Students often come to the Studio and ask how do I get started in woodworking? What tools do I need to get? I try to be honest with them. As hobbies go, woodworking is not that expensive. It’s not more expensive than say aviation. Tell your spouse that for starters. It will sound good.

It is however more expensive than kite flying. A lot more. You will need a lot more tools than flying even an attack kite. I think however that that’s the hook for us. It’s the tools. More than anything else, if you get interested in building stuff, you start out being fascinated with tools. More on that in another blog.

For now, the question remains which tools to buy. The first question I ask back is what type of woodworking will you be doing? If you’re just starting out, the answer will be, I don’t know. So it’s hard to know where to start your buying.

Let me offer this advice. I began to get interested in woodworking by finding an old wooden hand plane. It was a beater, a wooden transitional plane, that I found in the bushes which has never worked from the day I found it. It served a purpose though. It made me think that hey this is a woodworking tool and my dad did woodworking and I could do woodworking if I only knew what to do. That hand plane which I still have in place of prominence near my bench, that hand plane inspired me. It’s important to have near my bench. So buy a tool that inspires you to do good work. Even if you don’t know how to use it yet.

Radial-arm saw?

The first big tool purchase of mine was a radial arm saw. Perhaps the most misguided purchase ever. It could do just about anything including Julienne french fries but it did none of these jobs well. It could crosscut crookedly, rip with great danger, cut molding, drill, plane a board [supposedly]. It was the Ronco knife of woodworking tools and it did none of these jobs very well. I still have it. It still crosscuts boards crookedly and that’s all I ask of it now. Good purchase. It has one job to do in the shop and it does it just fine.

A starter chisel

Here’s what I think you should buy for starters. The first hand tool you should buy is a chisel. If you want to learn to sharpen it, then buy a cheap one and don’t worry if it gets short over time. I don’t care what kind of woodworking you do, you’ll always need a sharp chisel.

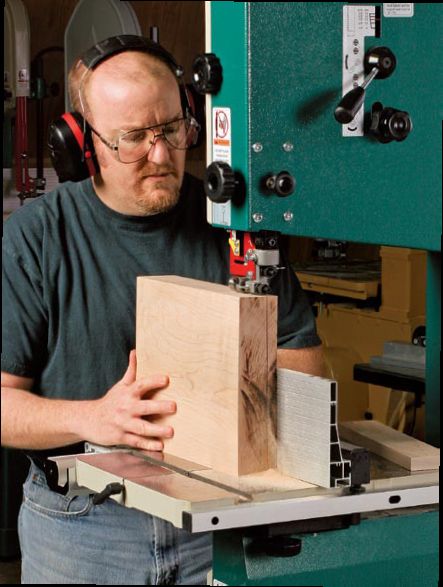

A hefty bandsaw

The first machine I think you should buy is a good band saw. What constitutes a good band saw I leave open to discussion. What do you think is a good band saw? Mine is an old 16″ Yates band saw. When magazines starting writing about blade drift in the ’80’s I kept wondering what they were talking about. I had never adjusted for drift on this saw when resawing. Didn’t need to. It had too much mass keeping things in balance. But those days of cast iron are mostly over. All I know is bigger, when it comes to band saws, is better. Bigger and heavier is better yet. But that’s just my take.

Buy a chisel. Spend a few bucks on it, new or used. Get a good band saw. Spend more than you want to on a good band saw and you’ll only be unhappy once. Then get started on your new hobby. Oh, and buy one tool that inspires you to do good work.

-Gary Rogowski is a Contributing Editor for Fine Woodworking magazine and teaches at The Northwest Woodworking Studio in Portland, Oregon. http://www.northwestwoodworking.com/

Comments

Buy a chisel and then what? It will be a long time before most may actually find a use for that chisel. It will be and even longer time before they find the inclination or earn the money for the grinders, stones and jigs to properly sharpen one. What you mean it wasn't sharp when I bought it?

People usually start through a more direct approach to woodworking using simpler tools to cut 2 x 4s, plywood and drill holes in a wall. As we discover the limitation of the tools and materials at hand we come to explore the possibilities of something better. But it is a long jump from there to needing a 16" cast iron band saw to get started in woodworking.

