Q:

I want to see if the tables of my jointer are within the manufacturer’s specifications for flatness, but I’m confused about how to do it.

Thompson Callahan, Las Vegas, NV

A:

Flatness isn’t the only important thing. To work correctly, the tables must also be parallel to one another.

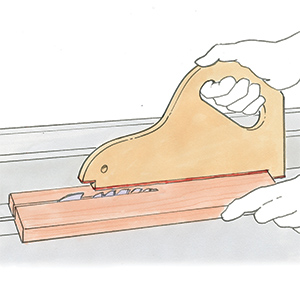

To check for flatness, use a straightedge and a set of feeler gauges. Place the straightedge lengthwise along each edge and down the middle of both tables. If there is a gap of more than 0.005 in. over a large area, you’ll need to return the table to the manufacturer, or have it reground by a machine shop.

Now set the straightedge on the outfeed table with at least 2 ft. extending over the infeed table. Raise the infeed table until it just touches the straightedge. If the tables are parallel, there won’t be any gaps. If not, you’ll have to shim the ways. See FWW #142, p. 41 (Joiner Tune Up) for more on that.

|

|

Fine Woodworking Recommended Products

Bessey EKH Trigger Clamps

Grizzly G0495X Industrial Helical Cutterhead 8-in. Jointer

Rockler Dust Right 650 CFM

Check for flatness first.

Check for flatness first.

Log in or create an account to post a comment.

Sign up Log in