How to Mill Lumber and Cut Parts to Size

How to turn rough lumber into straight, flat, square furniture parts

Synopsis: Learn how to mill lumber into straight, flat parts using this straightforward method explained by Stuart Lipp. By keeping organized and following a logical sequence of steps, he is able to keep all his parts organized and avoid mistakes.

At my first job in a furniture shop, I spent most of my time cutting lumber to size. I learned quickly that to make beautiful furniture, you must mill carefully. Cut a board too narrow, for example, and you no longer have bookmatched panels wide enough for your doors. Mill a piece out of square, and you could throw a whole project off kilter.

The way to avoid mistakes, I discovered, was to follow a logical sequence, and stack my boards in an orderly fashion so that there was no question about how they should be fed into the waiting machines. to make things easier as I moved from one machine to another, I started using two carts, one for the infeed side and one for the outfeed side. If you don’t have two carts, you can always use a counter or benchtop.

Flatten both faces first

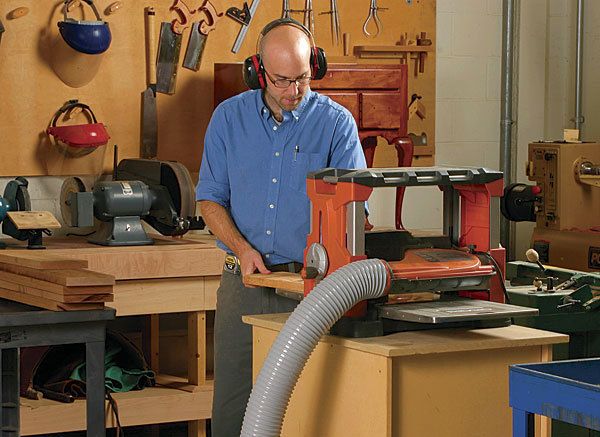

Milling a board square starts at the jointer, where you flatten one face. Then you move to the planer and plane the second face parallel to the first.

Get your boards organized before you start. Stack them so that they can be taken off the cart and fed directly into the jointer, which means the grain runs from top to bottom as it goes from the front end of the board to the back. If any boards are cupped or bowed, stack them so that the cup or bow makes a frown. The two low ends will provide a more stable base than the peak of the cup or bow. I also throw a scrap board on the stack so that I can test my machine setups as I work through the milling process.

When planing, you can reduce snipe—the tendency of the planer to cut deeper at the front and back ends of the board—by feeding the boards through so that the leading end of one touches the trailing end of the one in front of it. Before the final pass, send the scrap piece through to check that the planer is set to the correct thickness.

From Fine Woodworking #213

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Starrett 12-in. combination square

Stanley Powerlock 16-ft. tape measure

Grout float

Log in or create an account to post a comment.

Sign up Log in