscribers ever take time away from Monday morning quarterbacking and second guessing everything to actually get in the shop and build anything. My suggestion in this: use common sense, try to apply it to whatever you may read, and go build something. I think we can all agree that banging a 16 lb sledge around probably isn't a good idea, but I think I'll keep my glasses on and take my chances tapping a couple of ball peen hammers..

Hope your hairsplitting and griping goes well; I think I'm headed back to the shop.

Re striking hammers.

A lesson I took to heart 60 + years ago when a friend's older brother hit two, what I learned later were framing hammers, together, He sported an inverted teardrop for the pupil in his left eye. A piece fractured off and cut the Irus. Fortunately it didn't blind him. So even if rare why temp fate. Why not stand beneath a tree during a lightening storm if strikes are really rare? Because of the 'image' I, to this day, do not strike hardened surface on purpose. Being a retired mechanical engineer suggests not to. I keep two ball peen hammers for striking metal.

Conme on guys what if the vibration of the hammers striking causes that shelf to collapse on your head. Wear good eye protection!!!! Do we need to walk around with protective suits to guard against everything? Of all the dangerous things I have done in my shop hitting 2 hammers together isn't even on the list.

I, too have had chips fly off two hammers struck together. Fortunately, I nor anyone around me was injured. Beside, a better way to "dimple" the miter guage slide would be to use a an old nail set.

I still have a chunk of hammer in my left shoulder. Lucky it was not somewhere else.

I agree with Beckum... use brass.

Several years ago I needed an MRI to diagnose a torn Meniscus. I encountered EXTREME pain when the metal chip I was unaware of started flying around the inside of my knee.

Looking back as to when the chip in my knee first occurred was probably in the early sixties when I was in metal shop in school and hammering metal on an anvil. I recall the hammer had chipped and had hit my knee. I didn't realize the blood on my knee indicated the chip had embedded itself in my knee.

There was probably nothing I could have done to prevent the injury. But to say this doesn't ever happen is folly. I can only imagine what would nave been the outcome if the chip had embedded itself in my eye.

Striking one hardened surface against another is patently risky. The steel may not "shatter" ( an absurd notion unless it's frozen to cryogenic temperature) but it will shatter in small locales, and send sharp, dangerous shards flying. It will, it does, and there are a lot of one-eyed unfortunates who learned it the hard way. I am frankly dumbfounded that any engineer might have espoused such a test and claimed the prohibition to be myth, thus risking the vision of countless trusting listeners or readers.

The trick is always to use a hammer against a softer material. In this case, a hammer and center punch would have been appropriate. Needless to say, using any hammer or similarly violent tool without eye protection is foolhardy, no matter how light the blows. Stand beside the tiger long enough, and he'll eventually invite you to lunch...

It is not safe to claim that "I was only going to hit it a few times, and not with much force." Hardened steel against hardened steel is dangerous in any striking situation.

Striking purpose-built steel tools together is an investment in faith in the manufacturer, because all steels are not equal, and the differences are not detectable to the unaided eye. Tool manufacturers operate within strict tolerances for metal composition, strength, hardness, grain size and orientation, etc. so as to ensure that striking surfaces are compatible with one another among purpose-designed tools. For example, a center punch may have its tip tempered to extreme hardness, but feature softer steel at its striking surface. Similarly so for wood chisels, plane blades, etc.

If the user has so little sense as to "abuse the system", the tiger heads home for lunch.

Cheap hammers nearly always come from countries and manufacturers who profit from "looks like" tools aimed at amateurs who don't know the necessary details. For myself, I never purchase a steel-head hammer not manufactured in the U.S., England, or Germany by a reputable, time-proven manufacturer.

Incidentally, there are two rows of center punch marks down each side of my miter square's bar, which I struck and then filed to perfect fit over 25 years ago. The effort is lasting, and well worth the time to perform properly. My daily user is a newer Incra with screwed buttons for slide clearance adjustment.

Sorry to write twice - the contact page does not acknowledge receipt of message, which may be important to some readers. Message to Taunton:

On this web page, https://www.finewoodworking.com/item/17562/reader-says-mythbusters-missed-on-hammer-strikes , you feature a photo of some misbegotten soul striking the upper surface of a miter gauge bar.

