Do you use bamboo in your furniture? Take our poll below. In general, you can purchase bamboo in several ways: as paper-backed veneer, in various forms of plywood where bamboo forms the core and the faces, or as laminated slabs.

Anyone out there using bamboo in their furniture? This renewable material is showing up everywhere from flooring to socks and furniture makers have jumped on the bandwagon too. What about you?

Many turn to bamboo for its sleek appearance and “green” cache. The plant is a fast-growing grass that can take less than five years to mature. Hardwoods, on the other hand, can take decades. The material is also incredibly durable–harder than maple–though tough on tools.

It comes as veneer or as laminated plywood (one brand is named Plyboo). Fine Woodworking readers have put it to use in tabletops, bookcases, cabinetry, boxes, and more.

|

| Award-winning material. This bench by Phillip Sell won best-in-show at the Texas furniture maker’s show two years ago. Photo: Asa Christiana |

Never tried it before? Here are some tips on how to use it from a Q&A in our magazine. This is the only information I found in our archives on plywood, so if you have tips/lessons from the field to share… please post a comment below.

How to work with bamboo

Question from Daryl Boudreaux of Wallingford, Penn.

Attracted to bamboo as a renewable resource, I decided to make a small table using bamboo flooring. I installed new blades in my planer and removed the ridges on the back of the 4-in.-wide strips and the finish layer on the front.

I knew that bamboo is loaded with silicates, but was shocked at the condition of the blades after planing about 1/8 in. off of about 50 linear feet. After cutting the legs on the tablesaw, I tried to handplane the slight mismatches on the glued-up leg joints. I used very sharp blades at a high angle but still got extensive tearout. Scrapers worked but became dull so fast that they were not a realistic option either.

Answer by David Ebner, a contemporary furniture maker from Brookhaven, NY

I’ve worked with solid-core bamboo plywood and with sheets of bamboo veneer. I stack solid-core bamboo plywood to get thicker pieces or, for thinner ones, resaw it on the tablesaw and bring it to finished size using a wide belt sander. I do not recommend putting pieces through a thickness planer, as you will get tearout regardless of feed direction.

For joinery, I’ve used dowels, biscuits, and slip tenons. When using through-tenons, I make them from bamboo. I use Titebond Original for laminating and assembling. I treat bamboo veneer like any other veneer, cutting and taping it to obtain the right size, and using Unibond 800 glue in a vacuum bag to apply the veneer. When trimming veneers, I use a standard carbide-tipped, flush-trimming router bit. I prefer to climb cut, which minimizes the splintering.

In short, carbide works well on bamboo but steel planer blades don’t, and sanding is the best way to get surfaces with no tearout.

Other tips from out there in cyberland? Please weigh in to share your experiences and questions…

Or, made a piece with bamboo? Please post it in our gallery and tag it with the word “bamboo“.

More on Bamboo Woodworking:

- Bamboo Bikes? You Bet.

- Japan Society Displays the New Bamboo

- John Tetreault’s Bamboo Blog

- And check out our Image Gallery below:

Comments

would love to use this material for certain applications, but for a renewable material, the cost is ridiculously high, so can't justify it. better stick to less renewable local species like maple and cherry.

I would like to try the end-grain plywood. Where can I buy bamboo? And how much does it cost?

I just finished a rolling butcher block that I made from 3/4"-three ply solid core plyboo. I used traditional dado and rabbet construction. I also screwed the joints together for added support (as there was no back on the piece in my design). I hid the screw heads using wenge plugs.

The joinery worked out exactly as expected. There was some warpage when I cut the dado's on one side. As soon as you cut into the 1/8" veneer the boards bow to that side.

Everything else worked beautifully...router, sanding, finishing, drilling. Also, use a triple chip blade when cross cutting to avoid splintering.

Yes sharonlev, the expense is something to think about. And, before giving it a "green" seal of approval, you have to think about transport/fossil fuel usage as well. The bamboo flooring at my house definitely didn't come from New England where I live. But, I do like the way it looks...

I am skills trainer in furniture and cabinet making here in the Philippines. You can find bamboos of different species here in my country. If anybody wants to order I could be of help.

We have re-outfitted 8 restaurants for one client completely with bamboo plywood and paperstone. All the booths, benches and tables were constructed of these two materials. Bamboo plywood is super sturdy, and holds a mirror finish. It is as heavy as birch, though.

I have also used this material in original designs for violin stands, bedroom furniture, and bathroom furniture. The endgrain is a fun and bold decorative element.

I like it so much, I've used it for furniture in my own home. I love the smell when it is sawn or routed.

I've never used it but I've seen some nice (imported) items made from it. I don't have a project in mind but I'll give it a try in future, if any is sold in Australia.

I have had some different results than those posted above. Probably do to my methods. 6 or 7 years ago I built a dining table as a commission. I was originally going with Honduras but the ecological concerns played a role. I went with Bamboo because my supplier said they could get it for me for about the same price.

I ordered 1.5" and 3" thick slabs for my table. I was told they make the stuff in billets as large as 6" by 48" by 120". I specified NO VOIDS. Process took about 6 months from Shanghai to Long Beach harbor then by train to Chicago and truck to NW Montana. The product was NOT pristine. Quite wavy on the surface. Leading to variable thickness and there was a bit of delamination and that piece was replaced at their expense and to their shagrin.

