Fine Drawers Without Dovetails

Pinned rabbets are attractive, durable, and much easier to make than hand-cut dovetails.

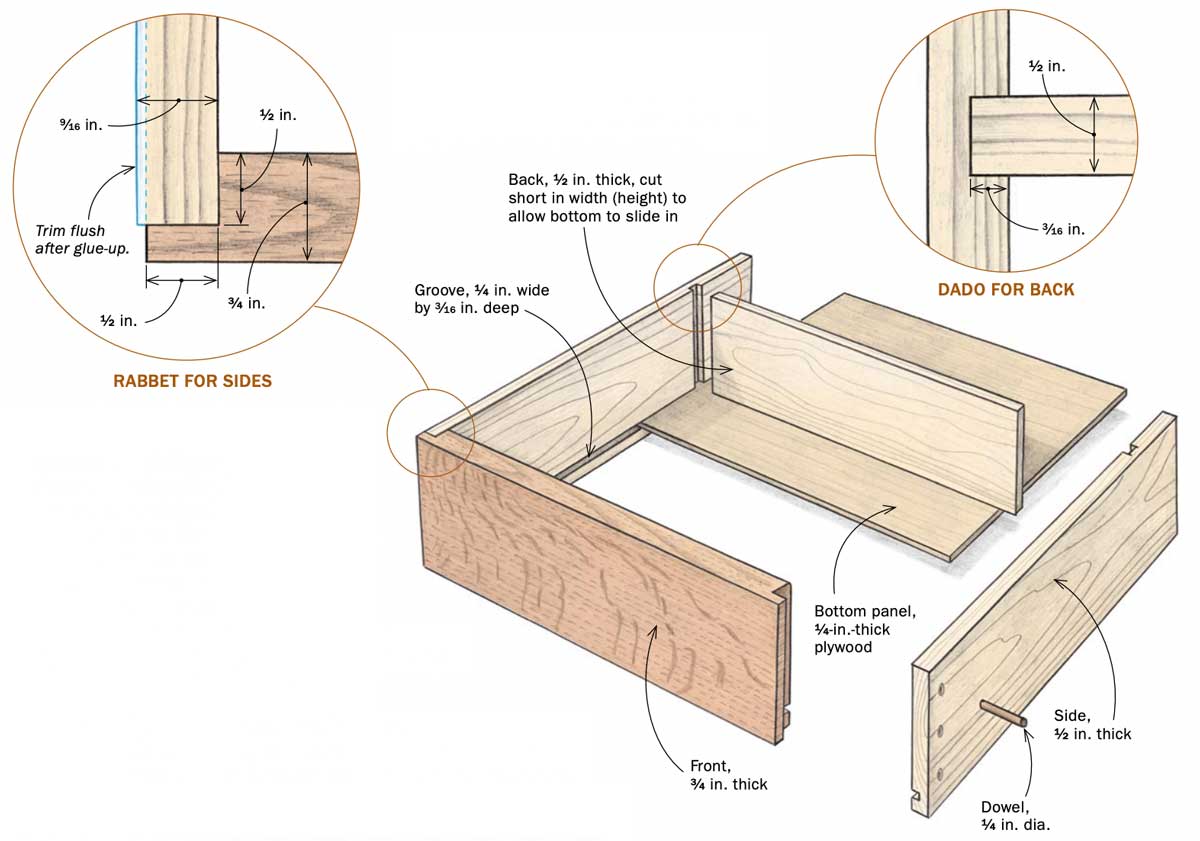

Synopsis: Pinned rabbet joints are a strong and beautiful alternative to the traditional favorite of woodworkers–the hand-cut dovetail. This method of building a drawer is a staple in Hendrik Varju’s repertoire and his customers love it. The anatomy is simple: The front joint is a rabbet, the back is a dado, and the drawer bottom rides in a groove. The pins go in after the drawer has been glued up. All of the joinery is cut quickly and easily on the tablesaw.

Beautiful and strong, hand-cut dovetails are the favorite drawer joint of many woodworkers. And because of the skill needed to cut them well, they are considered a hallmark of craftsmanship. But they take a lot of time to make and even more to master. If you’re not a slave to tradition, there are other joints nearly as strong and beautiful that can be made in a fraction of the time.