That surface must NOT be abused, lest it project above the table surface or bow the bar out-of-flat. The subject concerns improving fit in the slide, which requires work on the SIDES of the miter bar.

You've shaken my faith with this error.

I have been a safety and IH professional in the construction field for over 35 years. I have only seen a chip from a hammer striking another case hardened surface, do damage one time. In that instance a friend of mine lost an eye. (Yes, mom was right, you can lose and eye) If you play the odds, it is not likely to happen to you. My only question to you at that point is: What if you don't beat the odds. My friend has been without his eye for over 25 years. Think your eye is worth challenging the odds? Only suckers bet against the house.

I work as a sheriff's deputy in Wisconsin. One day we reponded to a death in our county. It was a younger male that was working in his shop. The death was suspicious until they removed his clothing and found a small wound in the chest area. It was found that he was striking two hardened surfaces together(Hammers) and one chipped. The chip entered the chest cavity and lodged into his heart, cuasing him to bleed out internally. Other than that little hole, there was no other trauma. That solved the debate for me. When they say it could result in death they mean it.

Mythbusters were silly. Ask any ophthalmologist (eye surgeon)about the destroyed eyes they have seen from flying metal pieces (as I have). Don't depend entirely on safety glasses alone, as pieces can enter the eyeball from above and below the glasses. The safest way is to use face shields like wood turners use when striking metal on metal.

John Watters - been there and seen it

Obviously there is always a risk, which is unacceptable in my mind, when striking one hardened steel object against another.

The danger arises from the physics of the strike. The least amount of danger (since we're talking about moderate blows) occurs when the two faces are perfectly flat and strike each other as perfectly parallel hammer faces.

The rub is perfectly flat and perfectly parallel. What hammer face is perfectly flat (let alone two)? And as we know (think floor loading calculations or pushing a chisel through), the force is multiplied as the contact area is reduced. One hammer slightly askew is all it takes to multiply the moderate striking force into a great amount of force at the place of contact.

My verdict? Don't risk it.

When I first saw this topic in Fine Woodworking I was tempted to air my experience, but 'lazy' won out.

Now, I would like to add my comments to the 'Hammer Strike' debate.

Whwn I was just going-into-teenager my father worked for a local hauling company, driving large trucks. The money wasn't all that great and so he took advantage of any opportunity to scrounge things that would have been wasted. One of the things he brought home was rough 2x6 and 2x8 lumber that had braced new vehicles in the railroad cars to prevent their moving about. Many of the boards were strapped at the ends to others, held in by spikes. After getting them home it was a job removing the metal strapping & the spikes. One of the ways to remove the spikes was to drive the claws of a hammer under the head of the spikes to get that initial purchase.

I was doing this one day using 2 clawhammers. striking them face to face, when I recieved a rather severe eye injury. I though at first that an end of the strap had flicked up & hit me, but after waiting 3 days in the hallways of the local hospital after x-rays, I was sent to the University of Alberta Hospital where more expert medical was available.

They saw that there was a chip of metal embedded in my retina, and tried to do something about removing it, but the pressure in the injured eye was so great they couldn't penetrate into the eye itself. Considering that this was in the fall of 1957, I was probably lucky they didn't remove the eye.

So I was left with a chunk of steel embedded in my retina for many years. In about 1990 my GP wanted an x-ray of my sinuses because I had several bouts of an infection. When he saw the bright white spot on the x-ray he immediately wanted to see me. After explaining what and why it was, he ordered some sophistocated tests, as the iron leaching into the interior fluid would eventually destroy the retina's capability. Five years later the same tests revealed that there was a noticeable deterioration in the retina's capability, so he sent me to a eye specialist to arrange the surgery. At the same time, that eye was devloping a cataract, so another surgeon joined the fray & both were done at the same time.

The metal chunk had embedded itself in the retina, severing the nerve to about %40 of my vision. The chunk broke up into several particles as she tried to grab it, so she ended up suctioning out a lot of the fluid to get it all, more than half of it. I then had the curious sensation of watching my eye refill itself over about 2 months or so. Only after the level reached above the pupil could I see objects with any clarity.

