Q:

Ed Pirnik, Stamford, CT

A:

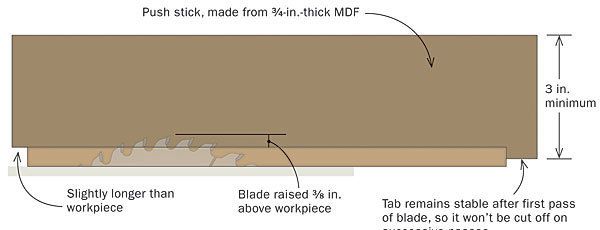

With the right push stick, it’s a safe cut. Make the push stick from a piece of 3/4-in.-thick MDF that is at least 3 in. wide and a little longer than the board being ripped. The length of the push stick makes it easy to hold the entire strip down as it passes the blade. Its width buries the blade in the push stick and keeps your hands far from the blade.

A tab on the back pushes the stock.To make it, cut a notch on one edge that is just shallower than your stock is hick and not quite as long as the push stick. After you rip the first narrow strip, a thin tab is left on the inside of the push stick. Here’s the reason for making the push stick from MDF: The tab on a plywood stick would curl up and be cut off on the second pass, but the tab on an MDF stick will not curl.

You also should use a thin-kerf blade and a zero-clearance insert with a riving knife or stub splitter. Set the blade about 3/8 in. above the stock and keep the splitter lower than the blade.

Photos: staff; drawing: Kelly J. Dunton

Fine Woodworking Recommended Products

Milescraft 4007 6in Bench Clamp

Woodriver Circle Cutting Jig

Double Sided Tape

Log in or create an account to post a comment.

Sign up Log in