I think it is humbling to discover how limited were the tools used by our ancestors and skilled craftsmen to get amazing results.

Peter

My first saw was a radial arm saw, true it wasn’t prefect. It used to scare the heck out of me when I ripped long pieces of wood, and then there was the climb cut effect when cross cutting, pulling the blade toward you, it some times stalled out on hardwoods. About 25 year after I bought the thing I got a recall notice from the manufacture, I contacted them and they sent me a box of equipment to upgrade and make it safer. After I installed the stuff I had to push the blade into the wood on cross cuts instead of pulling. Now that makes sense, but why did it take 25 years to come up with a fix? But on the other hand it reduced the size of board I could cross cut. Another feature I thought was cool is that one could convert the machine into an over arm router, the door panels on my first cabinet were shaped on that thing. Looking back it was the only saw I could afford at the time and Sears was the only place in town to buy one, so. Lets face it the radial arm saw had its place in woodworking history and at the time it had all the bells and whistles we thought we needed. So I don’t discount it but look back at the time as the beginning steps of my woodworking evolution. It may have not been the safest and the most accurate saw but I sure did build a lot of things with it. Am I a better woodworker because of it? Maybe, I sure did learn to keep my fingers out of the way of that monster.

Don

A friend recently asked me the same question and my answer was: (1) a good drill; (2) a good circular saw; and (3) clamps. In a beginner's shop, these three things will allow him or her to build almost anything within their relatively limited skill set. If they can afford one more tool, it should be a hand-held router.

Figuring out how to make do with these things will likely prompt them to start building jigs even before they know what a jig is. It will then guide their thinking on what other tools would do the particular job better, and why.

Intarsia and small boxes led to full bedroom sets and tables and even a Maloof inspired rocking chair. My first Delta bandsaw and a small contractors saw was all I needed. It was a great learning curve and I enjoyed every moment since then.

Gary took the words right out of my mouth. Buy a chisel and learn how to make it razor-sharp. Then be very proud when you pare the end grain.

Man, dido on the radial arm saw. I can remember years ago I must of spent months trying to figure out weather to buy a radial arm saw or table saw as my first major purchase. Which one would be the most versitle? Which one would I get more bang for the buck? etc. Gary hit the nail on the head about the accuracy and risks. I ended up buying a used contractors table saw for $80. Amazing what you can do with a little tune up and jigs. Never regreted that decision. As Gary says, its great for cutting crooked cuts. I used my father in laws radial arm saw many times only to be dissappointed. I never could get the thing consistantly dialed in.

Enough on the radial arm saw. Just recently decided to start arming up with wood working equipment. And I find it funny how it falls in line with Rogers advice. Maybe a coincidence, but a few weeks ago I bought some cheap chisels along with wet stones to keep em razor sharp. AW has some great how to videos on how to sharpen. Wet stones are easy to maintain and use. I reccomend a honing guide as well. Razor sharp chisels and planes are the bomb!!!! I revived an old block plane I've had for over 25 years. Amazing how a sharp blade brings it to life.

And finally, I just purchased a bandsaw two weeks ago. A great addition.

Another recent great tool addition, a Veritas shoulder plane.

Currently working on a garden bench with lots of mortise and tenons.

But looking back, these weren't my first purchases. My first were very similar to what's mentioned below. Circular saw, electric drill, router, etc. And slowly over the years you figure out what you need next for that next eye popping project.

Thats how I started, a chisel and 1,000 dollars worth of tools to sharpen the chisel. Now I use sand paper..

I guess we all have a favourite tool. I have been asked many times what I would buy if there was only one tool I could select. I would buy the biggest and best router on the market. My second tool would be a good book on woodworking and they would be followed by my table saw.

A router can do many tasks including acting as a planer, jointer, saw and yes, a chisel.If you can build a jig the tasks it can accomplish are endless.