I still have that chunk of hammer. It was about 0.5mm by 0.3mm by about 0.1mm thick. It had gone completely through the lower white of my eye, through all the gel/fluid in the interior and had lodged itself in the retina at the back of the eye, severing a lot of nerves. It missed the main optic nerve 'bundle' in that eye by about 5mm.

I have always wondered what it's actual velocity was.

dsparks

I have never tested the hammer/hammer no-no.... why tempt fate or one's health???? However, having heated with wood for over thirty years and splitting by hand for the first fifteen or so, I can attest to the frequency of metal chips suddenly launching from the surfaces of wedges, splitting mauls, and sledge hammers which by the way sound exactly like bullets whizzing by. I have only been the victim once with a piece of metal lodging in my leg. On another occasion while dressing rocks with a small sledge hammer and a metal chisel in the lower meadow that were causing problems with my mower while cutting hay, a fragment of the chisel lodged under the skin of my hand above the thumb. The cut through the glove was surgical as was the entry wound in my hand. No matter how careful you are... stuff happens so be aware of the possibilities and don't take unnecessary chances.

I am a retired metallurgical engineer with a lot of failure analysis experience. Those are my credentials for adding the following comment.

There are a lot of valid comments about chips flying off the faces of hammers (and other heat-treated tools) in this string of postings. The technical reason for this is that high impact can cause some of the steel in the tool to transform to "martensite", which is the hardest and most brittle form of steel. When you heat treat a tool to make it hard, you first quench it from an elevated temperature to transform all (or most) of the steel to martensite. In that condition it is hard, but it is too brittle to be useful. The next step is to heat the tool to a moderately high temperature to transform the martensite into something called "tempered martensite". The higher the tempering temperature, the lower the hardness and the less brittle the steel. OK, that's the end of the lecture - but I'll be happy to answer questions about steel heat treatment from interested folks.

The key is that hitting a hammer can transform some of the head to brittle martensite, and that is where the danger lies. The next time you hit that spot a chip can break off - as was well attested in precious comments. Probably the most common occurrence is with wood-splitting wedges. They get pounded hard all the time, and they often produce flying chips. Always check your wedge heads before use and grind off any split or cracked areas.

Having said all that, I really doubt that hitting a ball=peen hammer to dimple a miter bar is going to cause a flying chip UNLESS the hammer head already has some martensite from previous abuse. It is just not a hard enough blow. Just be sure to check your hammer heads frequently for chipping and cracking and grind off the chipped area or get a new hammer.

Len Dorsett

Edwin,

When a cow pook was asked "How close can you get to a rattle snake without getting bit?" He answered " Don't know how close but know I'll stay as far away from it as I can get!" Same goes for hitting two hardened metals, or hammers together! Make it a hard and fast rule---don't.

Anybody with these reports of dire happenings wearing safety glasses or just spectacles? If you break up concrete with a sledge hammer would you wear safety glasses or conclude that one shouldn't break up concrete with a sledge hammer in the first place? C'mon guys, suggesting that nobody is going to drive the claws of a claw hammer under a spike with another claw hammer is living in a dream world. Wear eye protection and get to work.

Sincerely,

Robert H. Galloway

l have a scar above my left eyebrow from doing this, l was wearing safety glasses and the piece of steel hit me just above the lenses and stuck into my skin, not just like a sliver or something it was in there good! lt was a very small piece(about the size of a sesame seed) but l am sure if it had hit me in the eye l would have done some damage without question. the face of the chipped hammer hardly had a mark in it and if the piece had not hit me in the face l probably would not have noticed, just a mark on the side. the odds of getting a hammer to ''explode'' is probably very very small, but just a glancing blow can easily knock off a very small piece at almost the same speed as a bullet.

By training I am an avionics technician and an aviation electrician. Basically if it has electricity involved in it on an airplane, I used to work on it. I am also a redneck that has been living on a farm for 30+ years. I used to watch Mythbusters until I realized, they just don't get it. The bust what they think is the myth, and many times are very wide of the real point.

