Building a Thickness Sander

A large drum turns an abrasive machine into a smooth operator

Synopsis: Like most other woodworkers, guitarmakers routinely need to plane and smooth wide, flat pieces of wood for instrument parts. Unfortunately, the job is usually too delicate for most stationary thickness planers. The alternatives are scraping, hand planing and hand-sanding the wood or running the stock through a thickness sander, if you have one at your disposal

Like most other woodworkers, guitarmakers routinely need to plane and smooth wide, flat pieces of wood for insn-ument parts. Unfortunately, the job is usually too delicate for most stationary thickness planers. As guitarmakers, we often have to plane the sides, back and top of a guitar to ’11 0 in. or less, and most planers don’t surface stock much dunner than ‘Is in. Further, many of the wood varieties typically used by guitarmakers, such as rosewood, curly maple or koa, are susceptible to splintering and tearout from the cutting action of a thickness planer. The alternatives are scraping, handplaning and hand-sanding the wood or running the stock through a d1ickness sander, if you have one at your disposal.

Thickness sanders come in several different styles. Tbe Cadillacs of the breed are the wide-belt sanders: expensive machines that sport power feeds, accurate thickness adjustments and oscillating sanding drums. The lower-cost alternatives are drum sanders that have a small-diameter drum, wind-on sandpaper and manual feed. The problem with these is that resinous woods, like rosewood, easily clog d1e small surface area of the sandpaper. We considered building one from mail-order plans, but those we saw were so poorly conceived, we decided that we could design and build a better machine ourselves. The machine we came up with, shown at right, fulfilled our basic tenets: it was quick and inexpensive to build and it operates to close tolerances. Building the machine requires mostly woodworking tools and skills and very little metalworking. It will be a welcome addition to any woodworker’s shop.

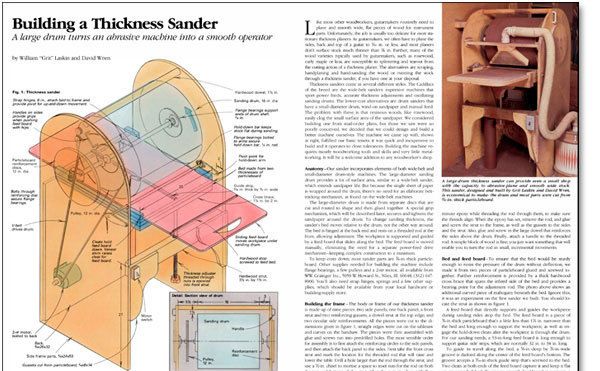

Anatomy-Our sander incorporates elements of both wide-belt and small-diameter drum-style machines. The large-diameter sanding drum provides a lot of surface area, similar to a wide-belt sander, which extends sandpaper life. But because the single sheet of paper is wrapped around the drum, there’s no need for an elaborate belttracking mechanism, as found on the wide-belt ma ci1ines.

The large-diameter drum is made from separate discs d1at are cut and routed to shape and then glued together. A special grip mechanism, which will be described later, secures and tightens the sandpaper around the drum. To change sanding thickness, .the sander’s bed moves relative to the drum, not the other way around. The bed is l1inged at the back end and rests on a threaded rod at the front, allowing adjustment.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Grizzly G0495X Industrial Helical Cutterhead 8-in. Jointer

Rockler Dust Right 650 CFM

DeWalt 735X Planer

Log in or create an account to post a comment.

Sign up Log in