Bench-Vise Secrets

You're probably not getting the most from this workshop workhorse

Synopsis: The bench vise is one of woodworking’s most necessary and fundamental tools, vital for holding work while you saw, chop, pare, plane, scrape, and perform any number of other tasks on your projects.

Despite the vise being used so often, it is commonly misused. In my class or at workshops, I routinely see beginning students clamping stock the wrong way in the vise, sawing or paring in the wrong direction, and risking injury when the work slips and the tool jumps.

The bench vise is one of woodworking’s most necessary and fundamental tools, vital for holding work while you saw, chop, pare, plane, scrape, and perform any number of other tasks on your projects. despite the vise being used so often, it is commonly misused. In my class or at workshops, I routinely see beginning students clamping stock the wrong way in the vise, sawing or paring in the wrong direction, and risking injury when the work slips and the tool jumps.

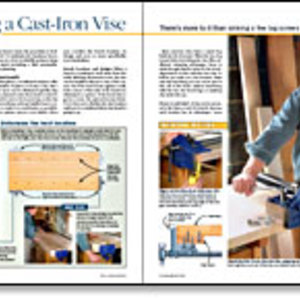

Too tall. It’s tempting to place the stock high in the vise so you can work without stooping. But this lets the workpiece flex (right), making the task more difficult and the results less accurate. For the best support, keep the stock low in the vise (below left) or brace it with a backing block of thick scrap stock (below right).

You can avoid mishaps like that by adopting a few basic techniques to hold your work securely and prevent it from slipping. and with a few simple shopmade fixtures, you can use your vise to tackle an even wider variety of tasks safely.

Many ways to use the vise alone

I typically use my bench vise in one of three ways: by itself, with benchdogs, or with other clamping fixtures. Let’s look at all three.

On its own, the vise is great for holding smaller workpieces during sawing, chisel work, edge-planing, or other tasks. But for best results—and safety—it’s important to orient the work properly in the vise.

For vertical work, consider your task and orient the workpiece so that you’ll be working across the jaws and not in line with them. You want the back jaw to brace against the thrust of the saw or chisel. also, to reduce the likelihood of slipping and racking the vise, position the stock between the vise screw and a guide bar, as low in the jaw as possible. The farther up from the jaws the operation gets, the greater the potential for losing control.

From Fine Woodworking #212

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Veritas Wheel Marking Gauge

Lie-Nielsen No. 102 Low Angle Block Plane

Starrett 12-in. combination square

Log in or create an account to post a comment.

Sign up Log in