In my working life I have come to a simple conclusion. When one hard object hits another hard object, there is ALWAYS a chance for chips to fly. I don't care if an engineer tells me its impossible, I have seen to many impossible things happen. Luckily I have never injured myself, but I have seen some one eyed people that are shy one eye because of something hard flying.

This leads me to the inevitable conclusion that chips can and do fly from hardened objects when hit by another hardened object. Is this going to keep me from doing it? Nope! Sometimes it is just the best way to do something. But being a smart Redneck, I am sure going to be careful when I do it. I use eye protection, leather gloves, heavy pants and shirt.

Look at it this way, the new sawstop table saws can stop a saw blade without damaging a hot dog. But does that mean you are going to stick your hand into it to test it? I won't. I am still going to practice good safety. Doesn't matter if its two hammers, or a table saw. Remember, all it takes is one error, and all your friends will be calling you lefty, or patch, or one eye, or something equally moronic.

About the original myth, remember Murphy's law. Remember the crash of United Airlines Flight 232 at Souix City. That was caused by a microscopic bubble in a rotor. If someone can think of an accident, I can guarantee that eventually it will happen. Might not happen to you, but it will happen to someone.

Be safe!

My boss lost an eye to a small shard coming off one of two hammer heads (you had to feel it to see where it came off the edge). Mythbusters is confirmed entertainment, but marginally plausible science - though to their credit they try. They need a science consultant (or a better one). Also have a good friend who was involved in burning down an aircraft hanger due to improper disposal of linseed oiled rags. Probably why I'm so paranoid in the shop! :)

My boss lost an eye to a small shard coming off one of two hammer heads (you had to feel it to see where it came off the edge). Mythbusters is confirmed entertainment, but marginally plausible science - though to their credit they try. They need a science consultant (or a better one). Also have a good friend who was involved in burning down an aircraft hanger due to improper disposal of linseed oiled rags. Probably why I'm so paranoid in the shop! :)

Mythbusters may be full of it but the girl is cute.

I have seen "Mythbusters" on several occasions. Once in a while the're right, but as danhoover wrote, far from the point.

They said a bullet fired straight into the air couldn't hurt anybody, yet the same show interviewd a surgeon that has treated at least one such case.

Will there be chips when two hardened surfaces are struck together? Oh Hell yes! I still have the chunk of chisel in my lower abdomen from striking a hardend bearing race with the chisel with out heating the race to soften it first. There is always the possiblity of chips even when one surface is softer material. When it comes to safety, think 3 or 4 times first.

Speaking as a metallurgist, hammers that have been forged and heat treated (tempered) properly are likely not to chip when hit against one another. A cast hammer is more likely to have porosity and although tempering may help retard chipping, I would not hit them together.

We should all remember that Mythbusters is entertainment, not science.

I too have been hit in the cheek by a chip coming off a claw hammer being struck by another claw hammer trying to get purchase on a nail. No damage, but a good warning.

Thanks, Dulcimers (Len Dorsett) for the explanation. Now I know why my splitting wedge, and cold chisels behave the way they do. I have always ground off the fractured bits, but it was to keep them from shredding my gloves. Now I have a better reason.

HI all. I'm an optician by trade and as such have seen the results of many eye injuries and hammer chips are a good source of these. However Mythbusters was looking to debunk the myth of the "exploding hammer" and this does not exist. Hammers chip and they are very dangerous when struck together, but they do not "explode". The fault here lies in Fine woodworking using this tv show as a defense in this debate about chipping hammers not exploding ones.

While I've never had a steel hammer chip, I've never wailed away on anything while using a steel hammer with enough force to classify the "use" as abuse. I have chipped splitting wedges with a sledge.

On the other hand, I chip stone. I can and have chipped stone all day and know just where each chip will come from and where it will go. The chief lesson learned is that chips are predictable. Any brittle material will chip and the geometry of the strike and striking surfaces, the relative hardness and toughness of the hammer and the object being struck all enter into the result. You would not for instance try to chip glass with a glass impactor.