I, too, thought the radial arm saw ( Sears) was the answer. It was the first major tool I purchased and within a few hours I realized it was also one of the most dangerous tools around. It was very quickly put up for sale and was sold within days. I then used my tiny brain and went to a furniture craftsman and asked his advise. He told me to buy the best tools I could afford starting with a table saw and a jointer. I bought the table saw (Sears) and jointer (Delta). After 30 + years I still use that Jointer but that Sears saw was gone in a year. I have had 6 table saws but once I bought a General saw I had no need to change. I still don't have a good band saw but it is on the top of my list for 2010.

I have several dozen chisels but I have one special set of bi-metal Japanese chisels.

My one piece of advise is that anyone buying tools for any hobby or trade should buy the best within budget.

The four most use full power tools I find most use full are the band saw, table saw, sliding miter saw, and the drill press. Of these I have found most useful. Once it is tuned up I find it easier to setup and safer then the table saw. I use the band saw for ripping, cutting small parts, and I have found I cut many more start cuts than curves. I found it very use full for ripping. I found out this when I was trying to rip some 4in hard maple. It would bog down the table saw, 220v 1¾ HP, and produce as much smoke as saw dust.

I was considered a radial arm saw until I saw the price and used one for a couple of cuts and found it very awkward. So I decided to get a sliding miter saw and this was a worthwhile purchase. I find it makes very square cross cuts.

I like Gary's Yates bandsaw :) And I can't agree more with spending a little extra because I think the bandsaw is one of the tools where you get what you pay for. The difference between my old 14"delta and my 20" italian saw is phenomenal.

Gary's comment on the RAS made me smile. Years ago a friend asked me to help him refinish his mom's redwood deck at her home in Colorado Springs. Long story short, we wound up taking it apart piece by piece - rails, stiles, deck boards - they all came off and got individually sanded and stained. It took us two very long days. When it was over, Mrs. S. expressed her appreciation by giving me her deceased husband's Sears Craftsman Radial Arm Saw. It was a thing of beauty and I was extremely greatful. Until I tried to do anything but a crooked crosscut with it. I must have spent fifty hours trying to get that saw tuned to acceptable accuracy. It never happened. I finally found a buyer for it over ten years later. I agree that it's somewhat about the acquisition of the tools. Get the chisel and the bandsaw and just keep building. But also do yourself a favor and get a nice backsaw and some hand planes. Just build it.

What ever you do; purchase all your stuff as cheaply as possible - go to a big box store and get the stuff from China. Spend lots of hard earned cash on under designed, poor materials, and fancy advertising. Take it home and set up shop. Tackle a corner cabinet with a curved door using your newly aquired woodshop.

Once you've returned your purchases, burnt your wood in the fireplace, and recovered from the nicks, cuts, and bruises caused by starting off the mark too quick then:

Learn to use a marking gauge and a story stick instead of a ruler.

Remember to reach for a hand tool before a power tool - power tools only mean you are going to make the same mistakes you make with hand tools - faster.

Over 25 years ago when I decided it was time to purchase a radial arm saw, I fell for a demo at a home show and bought a Shopsmith with the jointer attachment. It perfors a whole bunch of different operations and doesn't take up a lot of floor space (which I never seem ro have enough of. To date, I have no regrets. Granted, it does not have the capability of a cabinet makers table saw, but it does the job. I never did get the radial arm saw and from the above comments, I guess I really don't want one. I must say though, that my old sears 11 inch bandsaw probably gets the most use out of all my power tools.

I'm just getting started in woodworking-- so hang with me. I have a decent set of hand tools-- some of better quality than others. Everything I've bought to date has been out of necessity. We bought a 1940's house. And it has needed major repair.

So my first big purchase was a miter saw-- I bought a slider with an exceptional blade guard (DeWalt) after witnessing my 70 year old father-in-law slice his fingers up (nearly off) by raking the back of his hand across an old one that was spinning down.

My first major project was building raised-panel wainscoting for our dining room. To accomplish this, I purchased a routing table (Bench Dog portable with a massive Milwaukee router) and a portable table saw (Bosch).

Now I'm hooked and I am trying to build a serious work bench. I've bought a couple of very high end saws, and a smoothing plane from Lie-Nielsen, a Veritas low-angle jointer plane, and I just bought a drill press, a Ridgid, which got high marks. I've discovered pipe clamps are much more cost effective than fancy trigger-grip style clamps, and seem to work better, too.