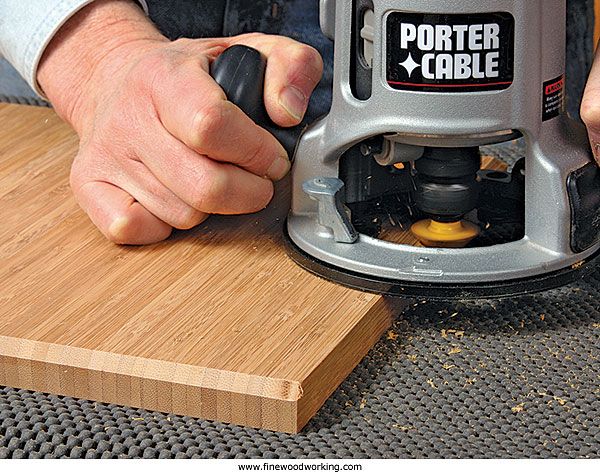

I had the slabs wide belt sanded and then I shaped my pieces by pattern routing with new large massive bits in the largest Porter Cable router. Let me say it was like butter. Hard butter, but no chip out or tear out at the nodes. Maybe a bit of burn where I had to stall the router sometimes but it hand sanded off with ease and no destruction of profile edges. I was very pleased.

I pattern routed the interior of the slabs thus producing a large planar recession that remained flat and the bowl cutting bit I used didn't tear out nodes. I removed enough material to get down to another cross layer of ply and at that point the lamination lines changed direction 90º, producing a nice graphic contrast. This was a good project and I like the material.

Wish I could post a picture or too.

After completion everyone was happy with the product but I wonder now about the eco-friendly nature of the substance. This is what sold me originally and I still like the idea of merchantable product in 5 years time but the thought of these factories (and I believe there are a lot of them) pouring their Resorcinol-laden waste waters into their river creeps me out. I also didn't like the idea of supporting the Chinese government which doesn't have such a great human rights track record.

So I concluded that it is very difficult to be politically and/or environmentally correct if one goes international.

A good friend of mine who has been in the flooring business for 20+ years told me recently that you have to be careful about calling bamboo a "green" product. Since it has become a poplar flooring product the high demand is causing the deforestation of mature forest so that it can be planted. Also, what GEide wrote above about the extra transportation and fuel usage should definitely be in the equation.

kawayan: Do people in your program use bamboo for furniture and cabinetry? If so, how? Any tips on using it?

I touristed in Malaysia recently and saw some houses at a museum that were completely made from bamboo--but they were in a really natural, rustic-style state... the flooring seemed just like round bamboo poles strung together... nothing like the engineered bamboo floor that I have in my house.

I just now posted some pics in the reader's gallery.

Took me a while to figure it out.

I've used large bamboo stalks, split in half on the bandsaw, for the trim around the doors and windows and bar top in my home theater. I'd like to use some in furniture or flooring. I hear it's very durable and does look pretty good.

I use it all the time to make pens. I use mostly sustainable materials or recycled woods in my pens at http://badgerwoodworks.com and Bamboo is one of my favorites. The cost can be high, but since my pieces are small, it's cost effective.

badger

The sustainability of bamboo products seems to depend more on who you buy it from than anything else.

Here are a couple of vendors that have good information on their websites:

EcoTimber

http://www.ecotimber.com/pledgeOverview.php

http://www.ecotimber.com/guide/eco-friendly-flooring.html

Smith & Fong

http://www.plyboo.com/plyboo-fsc-certified-bamboo-plywood-and-flooring-products.html

-Steve

Though I have yet to use the stuff personally, I know enough about to be cautious. First, the stuff is incredibly high in silicates. That's why it takes a cutting edge and can be used in place of flint or obsidian in a paleolithic culture. Those who served in the infantry in Viet Nam will corroborate me.

Second, there are enough varieties of timber bamboo that are temperate in their growth habits that importing it from Asia is unnecessary. Here in California we have grown both [i]oldhamii[/i] and [i]bambusoides[/i] for over a hundred years. Both species are hardy to below freezing.

Third. Personally, I would split before I tried to saw. The outer skin is so hard that even carbide tools will get eaten before you know it.

Lastly, IMO, the stuff lends itself ideally to bentwood styles of chairs and tables. Making it into plywood seems an odd idea unless you specifically want flooring.

I've used 3/4 bamboo ply in multiple custom projects of my own.

It's expensive upon purchase although it saves you loads of precious time as it needs no edge banding and looks amazing with rounded or chamfered edges, exposing the inner plys. All end pieces need to be taped with painters tape before any cut is made to avoid extensive tear-out.

I have utilized this renewable product for merchandise display cabinets, storage cabinets, cafe tables, bar counters, drawer re-facing etc.

I have found that for finishing I have obtained the best results with completion of hand sanding at 220, applying 3 coats of thinned Boiled Linseed Oil followed with an oil based polyurethane.

A company by the name of Cali Bamboo has 8+ options of different plys to select from and they have will-call if you live in the San Diego area.

Yes Bamboo is great for turning I made a Bamboo & plexiglass

bowl it turned nicely but I had to sharpen my tools often and is hard to sand that must be why it good in flooring

Paul Guilbeault Windsor Ont Canada

Log in or create an account to post a comment.

Sign up Log in