If you try driving the claws of one hammer under a nail using a another hammer, the plane of the strike interface is going to run through your body, possibly even your head. Since the hammer faces are likely to be nearly equal in the important physical traits (like two pieces of glass or obsidian), either piece may chip. Since the primary degrees of freedom of motion for resulting chip motions are going cluster around the plane between the impacting surfaces; the motion of chips is going to be within a few degrees of that plain. If you can see that point, that's bad. If someone else's body can be intersected by that plane, that's bad. If a surface is present near the blow and and could serve to cause ricochets, that is not good either.

Adequate safety precautions are fairly simple. First, never, ever strike two objects of similar composition and physical character together (well lead or copper will probably be OK, but even brass will sometimes crack and chip). Second, wear safety gear. Third, have others clear out of the potential discharge path of resulting chips. Fourth, a backstop should be a material a chip will embed in rather than bounce off. So peen on a piece of plywood on the workbench, NOT on the cast iron saw table.

JDougherty

Why would you stand around and bang hammers together? Sure seems like a dumb idea to me. If you are that bored I've got some sanding for you.

Why hit the ball peen hammer? Just swing it as it was designed to be used. A better way to get the desired results would be to use a center punch along the top edges of the sliding bar. I am not all that impressed with Myth Busters. Some of the methods they use are very questionable at best.

When I was 15 I was using two hammers an a fashion similar to the illustration shown. One splintered and a chard broke off and hit me in the chest. The piece of shrapnel lodged itself in my breastbone barely missing my heart.

When I was a youngster I too struck two hardened surfaces together, a sledgehammer onto an ax, trying to split an ornery piece of firewood. The result was a large razor sharp chip deeply slicing my leg. Myth busters gets this one very wrong. As a result of their false/misleading findings I hope no one tries this very dangerous practice.

OK, this discussion still goes on so I'll add in my story. When I was 12 years old I built my first tree-house. At the end of one workday I was walking up the driveway to my house in Atlanta carrying 2 hammers and banging the heads together in a typically vigorous 12 year old way. Suddenly a searing pain erupted in my left pointer finger knuckle as a hot piece of hammer-head shrapnel flew into my hand. It took my mother about one excruciating hour to dig the tiny piece out with a straight pin and I carry the scar to this day, 48 years later...cheers.

I have problems agreeing with the myth busters. I have been working with hand tools (including hammers, chisels, and punches) for over 40 years and have had several hardened items chip or fly apart when being struck.I worked in a heavy equipment repair facility and we commonly used two 16 pound sledge hammers to free frozen gears or items pressed together with up to 200 tons of pressure. One hammer was held on the frozen part and then struck with the second hammer. Not only have i seen chips fly out from the hardened surfaces of either hammer, but more importantly numerous hammer handles came loose due to the hole in the hammer head being deformed when struck by another hammer.

At one time I was a sheet metal worker using a "tin smith" hammer to hit the head of an other hammer. While hitting it I felt a sharp pain in my left thumb, with a small bloody hole in the skin, I could not find anything in the hole. Two weeks later an ER doctor cut a 1/8" shard of hammer head out of my left thumb joint. The thumb joint on the left is still stiffer than the one on the right hand. Thank goodness that it was not someones eye that was in the way.

I too can attest to Myth Buster’s fallacy about striking two hammers together will not exploded. About fifty years ago, when I was just a little Munchkin, I “needed” to hammer, the separated, head of a ripping hammer into the ground. (Why? Don’t ask, I guess I needed to learn not to strike hammer heads together.) my final strike caused the hammer head to EXPLODE, leaving a marble size pellet missing from the hammer head and a corresponding hole in my leather apron, my denim jeans and my kneecap. Maybe Myth Buster should redefine what they mean by “Explode”. Shrapnel is still shrapnel.

50+ years ago my father caught me hitting one claw hammer with another as I attempted get the claw under a nail head. It was then that I learned that he had no sight in his left eye, having lost his vision when struck in the eye by a chip from one of two hammers he was incorrectly using. Needless to say, I have never forgotten tha lesson.

Just tmy two cents.

