I came up with this very unique and satisfying version of a clamp worktable, made right here in my shop, using material from my sheet goods scrap pile. I designed it so I could use my collection of ordinary and fast action vise clamps meant to be used at the drill press.

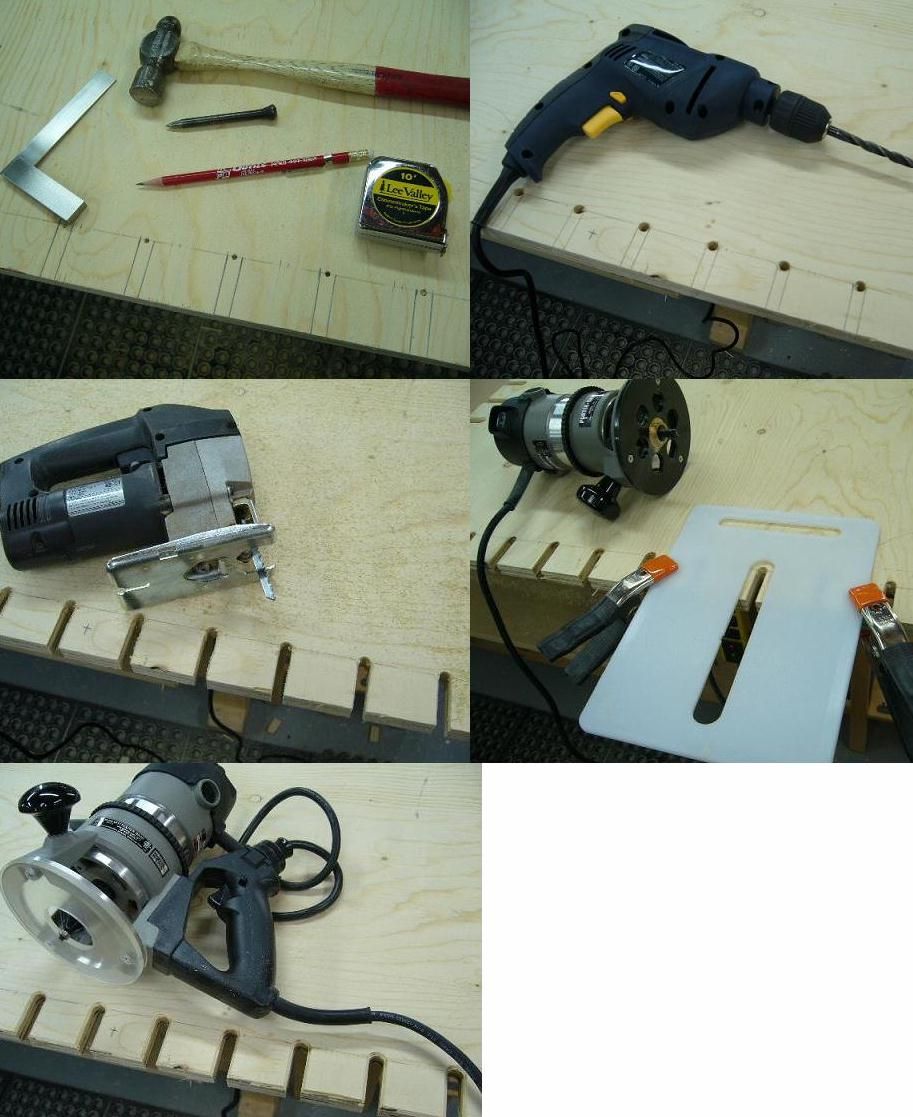

As shown, a 30″ X 36″ base is made out of 3/4″ plywood, which is notched every 2-1/2″ around the perimeter, 2″ deep, to accept the vise clamps’ shank without removing (threading off) the O-nuts. This base is usefull to hold workpieces for sawing, carving, routing, sanding, etc. The clamping action is quick and positionning the vise clamps is nearly unlimited.

