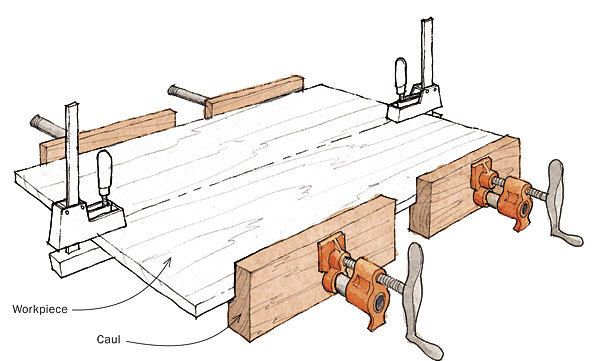

Pipe-Clamp Cauls Put Pressure Where You Need It

These clamp cauls not only position edge-glued stock at the center of pressure on the pipe clamps, but they also help spread the clamping pressure along the length of the workpiece and protect the edges from bruising. They make the clamping process much faster and easier.

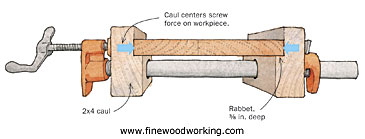

To make them, first bore a hole (sized to slip over the pipe) about 1 in. from the edge of a 2×4. Then cut a 3/8-in.-deep rabbet in the 2×4 wide enough that the clamp head is centered on the edge of the material you’re gluing up. This width will vary with stock thickness. This puts the clamping pressure right where you need it.

The cauls I use most of the time are 10 in. long, and I keep them on my pipe clamps. But I have longer and shorter cauls for different-size jobs.

Fine Woodworking Recommended Products

MicroJig Matchfit dovetail clamps

Double Sided Tape

Incra Miter 1000HD

Comments

This looks great. Slight modifications suggest themselves for use with F style or Parallel Jaw clamps. Would help keep work off clamp bar and provide more stability while doing the glue up. Thanks.

Dave

I'll have to Make-Up some of these Myself! It sure Beats using Scrap pieces when Clamping Glue Ups like I usually do!

These are great and I have used them in numerous glue ups here are my tips:

Select straight grain construction lumber which has at least two months of drying in your shop. Use only boards that are not twisted or bowed, ideally avoid plain sawn and use only quarter or rift sawn.

Mill all the rabbets at same time then cut the cauls to length. After cutting to length, Drill all the pipe holes at same time, use drill press for repeat accuracy. Wax all the caul rabbets

Curved cross cauls if used to keep the middle of the glue up flat and evenly aligned need the support of flat cross cauls under the glue up to avoid gluing in a permanent curve into the work.

Mill and joint dead flat cauls to support the underside of the glue up. The flat cauls should be the same height as the shoulder of the rabbet in the pipe clamp cauls. These should be waxed or taped with plastic packing tape as they will be exposed to glue squeeze out and you do not want them glued to your work.

Thanks Mark, it is great to stand on the shoulders of giants

Frank H.

Log in or create an account to post a comment.

Sign up Log in