L Shaped Supports

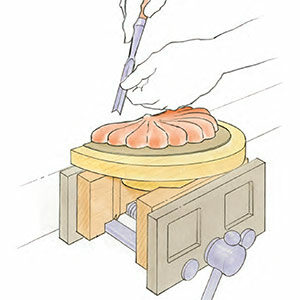

I do a lot of carving for my custom furniture business and one of the challenges is supporting the work–especially for odd shapes like a spindle or turned leg.

Better support than a lathe

Whether you’ve turned them yourself or if you purchased them from a supplier, I find it’s easer to use two L-shaped supports. It provides much more support than using the lathe and this is especially important when carving hard wood.

Good for carving hardwoods

To use the supports, I just screw them to the spindle centers. The spindles in the photos above are solid cherry–a very hard wood to carve. So, I have to use my mallet 90 percent of the time. This puts a lot of pressure on the centers. Each one of these leaves take me around 3 hours for each leaf. There are a total of 8 leaves per spindle.

If I were carving these leaves out of basswood, which is a very soft wood. I would only use my mallet about 20 percent of the time. Then it would be possible to use my lathe to hold my spindle while I carve.

The centers would still take a lot of pressure and could tear the wood and come loose. So in the long run it’s better to make the L supports to support the spindle while you are carving.

Comments

Interesting idea but the only photo showing the support is not very informative. Nice carving though. Would like to see other photos of the support please.

Hi John1910,

Thanks for the complements.

Here are some more pictures of the L Supports, showing closer detail of how they are used.

Dennis - nice work. Some years past I had a commission for a headboard with two bedposts with 30" turned and carved tops. I constructed a similar rig but in order to prevent rotation, I modified both ends to include a clamping arrangement. One end was a slotted hole with a bolt and wing nut to secure. The other end of the workpiece was square so I devised a collet that fit over the square and would rotate within the hole in the bracket, again with a bolt and wing nut. The carving was of California wildflowers spiraling around the post top. It was in walunt. It worked great. Too bad I've never had another use for it.

You do very nice work.

Thank you Dennis.

A great idea, & a beautiful piece of furniture.

if I was doing this job I would leave the centre portion rough turned then hold job by thi s part in a vice mounted on a post held in the bench vice ,the work may then be held and tilted to any convenient angle .when the ends are carved to your satisfaction turn the middle part and make flutes by means of a jig on the spindle moulder or router.,or hold in v blocks to carve flutes by hand. If enough material is left in the middle the metal jaws of the post mounted vice will grip with strength that wood or padded jaws never will ,I have done many such jobs in my 40 years as a self employed wood carver.

Thanks for the article Dennis.

Beautiful work. :0)

Log in or create an account to post a comment.

Sign up Log in