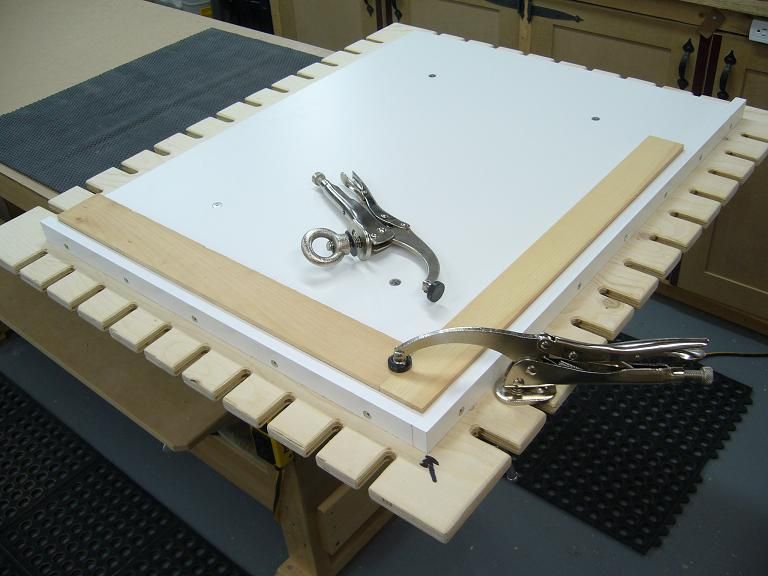

I also made a 30″ X 24″ sub-base out of 5/8″ thick Melamine (so glue won’t stick to it), on which I’ve added a 1-1/8″ edge strip on 2 sides to register workpieces when required, like when drilling pocket holes, building drawers and carcasses square. Since those strips are screwed on the edge of the sub-base, they protrude 1/2″ over the top surface giving me the registration edges I wanted. Here again the multi-positions feature I can get from the vise clamps is just incredible. To be removable, this sub-base is held to the base with four 1-1/4″-long 1/4-20 f.h. bolts and four 1/4-20 T-nuts installed from under the base.

To prevent the jig from slipping or creeping, I throw a router pad on the workbench, shop cart, Workmate, router table or sawhorses and I’m ready to go. When needed, I also clamp the base. I’m thinking about adding a removable block (with T-nuts & bolts) under the base so it could get clamped in the Workmate or the workbench vise to prevent it from creeping when side pressure is applied.

This is my best shopmade jig ever. Attached are some uses for this great jig.

For more details and photos, find it here on my website.

Best,

Serge, http://www.atelierdubricoleur.spaces.live.com

If you don’t want to build your own, you can buy one similar made by Kreg from:

http://www.rockler.com/product.cfm?page=18025&filter=kreg

Comments

Great idea! If I every have to make a set of kitchen cabinets, I will probably make one of my own!

I would like to look at these sites. . .but none of them seem to work . . .

Mr. Block,

Both links work for me.

Very difficult to read this information with the dark brown background. I'm not even going to try.

Looks good. I'm gonna make one. But did you know that vise grip drill press clamps work without the nuts on the bottom? If you drop them into a hole just like an old fashioned holddown they jam in the same way when pressure is applied to the clamp. I have a large wooden add on table for my drill press and have placed a couple of holes where I use the clamp the most. The threads on the vise grip bolt work so well that they grip the hole walls at whatever height they are in the hole. I don't usually even have to adjust the clamp pressure at all, I just lower the clamp in the hole till the clamp sits on top of whatever thickness stock I am drilling and I push down the handle and the bolt jams at that height and the clamp clamps. That said, you are stuck with the position of the hole. Your design using slots gives you more options. Thanks for the great jig idea.

I've been wanting to make these jigs ever since I saw it in my Shopnotes magazine.Perhaps they got this design from you. I like it because it seems I'm always struggling to find enough clamping positions on my workbench edge. I also like the portable line boring jig shown. I have the ones designed to drill these shelf holes with a portable hand drill, but they don't drill a nice clean tight hole like a line bore does and I don't do enough work to justify the cost of a dedicated line bore machine. So I'll be making both these jigs.

Log in or create an account to post a comment.

Sign up Log in