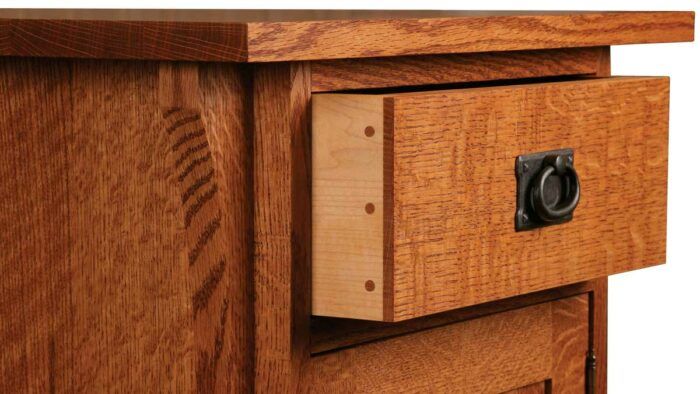

In my experience, the best alternative is a drawer with pinned rabbets at the front, and dadoes to hold the back in place. All of the joinery is cut quickly and easily at the tablesaw. My customers—who aren’t biased toward dovetails the way woodworkers are—have never complained. In fact, they find the clean, crisp lines attractive and comment that the drawer doesn’t look mass-produced.

I’ll show you how to make the drawer with a 3⁄4-in.-thick front, 1⁄2-in.-thick sides and back, and 1⁄4-in.-thick bottom, but the same techniques can be used to make smaller or larger drawers.

Simple anatomyThe front joint is a rabbet, the back is a dado, and the bottom rides in a groove. The pins go in after the drawer has been glued up. |

Making parts in the right order ensures tight joints

To make these joints strong and gap-free, cut the rabbets and dadoes first, and then mill the parts to fit them. If possible, make the parts from quartersawn lumber, which is more stable than flatsawn. The joints will be stronger and the drawer will fit better through the seasons because the parts will move less.

Plane the front to thickness and cut it to length, but keep it 1⁄16 in. over the final width (height). Cut the sides to final length and width, leaving them a bit thicker than needed; they will be trimmed to final thickness after the drawer has been glued together. You’ll fit the back to the drawer as you make it, so leave it oversize for now.

Use a sacrificial fence to cut rabbets

I cut the rabbets on the drawer front with a dado set stacked wider than the rabbet, burying the extra width in a sacrificial fence. Dado cutters are designed so that the outer blade cuts slightly deeper than the chippers to help prevent tearout. It’s barely noticeable on the inside of the rabbet but it creates a gap on the outside of the rabbet after the joint is glued. Burying the cutter in a sacrificial fence eliminates the gap.

Mark the rabbet on one end of the front. Set the blade low, make a test cut, and raise the blade a bit. Make a second cut and repeat until the cutter reaches the layout line. Then cut the rabbet on the opposite end.

Fast tablesaw joineryA tablesaw makes quick work of the rabbets, dadoes, and grooves. And the saw’s accuracy translates into tight-fitting joints.    |

Extralong sides let drawer open all the way

After the rabbets have been cut, it’s time to cut dadoes in the sides to hold the back. I locate them 2 in. from the back, which creates an extension that lets you open the drawer completely without it falling out of the pocket. Before you cut the dadoes, orient the grain in the sides so you can plane the outside cleanly from front to back. This way, when you’re bringing the sides down to their finished thickness, you won’t blow out the end grain on the drawer front and you’ll get no tearout on the sides.

Stack the cutter for a 1⁄2-in.-wide dado. I adjust the depth as I make test cuts, just like I did with the rabbets, until I reach 3⁄16 in. To reduce tearout, I use a miter gauge with a backer fence. To locate the dadoes accurately in each side, you can use the rip fence as a stop because you aren’t cutting completely through the sides and leaving a cutoff trapped between fence and blade.

From Fine Woodworking #208

From Fine Woodworking #208

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Dubuque Clamp Works Bar Clamps - 4 pack

Jorgensen 6 inch Bar Clamp Set, 4 Pack

Comments

Fine Drawers Without Dovetails PDF won't open.........over?

It opens fine for me.

Nice tips to find drawers without dovetails!

Log in or create an account to post a comment.

Sign up Log in