My biggest hangup at the moment is how to joint the wood. I'm building the bench that will-- in the future-- clamp down my work pieces. How do I hold the material steady for planing with the jointer plane, without a bench? I'd like a power jointer eventually, but can't spare the $600-1000 dollars right now. Do I pursue a Jawhorse type device? Buy a cheap $250 Delta planer to get through this initial phase? I'd love to hear your thoughts and suggestions.

A band saw hasn't been in the plan until reading what you all are saying here.

Regards,

Michael

Whatever you start with, buy the best and only cry once.

I think woodworking and math have similarities. You can learn basic addition, subtraction, multiplication, and division and get most of the job done. In woodworking, the basics are measuring/marking tools, handplanes, chisels, and handsaws. Thats what people used for hundreds of years and built fine furniture. Not to mention homes, boats, wagons, and most everything else!

I think a solid understading of handtools and the concepts behind them would make every woodworker better. It would also make everyone appreciate whow a good powertool increases productivity, especially in stock preparation.

So I recommend starting simple with a decent handsaw, chisels, hand planes, and combination square.

Funny about your herk of a bandsaw. I have just the opposite. I bought a 10 inch Inca bandsaw from Woodcrafters there in Portland in the early 80's. I have never had any drift problem either. Can cut the max 6 inch height veneers with the little 2 inch fence and they come out perfect. Maybe quality can be found in smaller things. Inca tools were great; too bad no longer sold in the US.

The most important tool investment you cam make is to improve the one between your ears. Attend seminars, watch the online videos, take classes. Learn the purpose of tools, how to adjust them, how to maintain them, and how to use them.

I grew up with my father's Shopsmith, which I still have and use. I had a Craftsman Radial Arm Saw, which I sold because of the crooked crosscut syndrome. I worked in a cabinet shop when I was in college and learned to use power tools to do everything. 40 years later, I've finally purchased a few premium hand tools and I'm learning to use them correctly. Now I make more shavings than dust and enjoy it more.

Don't buy anything because it's cheap. That's all it is.

Enjoy.

I too started out when the radial arm saw was queen of the shop. And found out it was more like the queen of harts in Alice in Wonderland. I got by and I did some interesting and creative work with the thing. And survived. Today it's still there, more or less permanently locked at 90 deg. Still good for careful cross cutting with a fine blade and (I think) still the easiest for dadoing (you can see the cut).

Knowing what I know now, I'd buy the biggest baddest band saw I could almost afford. I get by with a dinky table saw and a big out feed table. With the radial saw I'm stuck with and a chop saw I rarely cross cut on the table saw. The little table saw saved me enough to buy a whole lot of other goodies, including a nice chisel or two.

My first tools were a craftsman drill and circular saw (and I still have both after 30 years), but the most useful tools for me was the beginning woodworking class at a local community college. The most useful lessons for me were how to use many different tools safely and how to make jigs for different applications.

Gary:

Your comments are just what I have learned from some expert woodworkers that use a bandsaw for ripping, re-sawing and a number of other operations. Those wonderful old cast iron machines are either hard to find or are only available as a 3-phase motor. I am shopping for a modern version but with the precision and balance you speak. What do you think of the General-Canadian made 20 inch?

I was Lauguna also but there is no distributor close to North Carolina that I know of. I want to touch and feel before I buy. Also I want one that has an effective dust removal design. My old rockwell 14 inch has been adapted with two dust ports but it still generates a cloud of dust?

Due to space limitations, my woodworking has been mostly with hand tool. I first aquired a collection of chisels on an as needed basis. I finally made my big purchase and graduated from a Milwaukee electric hand saw to a Delta 14" band saw. I have never regretted buying the band saw. The band saw allows me to do what I need to do accurately and easier.

Buying good blades and maintaining proper blade tension solved the drift problems. It seems many brand name blades have stamped teeth and are dull right from the start. These poor blades are one reason why so many articles are written on how to tune up your bandsaw.

