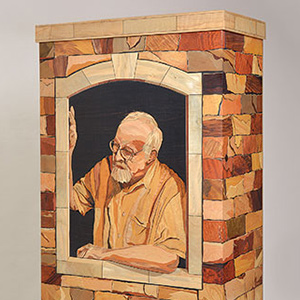

Krenovian Details Make a Big Difference

Add Krenovian details to your next cabinet-on-stand

Synopsis: The handcarved friction catches and strikeplate buttons on a Krenovian piece are far more personal than manufactured door latches or hidden magnets. This master furniture designer liked to add details that are playful to the eye, friendly to the touch, and comfortable to use. Even the shelf supports on Jim Budlong’s Krenov-inspired cabinet-on-stand are done by hand, with care and attention to form as well as function.

In a companion article, read how to build a Krenov-style display cabinet.

From Fine Woodworking #208

One of the features that make Krenov-style cabinets so friendly and special is all of the cool little details. As those familiar with the work of James Krenov know, he had a fondness for shaping small bits of wood with his homemade knives. On this cabinet-on-stand project (see pp. 48-55), I added a number of these special details, including Krenov’s handcarved friction catches paired with strikeplate buttons—far more personal than manufactured door latches or hidden magnets. He also likes handles that are playful to the eye, friendly to the touch, and comfortable to use. Even the shelf supports are done by hand, with care and attention to form as well as function. And like Krenov, I left behind subtle tool marks to remind people that not everything in this crazy world is stamped out of a mold. Try just one or all of these handmade touches. I think you’ll find that Krenov was on to something. As he often said, “It’s the little things that count.”

Friction catches and strike-plate buttons

Friction catches are small pieces of wood (with a cam shaped on the front end) let into ramped mortises on the underside of the cabinet top with a spring behind them. The strike-plate buttons are round, and barely protrude from the inside surface of the bottom. The pressure felt from the springs and catches at the top of the doors coupled with the small button-like strike plates underneath the doors provides the user with a unique sensation as the door is operated. The friction catches and buttons don’t need to be made as part of the cabinet-building process, but the mortises for them should be cut before the glue-up. The friction catches are installed perpendicular to the front of the cabinet above the doors, about ¾ in. from each side of center.

Hand-carved supports make elegant shelf holders

Like the friction catches, these small carved shelf supports don’t have to be made during carcase production, but the holes need to be drilled before the carcase is glued up. To make the supports, start with a block of accent wood and use the tip of a Roman ogee bit to profile both ends. Then run the shoulders on the tablesaw using a stop block on a crosscut sled. Rip this chunk on the bandsaw into thin strips (each strip ends up with a roughed-out support on each end), clean them up with a block plane, and refine them by hand.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Sketchup Class

Drafting Tools

Log in or create an account to post a comment.

Sign up Log in