Mudroom Built-In: Stop Clutter at the Door

Learn the fundamentals of built-in furniture with this stylish storage unit

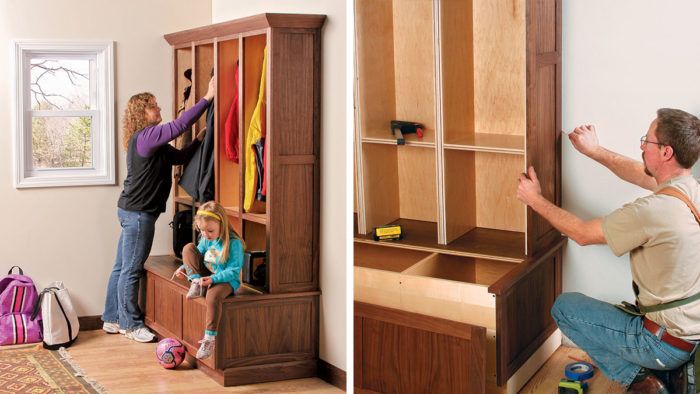

Synopsis: This mudroom unit features a base cabinet topped with open locker-type cabinets. The base cabinet has a lift-lid section for stowing out-of-season items like winter boots. The upper cabinets have fixed shelves and hooks for jackets. The construction is simple: maple plywood cases with walnut face frames and applied frame-and-panel assemblies. Most of the piece can be constructed in the shop and assembled on site for a built-in unit that will not only look good and organize your life, but can also add value to your home.

An enclosed porch or mudroom can help keep dirt and snow from reaching the living areas of your house. It’s also a great place to stow stuff you’d rather not have cluttering the kitchen or family room: boots, shoes, book bags, sports gear, and the like. But without designated storage areas, a mudroom becomes a minefield. An elegant solution is to make a built-in storage cabinet, which will not only look good and organize your life, but can also add value to your home.

This mudroom unit features a base cabinet topped with open locker-type cabinets. The base cabinet has a lift-lid section for stowing out-of-season stuff like winter boots. The upper cabinets have fixed shelves and hooks for jackets. This piece is designed for a family of four—with each person getting his or her own locker space—but it can easily be made larger or smaller to suit a different-size family.

The construction is simple: maple plywood cases with walnut face frames and applied frame-and-panel assemblies, which give the piece a furniture feel. Most of the parts are made in the shop and assembled on site.

Build the plywood boxes first

For this project, I used prefinished 3⁄4-in.- thick maple plywood for all the cases. Though not commonly available at major home centers, the plywood often can be special-ordered at lumberyards. It saves you considerable finishing time, and creates a bright, durable interior that looks great with the dark walnut exterior.

For the upper lockers, I made four identical skinny cabinets and screwed them together. These smaller cabinets are easier to build, move around in the shop, and install. And this method can make the difference between needing a helper and getting the job done on your own. The plywood edges on the upper lockers are hidden with solid-walnut face frames, which are glued and nailed in place. To help align the face frames, I used 1⁄8-in.-thick splines cut from tempered Masonite. Before assembling the cases, I cut the grooves for the splines in all the front edges using a router and a slotcutting bit. To assemble the cases, I used screws and biscuits.

From Fine Woodworking #213

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in