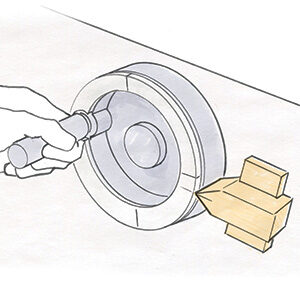

No-fuss jig dials in caliper settings while turning

Any turner will tell you that turning a spindle requires lots of caliper settings. To ease this process, I came up with this double-duty V-gauge.

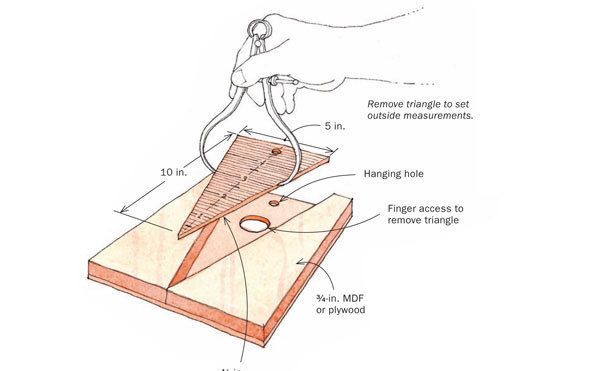

To make the gauge, cut an isosceles triangle (10 in. tall with a 5-in. base) from 1/4-in.-thick hardboard. Rest the triangle on another piece of 1/4-in.-thick hardboard, and glue and nail two 3/4-in.-thick scrap strips of MDF or plywood, one on each side of the triangle. After the glue dries, cut the gauge to the rectangular shape, as shown.

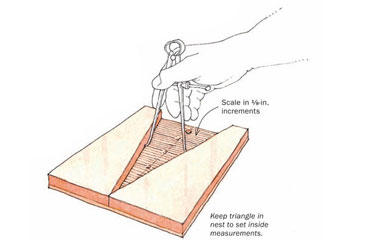

Next, draw lines across the triangle to designate different widths in steps of 1/8 in. If you’ve done everything right, these lines will be 1/4 in. apart.

When the triangle is in its nest, I use the jig to calibrate for inside measurements against the 3/4-in. edges. When the triangle is out of the nest, I use it to calibrate outside measurements. You can use the lines for even 1/8-in. settings or eyeball between the lines for 1/16-in. or even 1/32-in. accuracy.

Drawings: Jim Richey

Fine Woodworking Recommended Products

MicroJig Matchfit dovetail clamps

Incra Miter 1000HD

Woodriver Circle Cutting Jig

Log in or create an account to post a comment.

Sign up Log in