If you look at our world of solids, as liquids in suspension, and metal is. We host it's "hardness, toughness, durability" through the tool's existence, in it's lifetime or our lifetime. Every time a hammer is struck, work hardening is incurred. What it strikes, with what force, and what frequency will determine an outcome i.e., two similarly Alloyed metals are struck, likely of similar harness, one will yield to the other, either "denting" or "flaking". It is not to say that a proven three generation hammer will one day reveal a flaw, as you are working, but to to smash your two favorite tools together will push the envelope. The word "flak" popularly (or unpopular) known to WW2 pilots, are metal flakes generated by hardened metals forced together by explosive force. Soft metal under force sprays, hard metal flakes. We are in a period economic and high quality tool production down-turn, less of our metal, do we know or understand, it's linage is far less regulated, respect what you have, and always wear safety protection.

PS The Hardness of a tool is generally set in the final "strike" in the factory, that creates it's final shape. This is why drop-forged hammers are superior, But, this is more of the story.

Mythbusters demonstrated that their hammers, presumably high quality, defect-free hammers, don't chip or explode under normal and even excessive conditions. However, steel can contain impurities, or have problems during various annealing or tempering processes, that greatly increase the brittleness. The point of their experiment shouldn't have been to test whether quality hammers could be made to shatter, it should have been to pre-select known flawed/brittle hammers and test just how bad the shattering could be.

As is pointed out time and time again, why take the chance by testing your own hammer by banging it? Here's a recent event where steel shattered, and even certified safety glasses weren't enough to protect his eye:

http://machinedesign.com/article/inadequate-safety-glasses-no-miner-factor-in-injury-0810

let me start off with a note to Robert Geers, you aswell as the myth busters are correct. but in your own ways and i must agree with robert however. it is a very dangerous practice striking 2 hammers together yes chips will fly if slightly edgedand yes the chips of metal will fly anywhere they want which is usually in the worst places (your eye) and even with safety glasses on they can make it past and cause serious injury. a former employee of my and long time family friend had a regular practice of striking one claw hammer to another to gouge in removing nails until he had the misfortune to chip one, and ofcoarse the metal sliver went straight in hiw eyes lodged itself beside the pupil and a few days later began really hurting him. afterwards went to see an eye specialist. to make a long story short he lost the us of one eye cause of that and yes he was wearing safety glasses. after that i did my own tests with several hammers and a hilti dx450 ramset, i did a dry strike to the sid and head of several different hammer and NO none of them exploded or shattered however after several hit to one particular hammer seemed to weaken the steel and started to chip away. so maybe it wont happen rite away but it will eventually and thats where the danger stands...

Ian

5 days ago I was splitting firewood.I had two mauls (axe on one end sledge hammer on the other)I slammed the first maul into the log to split it but it just got stuck.I picked up the second maul and with the sledgehammer side down slammed it into the sledgehammer side of the stuck maul.I felt the impact about 2 1/2 inches below the tip of my chin right on my larynx (Adam's apple) as I clutched my throat where I felt the impact

blood was spurting out 1/2 inch below the tip of my chin

where a 25 caliber size piece of razor sharp shrapnel entered

my neck.The Urgent Care facility I was driven to said it was to deep in my neck for them to attempt and extraction. I would have to go to a surgeon that specializes in ear,nose and throat surgeries.

So here I am with a severely bruised neck down to my chest and getting worse by the day.So I would have to disagree with MythBusters if they found no danger in the practice of hitting hardened steel to hardened steel.I knew it was a stupid thing to do as I did it.but I did it anyway.I thought the odds of something terrible happening were small but it happened and now I have to deal with the consequences.

Thank you for taking the time to read this I hope it may save somebody from the pain I am going through.

Patrick Burnworth

[email protected]

Hammers do chip and the chip flies with a great force.

I was sixteen building a project with 2 x 4 lumber pounding 16 penny nails with my dad's old (10 plus years old) Estwing framing hammer. I felt a small poke just above my belly button. I lifted up my t shirt and discovered a 3/16 " wide puncture bleeding.

I pulled out a piece of the hammer's head, a 3/16" round chip, that was embedded, but able to be pulled out with my fingers

Log in or create an account to post a comment.

Sign up Log in