Most woodworkers are underclamping their joints during glue up. To help avoid this, professor Roman Rabiej developed some simple keys to clamping success. (Read the full article on the topic.)

One of the keys is to use the right number of clamps for the job. So Fine Woodworking tested common bar clamps to determine the strenth of each.

The force applied by each type of clamp varies greatly depending on the strength of the operator. FWW conducted a test using four different staff members; two Fine Woodworking editors, our female copy editor, and a brawny Fine Homebuilding editor. The numbers in the chart are the average of the FWW editors. The copy editor in our test consistently applied about 60% of the average clamp pressure, while the hand strength of the FHB editor was about 40% higher.

|

Parallel Jaw Clamp 370 lb. |

|

Quick-Grip Clamp 470 lb. |

|

Aluminum Bar Clamp 680 lb. |

|

3/4-in. Pipe Clamp 1,050 lb. |

|

“I”-Beam Bar Clamp 1,350 lb. |

Details on the test

In his book, Understanding Wood (The Taunton Press, 2000), R. Bruce Hoadley illustrated that the amount of force applied by different types of woodworking clamp varies widely. He also found that the force of an individual clamp can differ by a factor of two depending on the strength of the operator.

To compare traditional bar and pipe clamps with newer designs and to see how the force they apply varies by user, Fine Woodworking rigged up a jig linked to a set of bathroom scales. The magazine’s female copy editor represented one end of the strength scale, a brawny former builder at Fine Homebuilding represented the other, and a couple of Fine Woodworking editors fell in between. Generally, clamps with T-handles exert more pressure than those with round handles.

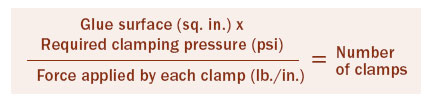

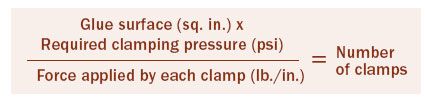

Calculating Clamp Requirements

The first step when gluing boards is calculating the square inches of glue surface. For example, if you are gluing two boards 3⁄4 in. thick and 36 in. long, a single glue surface equals 27 sq. in. Even if you are edge-gluing several boards, you still need to measure only one glue surface because the clamping pressure is transmitted across the width of the boards. If you are edge-gluing flatsawn red oak boards and wish to apply about 450 lb. psi, then 27 multiplied by 450 equals a force of 12,150 lb. that must be applied. Using the average of the editors’ clamping forces, this could be supplied by around nine heavy-duty bar clamps, a dozen 3⁄4-in. pipe clamps, or 26 quick-grip clamps. Obviously it would be hard to fit 26 clamps along a 36-in. board, so add some more powerful clamps if you have them. It’s fine to mix and match types of clamp.

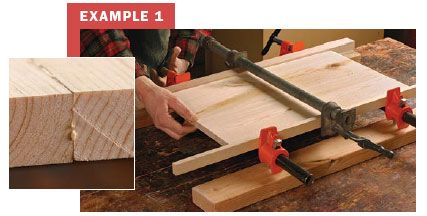

Less pressure for pine. These two pine boards have a glue surface area of 16½ sq. in. Because the glue faces are nearly flatsawn (see inset), the recommended pressure is 150 psi, requiring a total force of 2,475 lb. This can easily be met by using three ¾ -in. pipe clamps.

More pressure on maple. The effective glueline area is the same as for the pine (even though there are three boards to glue instead of two). The glue faces are quartersawn (see inset), so the recommended pressure is 600 psi. This total force of 9,900 lb. requires nine pipe clamps.

Once you’ve determined the right type of clamps to use, you need to determine the best way to distribute them.

Comments

Was it really necessary to point out that your copy editor was female? Would it not have been fine to just mention that she was the copy editor?

Would you have mentioned that one of your participants was hispanic? Or black?

Jeez. Most women aren't as strong as men and therefore it made sense to include the descriptor. He also put info info on the home builder. What is the alternative? Take them down to the gym and measure their strength?

Enuf of the PC whining, be grateful for the important information. Oh, you already "knew" these basics? Then why did you bother reading it, to whine?

Interesting article. It was a good move to mention that the copy editor was female and the other participant was a "brawny ex-builder" for a grip strength comparator. I don't think the average person (outside the industry) has any idea of the physical demands (and resulting muscle development) of a construction profession.

The ex-builder likely spent many years swinging a 22oz framing hammer (the big ones on the rack at Lowes), one-hand operation of a 9 to 12lb circular saw (not those wimpy HO grade ones), lugging stacks of a half-dozen wall studs at a time or 60-90 lb rafters/floor joists. While it's not entirely inconceivable, I doubt the female copy editor had lived such a physically demanding life and quite likely has nowhere near the griping (or otherwise) strength of the ex-builder. I (builder for 27 yrs) have to open jars for my wife (school teacher) all the time, even though she has excellent overall strength for a woman her size.

Armed with the pressure data included in the article, I can do a clamp pressure test of my own with one or two of the clamp styles shown and calculate just how many clamps are needed for the glue-up based on my grip strengh. Thanks!

jeepers, is it a table top, or am I framing my home with small scraps turned dimensional lumber? Is the number of clamps relative to the deflection of your clamping cauls? We have all experienced a 'joint' failure, and I fathom a guess that retrospect did not leave us wondering why. (ie: bad joint and we knew it, left glue too thin in a spot, or the ultimate clamped the hell out of it and squeezed out most of the glue, or 'Iwas lazy and in a hurry so I applied to just one side.)

My 2 cents.

How do you measure clamping force?

Hi, I just read your article on clamping, and as a biochemist with plenty of physics who is just taking up woodworking, I loved the scientific competency of this article.

I do have a couple questions. Your article gave samples of required pressures for edge-gluing several species of wood, but what about the others not listed here? Does this sample run the gamut with everything else in between? We chemists have reference manuals that are basically nothing more than hundreds of pages of measured physical properties for different compounds, and I'm curious to know if such reference manuals exist for woodworking (i.e. lists of recommended gluing pressures for different woods). Thanks for your help.

Maybe someone can explain how a rubbed glue joint works. (without clamps) If the wood was prepared properly in example 2 there would be no need for nine clamps.

Articles like this keep me from renewing my membership.

Your website is great when it works. Some it's accessible; sometimes it's not. Sometimes the links take me to the correct articles, sometimes they don't.

I'm using the latest IOS on an Apple IPad Air 2. If your website were consistently usable, I'd be thrilled. Is there any possibility you could facilitate that?

I agree with your comments about broken links, etc. The database of articles and videos is poorly constructed and poorly maintained. Add in the advertising traps that seem to be part of the database and I get frustrated enough to cancel my subscription. Which I did today.

As a female woodworker I appreciate knowing that one of the testers was a female. It certainly helps me understand the numbers presented. Now I know that the pipe clamps are not just less expensive than others, but they apply great force.

If they mentioned they were black or Hispanic there would have been a slightly higher tax deduction.

I just did an experiment about this on youtube... I tried a variety of different clamping pressures and cure times to see what the optimal setup is. It turns out that you don't need NEARLY as much clamping pressure as you think. I'd love to hear what you think about this: https://www.youtube.com/watch?v=f3eWwETAiyo&t=

Turns out that if you surface your edges properly, even the bare minimum clamping pressure is more than enough.

Interesting. I watched it, great video. We might talk more...

In what world is a quick clamp doing 25% more pressure than a parallel clamp?

Log in or create an account to post a comment.

Sign up Log in