Jeez. The best thing you can do for yourself to start is get a decent (note that I did NOT write "good") woodworking bench. Which includes, by definition, a decent (again, not necessarily "good") woodworking vise ...start with an end vise, but you'll eventually need a face vise too.

If you don't have any other tools at all to start with, at least you'll have something you can do other things *on*.

Using an actual woodworking bench means that all those squirrely ways that you try (or have tried) to clamp things down to use your hand tools effectively, won't be - and aren't - necessary.

You'll be amazed at what you can do with a sharp handsaw, an old Stanley handplane (start with a block plane, a no. 9 1/2 ...you'll end up with most of 'em, but start with the 9 1/2, which you'll almost *always* reach for first ...you can sharpen 'em with graduated sandpaper on a piece of tempered glass: google "scary sharp"), and a good bench chisel set (you want a wooden mallet for using chisels, and NOT a metal hammer) ...IF you have a decent woodworking bench.

As for that first - and subsequent - handplane? - Google "shooting board". And as for buying old handplanes when you live in the middle of nowhere-they've-ever-heard-of-flea-markets: eBay is your friend.

...and you'll have a big head-start on accurate joinery.

From there. Get a router and bits. Make a saw-horse or three and get a circular saw (for cutting up plywood: a handsaw sucks on plywood ...and a tablesaw ALSO sucks, on full sheets, at least) and a 40T blade (it will come with an 18/24T rip blade). Get a battery drill and wood bits and forstner bits: buy the very, very best lithium ion drill you can, and make sure you have two batteries.

NOW - if you have the space - you're ready for a band saw (I quite agree with that). A jointer. A planer. And, finally, a table saw.

...and by starting with a "decent" woodworking bench will also allow you to consider building ...a GOOD woodworking bench.

Yes I would agree 100 % with Band Saw purchase. The one "toy" I have yet to purchase, that said allow me to make a suggestion. Please, Please find a Voc-Tech School in your area and puirchase a night / Extension course. I cannot express how much joy I have experienced making and gifting my projects using the big boy toys I would never be able to afford. After several bad choices I found a school 18 miles from my home. ( I have a voc-Tech within walking distance )I fit right in with the instructor and the group, some have been in the same night for 15+ years. I just short of my 60th birthday and cannot wait until my next school night. My decision to find the right class was the very best tool I have purchased to date. Ronnie, East Taunton,Ma

I kind of agree with Peter and tdruth.

I started woodworking using simple tools to cut 2 x 4s, plywood and drill holes. Some basic hand tools, a good drill, good circular saw, and some kind of sturdy bench, will allow a beginner to build many things. I also bought a router early on, but quickly realized that without a good assortment of quality and, at the time, expensive bits it was not that useful.

My first big tool was a good table saw, and I did a lot of things on this saw and I still use it regularly. I just bought a good 20" handsaw, so I can't comment since it is not yet connected. But the first one, a cheap 10" with 1/4hp motor, was never used and I just gave it away. My only experience on a radial arm saw was on my father-in-law saw, and that was a scary one (hence the table saw).

But my most frustrating memories are all related to using dull tools. I used to think that you could not reproduce the factory edge on average tools bought at the hardware store! After spending almost a thousand on various gadgets, I now use a cheap dedicated belt sander with a quality tools holder and a good assortment of water stones with a Veritas guide, and I am quite happy with the repeatable results. In my opinion the quality of the tools holder and guide is far more important than the belt sander.

Guy

I have two comments for those getting started. You don't need a lot of tools to get started with woodworking, and I would agree that you need a good set of chisels. For power tools, my first real tool was a Sears Contractors saw on which I added a good after-market fence. It did me well for years.

1st lesson about tools. If you buy cheap you will end up buying it twice. The second time it will be the better tool after you learn that cheap tools are harder to get results.

2nd lesson is start with simple projects, but not so simple that it does not test your skills. As you take on more complex projects, add the new tool necessary to do that project well.

Over the 18 years I have been doing woodworking, I have acquired 90% of what anyone would need.

By the way, I just replaced that old Sears saw with a brand new SawStop Professional. Sweet saw!

