Step Up to Whole-Shop Dust Collection

Rigid ducting is the way to go, especially if you follow these 12 tips.

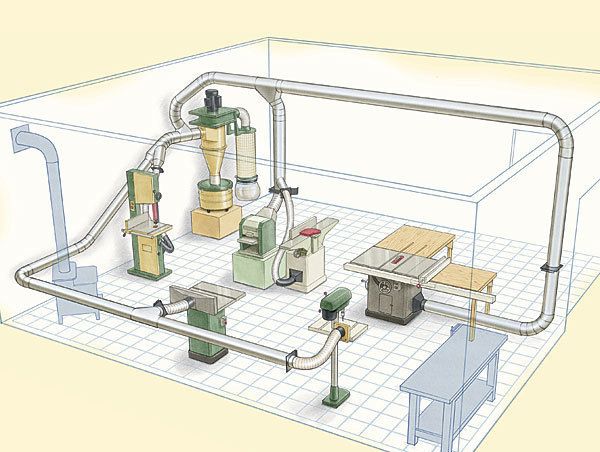

Synopsis: This article offers a number of tips on setting up a rigid-duct system for home woodshops. Large-diameter, smooth-walled rigid ducting generates less friction than flexible corrugated hose and brings powerful suction to every power tool in the shop. Upgrading to a solid-duct system isn’t cheap—adding it to a 600-sq.-ft. shop could cost more than $1,000. And, it might take a few days to put it all together. But when it’s done, you’ll be putting more dust in the collector and less in your lungs.

If you’re like many woodworkers, your dust collector’s duct system is mainly a tangle of 4-in.-dia. flexible hoses leading to the dust-collecting machine. And there’s a good chance you’re not satisfied with either the convenience or the efficiency of the system. You probably have to move and reattach hoses at times, or just live without dust collection on some tools. You might also be clustering tools close together in an awkward array to keep hose runs short, or living with hoses underfoot. Last, with corrugated hose, you are losing a significant amount of suction to friction. Sound familiar? Well, it might be time to upgrade to a rigid-duct system.

This article offers a number of tips on setting up a rigid-duct system for home woodshops. All the tips focus on saving you money while making your system work better. A lot of what I learned about dust collection came from Bill Pentz (www.billpentz.com), an expert on the topic.

Why rigid ductwork?

The effectiveness of your dust collector depends, to a large part, on the volume of air (measured in cubic feet per minute, or cfm) moving through the duct. If the cfm is too low, the dust won’t be carried along effectively. Friction plays a key role. With less friction, you get more cfm and more dust moving toward the collector. That means a given dust collector can support much longer runs of ducting and still deliver high cfm at the end of the line.

Large-diameter, smooth-walled rigid ducting generates less friction than flexible corrugated hose and brings powerful suction to every power tool in the shop. All machines connected to my system with 6-in. duct have airflow volumes in excess of 620 cfm (and velocities greater than 3,200 feet per minute.

Upgrading to a solid-duct system isn’t cheap—adding it to a 600-sq.-ft. shop could cost more than $1,000. Plus, it might take a few days to put it all together. But when it’s done, you’ll be putting more dust in the collector and less in your lungs.

Rigid ducting is not a cure-all, though. If you’ve been getting by with a small dust collector hooked up to a couple of machines, you’ll probably need at least a 2-hp collector to handle the longer runs of rigid ducting.

The basics

1 Minimize the use of flexible hose

Use rigid duct wherever possible. Corrugated flexible hose is cheap and convenient, but those bumpy ridges generate three times more friction than straight rigid duct, reducing cfm.

2 Use snap-lock duct

When it comes to straight runs, snap-lock rigid duct is an effective and economical alternative to solid rigid duct. Also, it’s available in several convenient lengths (2 ft. to 5 ft.) in a variety of diameters (4 in., 5 in., 6 in., 7 in., and 8 in.). A good choice is 26 gauge; duct that’s too thin has been known to collapse from the negative (vacuum) pressure. Unlike solid rigid duct, you must first connect snap-lock duct along its full seam.

|

|

3 Join ductwork with pop rivets

The sharp points of sheet-metal screws extend into the duct and can catch chips and other debris. Pop rivets are just as easy to install, but form a shallow mushroom shape inside the duct that’s less likely to result in a plugged-up line. First drill a hole, then add the rivet.

4 Seal all connections with duct tape

Your cfm will drop if air can be drawn through openings in the duct. Wrap the joints with duct tape to eliminate leaks.

