Dedicated Sled Delivers Perfect Finger Joints

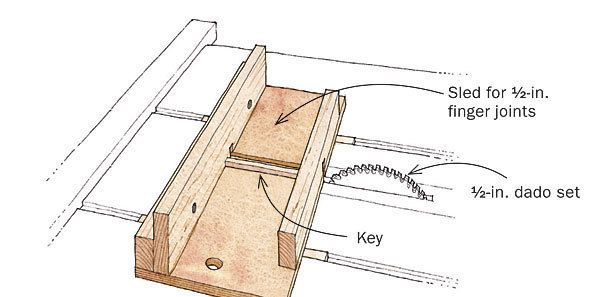

Most tablesaw jigs for cutting finger joints (also called box joints) mount to the miter gauge and must be tweaked every time they are reattached to the miter gauge. I took a different approach, making a simple sled to cut one size of fingers. The sled ensures repeatable results without tweaking, and it rides in the tablesaw’s miter slots, so it doesn’t depend on the miter gauge. It uses the same principles as a miter gauge jig, but requires far less setup on each consecutive use.

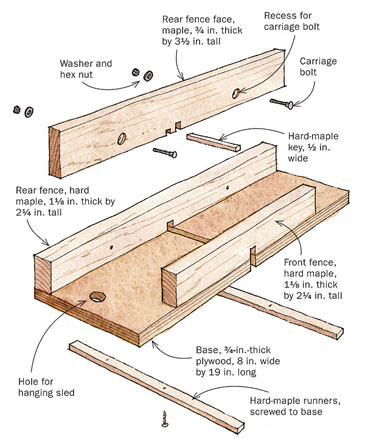

To make a sled for 1/2-in. fingers, start with a Baltic-birch plywood base. Add hard-maple runners, sized to fit the miter slots, then add front and rear fences, also made of hard maple. After assembling the sled and cutting a 1/2-in. dado slot through it, use the same dado setup to cut a notch 1/2 in. wide by 1/4 in. deep in the lower edge of the rear fence face. Don’t bolt this fence face to the rear (fixed) fence just yet.

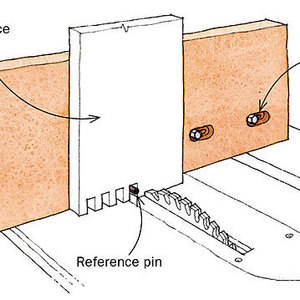

Glue a snug-fitting key in the notch and, using a scrap of the key stock as a spacer, position the fence face so the key is 1/2 in. from the slot in the base (this dimension will change if you use different size fingers). Clamp the fence face at this position, then install small recessed carriage bolts from the front of the fence face, enlarging the holes through the fixed fence slightly. Lock the fence with washers and hex nuts and cut a trial joint. If you need to adjust the setup, loosen the hex nuts slightly, tap the fence face left or right as needed, and retighten the nuts.

To use the jig, mount the appropriate dado blades, set the depth of cut to accommodate the stock thickness, and go. You can add a sacrificial backer board (1/4-in. hardboard) to reduce tearout when cutting fingers that are shorter than the slot in the fence. The 1/2-in. fingers work well for most of my needs, but if you need other sizes, make a separate jig for each size.

Drawings: Jim Richey

Additional Reading:

- Tablesaw Box-Joint Jig

- Simple Finger Joint Sled

- Router Table Box-Joint Jig

- Pinned Box Joints

- A Better Way to Build Boxes

Fine Woodworking Recommended Products

Hedgehog featherboards

Double Sided Tape

MicroJig Matchfit dovetail clamps

Comments

I believe most amateur woodworkers do not realize how much elegance and stability well-constructed box joints adds to a project. This project makes reproducible box joints simple and easy. The above plans produce a tool that--in some form or fashion--belongs in every shop. I substituted oak for maple, and not having the thicker material for the fences, I simply glued and screwed two boards together which worked just fine. I had some left over oak flooring that still had the hard finish, and narrow strips from this made excellent runners as the polyurethane finish seems to slide well in the table grooves.

It's always a grind for me to have to spend time and effort in making a jig or tool so I can construct something. This, however, was time and effort well-spent as the sled works flawlessly. I'm currently finishing up frames for bee hives, but have a list of other projects that suddenly seem more appealing.

Log in or create an account to post a comment.

Sign up Log in