The big surprise for me, as a beginning woodworker, is how often I reach for a hand plane. I use my planes all the time - to joint boards flat and square, to trim wood after a saw cut to get super-precise dimensions and invisible glue lines, to shave down tenons, to trim dovetails and flatten glued up panels, and to eliminate, almost completely, the thing I like least: sanding.

But it's not just that a plane is often the best or even the only tool for a job. It's that a well-tuned plane brings me closer to the essence of woodworking than anything else. I often work at a local shop that is stuffed full of power tools, but more and more I choose to face- and edge-joint my own lumber, because I can actually feel the wood that way. I don't know why that matters to me, but I guess part of it is enjoying the process of making something, and not just rushing to get to the end product in the quickest way possible. There's nothing like the sound and feel of that shaving curling smoothly off the blade and the clean smell of the fresh cut wood.

So I would say, after you buy the bandsaw, get a really good plane (I started with a 7-1/2 jointer, which is maybe a little unconventional) and learn how to sharpen it. You might find a whole new way to enjoy what you're doing - and that's a great thing to get from a tool.

Start wood working?? You mean as a hobby??

Never

Now pay me and I will make what ever you want. :)

I entered into woodworking with one goal to do it for a living and you know I never thought of it any other way.

But seriously even if your goal is just to make a feel things yourself as a hobby my advice is the same your first investment in wood working should be to acquire knowledge way before you purchase any tools.

Many wood working tools in the hands of anyone with out the required skills and knowledge will at least ruin a lot of wood and at worse take a good piece of your hand, eye. Even hand tools can cause a good wound and some power tools can even cause a fault blow. A work piece turned projectile striking the right place can do a job.

I apprenticed with a veteran cabinet maker and you know unlike a lot if shop teachers he had all his fingers and both eyes. Proper technique is the best safety devise ever.

The advice about taking a course at a Voc tech school is a good idea also there are many other wood working schools around the country. And the best thing is you get to learn how to use tools without having to go to and buy them first.

What tools you need depends a lot on what you want to make and just how quickly you want to make it. My whole house was including all the raised panelling trim windows frame, every floor board and even the nails was made with out a single power tool. And some of the most beautiful furniture ever made was made in the 18th century all with hand tools. So if you want you could make anything without any modern large stationary shop tools. Of course making furniture completely with hand tools takes much more skill then power tools. But can be much more rewarding.

Now since my goal was to make a living doing this power tools are a necessity for and some pretty big expensive ones at that.

But if I was to do it as a hobby I would go the Roy Underhill route and do it as they did in the 18th century from tree to furniture with out a single power tool.

You still will need to spend a good bit of money and you will need to search a few flea markets for many of the tools you just do not go down to the Home Depot to buy a draw knife, and shaving horse or a Spring pole lathe or even a good morticing chisel.

This article by Gary Rogowski was right to the point and is an example of why he is one of my favorite contributers. It is just what I would expect to hear from a professional woodworker. Here is a sentence from another of his articles "Time spent in the shop is as important as what comes out of the shop." So get a chisel, get in the shop and learn how to sharpen it.

My first benchtop tool was indeed a bandsaw. It was actually years afterward that I got my first set of chisels. My next major tool was of course, the table saw. Between the two of them I made an awful lot of stuff. I bought as my needs and skill level grew. Unfortunately, I now need a much bigger workshop....so I can buy more tools.

One thought on tool purchases is that you should buy the best you can afford. Maybe stretch yourself a bit and buy a bit above your budget. If you budget dictates cheap tools, buy cheap. At least you will be working with something. You may buy it twice, but waiting til you can afford something sometimes ends up with nothing at all, a missed opportunity. If you buy cheap power tools, be sure to get those planes and chisels because you jointery will need some fine tuning.

I bought a lot of old tools the needed to be rebuilt to be operable and that is a project in itself. You spend time rebuilding a tool and spending time that you could be doing woodwork. So if you don't love tool rebuilds, buy one that is working.

I also bought a radial arm saw and have yet to use it for the above mentioned reasons. I should probably sell that thing.

