How to Build Solid Drawer Bottoms

Plywood is easier, but it can leave a hollow feeling

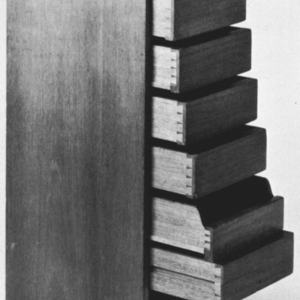

Synopsis: Garrett Hack has repaired more than a few solid-wood drawer bottoms in his day, but he hasn’t lost his enthusiasm for this construction method. Plywood might be easier, but solid wood is better and more appealing, he says. And it is not difficult to make a drawer that will last through the ages unhampered by seasonal wood movement. Here, he explains how to make a fit a basic drawer bottom and shows a few variations for large and small drawers.

Plywood is popular for drawer bottoms because it’s easy, but I think a solid bottom is better and more appealing. Solid wood is plenty strong, and it’s definitely more attractive. Solid wood is also easy to customize: You can use thicker, stiffer stock for heavy drawers, or very thin, light stock for the smallest ones. You can use a wide variety of woods, and some, like cedar, have the bonus of a wonderful aroma. Last but not least, a smoothly planed solid-wood bottom attracts far less dirt than sanded plywood.

I must admit, I’ve repaired many solid-wood drawer bottoms that were split and falling out. were the drawers overloaded, were the bottoms too thin, or was seasonal movement not considered? It’s tough to say, but building a solid-wood drawer bottom that can last through the ages is no more difficult than fitting a panel to a frame. In this article, I’ll explain how I make and fit a basic drawer bottom and show a few variations for large and small drawers.

Anticipate wood movement

When building with solid wood, it’s important to remember that a wide panel like a drawer bottom will expand and contract seasonally—as much as 1⁄8 in. with a large drawer. I deal with this movement in several ways. First off, I don’t use glue, and I bevel the edges so the bottom can float in the grooves that house it. I also run the grain from side to side. running the grain this way ensures that movement takes place from front to back, so the bottom doesn’t shrink and fall out of the grooves. By making the groove in the drawer front deeper (40% of total thickness) than in the sides, additional movement is accommodated there. Last, I use quartersawn stock, which is more stable than flatsawn material.

There are a few other important tricks: The drawer back is shorter than the sides, stopping at the top of the grooves. This allows me to slide in the bottom after the drawer box is assembled. That gives me one less part to deal with during glue-up, and makes the bottom repairable. It also gives me another chance to fine-tune the bottom or better match a curved front. on antique drawers, the bottom is usually nailed up into the back (one cause of splitting)

From Fine Woodworking #213

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Estwing Dead-Blow Mallet

Jorgensen 6 inch Bar Clamp Set, 4 Pack

Log in or create an account to post a comment.

Sign up Log in