Smarter installation

5 Use the largest-diameter duct compatible with the collector

Ducts of larger diameter produce less friction and allow the system to carry more cfm. That’s because a 6-in.-dia. duct has a cross-sectional area more than double the area of 4-in.-dia. duct. So, to maximize airflow, use the largest-diameter duct the dust collector can accept. In many cases, that means removing the factory-installed “Y” fitting on some dust collectors that reduces the larger single port into two or three smaller ones.

6 Make your own hangers

There are a number of elegant ductwork hangers on the market. Although effective, they add significantly to the cost of a dust-collection system. You can use cheap strap-hangers, but they generally won’t anchor the duct rigidly enough. A better option is to make your own from some 3/4-in.-thick plywood, pipe strap, and a few screws. They securely anchor the duct and cost almost nothing. And they work no matter if the duct runs vertically or horizontally. Use screws to attach them to studs or ceiling joists, and masonry nails to attach them to cinder block.

If you need to bypass obstacles, simply increase the distance from the duct to the wall or ceiling. Also, use the longest available straight lengths of duct (usually 5 ft.), and install a hanger at each pipe joint. That way, you minimize the number of hangers and the number of joints that need to be taped.

7 Minimize the length of duct runs

Keep the duct runs as short as possible. That way, the frictional force on the air running through the duct is kept to a minimum. When friction is reduced, the drop in cfm is reduced, too.

8 Use “Y” connectors for lateral branches

Most systems have one or two main horizontal ducts. Branch ducts, often smaller in diameter, connect the dust-producing machines to the main duct. To join the branches into the main duct, you need a connector. Always use a Y-connector, which joins the ducts at 45°, to minimize friction and allow greater airflow.

9 Minimize the bends and maximize the radius

You’ll need curved sections to direct the duct system up, down, in, and around to get to the various machines. Keep in mind, though, that bends generate a lot of extra friction, causing a bigger drop in airflow than the same length of straight pipe. Indeed, in 4-in.-dia. pipe, two 90° elbows can add as much friction as 12 ft. of straight pipe. So, as you design your system, avoid bends whenever possible. In places where a bend must be added, use one with the largest possible radius. A large radius creates less friction than a smaller one.

10 Add a larger port to machines

Most woodworking machines have 4-in.-dia. dust ports, which will require a reducer to connect to a 5- or 6-in. duct or hose, and that reduces airflow. Whenever possible, replace that port with a larger one. If not, place the reducer as close to the dust-producing machine as possible, which allows the larger-diameter duct to run for a longer distance. For tablesaws of almost any type, consider modifying your machine as described in FWW #145 (“Dust-proof Your Contractor’s Saw”).

Do I need a new power plant?

This chart, based on tests conducted by FWW (“Dust Collection Demystified,” FWW #188), shows how much rigid ducting each size of dust collector can support. It allows for an additional short length of flexible hose and the usual junctions and connectors.

At the machine

11 Blast gates are a must

A good dust-collection system connects to all of the dust-producing machines—your tablesaw, jointer, and thickness planer, for example. If all of those dust ports are left open, you are dividing up the suction among them, and none will work well. That’s why a blast gate at each connection is a must, as it allows you to concentrate all the cfm on the tool you are using. Unless you have a 3-hp or larger collector (which can handle two open ports), you should keep only one blast gate open at a time. Be sure to use “self-cleaning” gates.

12 Connect to everything

Since wood dust was declared a carcinogen, some newer woodworking machines have incorporated better dust-collection chutes and ports. If you’ve got ’em, use ’em. But if you have older machines, you may need to attach a ready-made port, or make one yourself.

Typical system in a real-world shop

Schuh’s shop measures 24 ft. square, a common size for two-car garages. His main dust-producing machines—tablesaw, jointer, thickness planer, shaper, bandsaw—are what you’d find in many small, one-man shops. His layout is typical, too.

There are two basic ways to run ducting: along the walls of the shop or over the top, attached to the ceiling. Schuh’s system is a hybrid of both methods. If you have a similar shop, you might find his setup helpful. If not, there are a number of places to go for design help. Air Handling Systems (www.airhand.com) has excellent online resources for designing your own ductwork, and Oneida Air Systems (www.oneida-air.com) has great advice in a section they call “Shop Plan Design.” These sources, and Penn State Industries (www.pennstateind.com) all offer a wide selection of ductwork as well.

Randall (Toby) Schuh works wood in his Saylorsburg, Pa., shop.

From Fine Woodworking #209. For the full article, download the PDF below:

Fine Woodworking Recommended Products

Hedgehog featherboards

Forrest Woodworker II Blade

Freud Super Dado Saw Blade Set 8" x 5/8" Bore

Log in or create an account to post a comment.

Sign up Log in