One thought on tool purchases is that you should buy the best you can afford. Maybe stretch yourself a bit and buy a bit above your budget. If you budget dictates cheap tools, buy cheap. At least you will be working with something. You may buy it twice, but waiting til you can afford something sometimes ends up with nothing at all, a missed opportunity. If you buy cheap power tools, be sure to get those planes and chisels because you jointery will need some fine tuning.

I bought a lot of old tools the needed to be rebuilt to be operable and that is a project in itself. You spend time rebuilding a tool and spending time that you could be doing woodwork. So if you don't love tool rebuilds, buy one that is working.

I also bought a radial arm saw and have yet to use it for the above mentioned reasons. I should probably sell that thing.

One thought on tool purchases is that you should buy the best you can afford. Maybe stretch yourself a bit and buy a bit above your budget. If you budget dictates cheap tools, buy cheap. At least you will be working with something. You may buy it twice, but waiting til you can afford something sometimes ends up with nothing at all, a missed opportunity. If you buy cheap power tools, be sure to get those planes and chisels because you jointery will need some fine tuning.

I bought a lot of old tools the needed to be rebuilt to be operable and that is a project in itself. You spend time rebuilding a tool and spending time that you could be doing woodwork. So if you don't love tool rebuilds, buy one that is working.

I also bought a radial arm saw and have yet to use it for the above mentioned reasons. I should probably sell that thing.

One thought on tool purchases is that you should buy the best you can afford. Maybe stretch yourself a bit and buy a bit above your budget. If you budget dictates cheap tools, buy cheap. At least you will be working with something. You may buy it twice, but waiting til you can afford something sometimes ends up with nothing at all, a missed opportunity. If you buy cheap power tools, be sure to get those planes and chisels because you jointery will need some fine tuning.

I bought a lot of old tools the needed to be rebuilt to be operable and that is a project in itself. You spend time rebuilding a tool and spending time that you could be doing woodwork. So if you don't love tool rebuilds, buy one that is working.

I also bought a radial arm saw and have yet to use it for the above mentioned reasons. I should probably sell that thing.

One thought on tool purchases is that you should buy the best you can afford. Maybe stretch yourself a bit and buy a bit above your budget. If you budget dictates cheap tools, buy cheap. At least you will be working with something. You may buy it twice, but waiting til you can afford something sometimes ends up with nothing at all, a missed opportunity. If you buy cheap power tools, be sure to get those planes and chisels because your jointery will need some fine tuning.

I bought a lot of old tools the needed to be rebuilt to be operable and that is a project in itself. You spend time rebuilding a tool and spending time that you could be doing woodwork. So if you don't love tool rebuilds, buy one that is working.

I also bought a radial arm saw and have yet to use it for the above mentioned reasons. I should probably sell that thing.

One thought on tool purchases is that you should buy the best you can afford. Maybe stretch yourself a bit and buy a bit above your budget. If you budget dictates cheap tools, buy cheap. At least you will be working with something. You may buy it twice, but waiting til you can afford something sometimes ends up with nothing at all, a missed opportunity. If you buy cheap power tools, be sure to get those planes and chisels because your jointery will need some fine tuning.

I bought a lot of old tools the needed to be rebuilt to be operable and that is a project in itself. You spend time rebuilding a tool and spending time that you could be doing woodwork. So if you don't love tool rebuilds, buy one that is working.

I also bought a radial arm saw and have yet to use it for the above mentioned reasons. I should probably sell that thing.

I've thought about this kind of a purchase order list idea for many years. My first power tools were just a cheap circular saw, jigsaw and corded drill. The need for a table saw forced me to turn that circular saw upside down and plunge it through a small piece of plywood that I built a stand for. The first generation of Vise-Grip's "Quick Clamps" was used to fasten a straight-edge. After buying a better quality circular saw, I left that one in the stand and it lasted me for years. The first major tool investment was a good cabinet saw with a Forrest blade. Buying a bandsaw as one of your first big purchases may be called for if fine furniture is your main preoccupation, but I'm just looking into getting one now after building make-do furniture for years along with a whole house - including cabinets. I got a decent set of chisels this past Christmas (after leaving post-it-notes in the Lee Valley catalogue) but cheap ones have been fine so far. The fine furniture I want to tackle now is a luxury, not a necessity. Sanders, routers, drill press, planer, - even chainsaws have been far more necessary (Okay, so the chainsaws were for a couple log houses - but still got a bit of use for the last stick-built). I used a simple jig with a router to level the top of of Fine Homebuilding's "New-Fangled Workbench" in 1999 - a great, easy bench to build by the way. But, after thinking about this again, the tool I find most useful is not a power tool at all but a simple hand sanding block which fits belts from belt sanders. I use it much more often than my block plane.

Buy the best you can afford and then some and if you lucky buy barely used. I began my woodworking hobby with just an old table saw, router and a few hand tools that my father gave me. I built several simple projects and these tools were adequate. Once my skills and available money increased I bought better tools. Most of the tools in my shop I purchased second hand and all of them were like new when I purchased them. I saved a bundle and bought far better tool than I could afford if I bought new. So by advice to new woodworkers is to start simple and build you shop as your skills get better and your tool need increase and spend the most on the tools you will use the most.

I am 65 (and never thought of woodworking and could not drive a nail)and 3 years ago inherited my father in laws table saw, small router, 3 sets of chisels, 3 broken hand planes and so many clamps I thought I'd never need. As it turns out, I've had to purchase more clamps! The table saw was a Delta Unisaw which cut great except it could not cut a straight rip. After having it checked out, the fence was bowed and would need to be replaced. After checking prices I decided I did not want to spend $500 for a new fence for a 22 year old saw so I donated the saw and purchase a new Delta Cabinet Saw. After a lot of consideration a did what I thought was an "up-grade" to a 220v 3 1/4 HP unit. I have always thought having something that will not only do the job at hand but have extra power to spare is money well spent. I too have purchased inexpensive (let's face it, nothing is cheap anymore) tools and have gone back for the upgrade to better quality. I've since invested in 2 hand held routers, 1 plunge router and of course the PC 7518 for my router table. Not to mention the $$$$ spent on other items needed.

I am glad to hear from Gary about the band saw. I have gift cards I've been saving for just that. I believe now a band saw is one tool a person needs. After several "mishaps" on the table saw one geats leary and wonders if "it" really needs to be done on a table saw. Of course I've grown more careful too. You don't "attack" a job on the table saw least the saw will attack you.

One of the first things to learn is patience. Take the time to think out what you are doing and the safest way to do it. Rushing anything in woodworking will lead to more time doing the job over or waiting for a wound to heal. I know from experience.

After all that, I still love it and only wish I had started at a much earlier time in my life. There is so much to learn. My one desire: To build a piece of furniture, desk, table or whatever, that my children will want to keep and hand down to my grandchildren and their children. Who knows, maybe it will happen.

Thanks,

Jerry

I've been a framer for close to 30 years. my main tools used to be circular saw hammer and tape. I also did my fair share of trim work and hung many a door.

From all my experience I found that knowing how to use your tools is the greatest tool you can have. Even after 15 years I managed to almost take part of my finger off.

My uncle was a furniture maker and he made a lot of his own planes. I remember 20 years ago I helped him build some kitchen cabinets with just a skill saw and a framers square. He made panel doors and bought the trim for the top.

That really inspired me, Recently I have built a set of kitchen cabinets and next would like to make some furniture pieces.

But some of the first tools I bought for finishing carpentry were a table saw, a router (2 1/2hp with 1/4 and 1/2 collet, router table, jig saw a mouse sander, and a decent set of chisels. Had a decent plane, drill router bit set and frostner bit set. It was pretty expensive. But considering the money I saved on building my own kitchen cabinets even with the cost of materials. I still only paid a quarter of what it would have cost me buying the cabinets. with some tips from the net and making some homemade jigs, you can do some pretty amazing things with patience and know how.

My next tool on my agenda is a table saw. There are so many things we can make for a fraction of the price if we bought them. So even though the tools seem expensive, just think how much money you'll save in the long run.

Sorry gys I meant to say my next tool on my agenda is a band saw and a good power jointer and planer. If you have any suggestions for these tools, makes and model numbers, I would really appreciate it. Thanks in advance joe

Log in or create an account to post a comment.

Sign up Log in