What's wrong with this picture? Plenty! Identify these woodworking no-no's in our new game, Against the Grain. Check out our first edition: crosscutting on the tablesaw.

Welcome to the second edition of Against the Grain, a brand-new game from FineWoodworking.com. ATG is meant to teach up-and-coming woodworkers some valuable lessons on safety and technique. For those more-seasoned wood rats, we hope to help you brush up on your skills and remind you of methods that will help you to work safer and keep all your digits intact!

Against the Grain: Dozuki Disaster

This woodworker proclaims himself to be a dovetail master. But to anyone skilled enough to know the difference between a dozuki and a gentleman’s saw, he’s got a few things to learn. Help identify the five woodworking no-no’s in this photograph before he embarrasses himself in front of his shop buddies!

Play Past Games

Comments

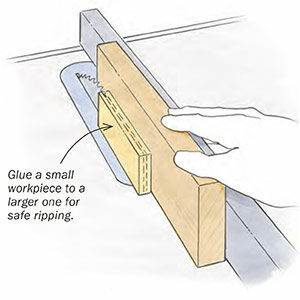

For another game of "Against the Grain" I hope you include a rip-cut hazard. Probably a basic "no-brainer" safety rule, but frankly I've never seen it in print..............NEVER MAKE A RIP CUT WITH THE BLADE TIPPED LESS THAN 90 DEGREES TOWARD THE FENCE. This makes a deliberate pinch-point for the rear of the blade to easily grab the workpiece and throw it, mangle it, or worse yet........give your pushing hand the sudden freedom it needs to lurch directly into the blade. I have a nasty scar on my ring finger to attest to this hazard!

Thanks for the suggestion Cadabara. -Gina

How about that wedding ring? That was what I clicked first, though it was not correct. De-Gloving a finger is a nasty sight.

I like this! However, *how* to play the game is NOT intuitive. Some instruction on how to find the mistakes would be beneficial.

I like this! Also would like to see more great tips!

I find it amusing that the game showed all five mistakes that Mr.Osorio made with his table saw in the Riobi lawsuit and your picture showed a "sawstop" fence on the table saw

BillV

Six, I make it. The sawblade has no guard.

It would have been nice if the "sleeve" issue had a better range where the choice could be selected. I picked the wrong spot three times. Otherwise, pretty cool.

I heartily agree with Tim Nott. The lack of a guard seems like a terrible hazard, maybe worse than all the rest.

It is a shame that YOU miss the most obvious mistake - buying / using a saw without a crown guard.

Great game! It only took me seven clicks, the five identified plus the ring and missing guard. Thank God I still have all ten digits and no serious scars after working around machinery for 50 years.

WHY SHOW SAW WITH OUT THE BLADE GUARD IN-PLACE

O.K. pretty simple. Got them all on the first try. 5 for 5. :D

When I first saw the image... I got this freaky scary feeling in the pit of my stomach. I've seen people do things like that before and the results can be devastating.

I am assuming that this was "set up" for the "fun of it" and was not a shot of this actually happening?!

It's always good to remind, some of us, of the stupid things that are sometimes done in one's shop... most often because we want to save time and "get 'er done fast", at the possible expense of our personal safety. You know, fingers, arms, eyes and the occasional piece of wood shot back through the kidney. Hey, I have more than one of each of those anyway -- so what the heck. ;-)

Thanks Fine Woodworking, for reminding ME about safety @ the Table Saw.

BTW: Even the new SawStop saw can't help in that situation.

I agree with KW193cox about the ring - I added extra points to KW's and my score.

I'm amused with BillVan, but for another reason than the Ryobi lawsuit. I can't remember ever seeing anyone woodworking in a starched, long sleeve, white dress shirt.

I'm sure that this will get me a boat load of negative comments, but I feel pretty strong about it. I've been a professional woodworker for 40 years, still have all my digits. I've found that any blade guard installed on a table saw creates more of a hazard than helps to stop one. They block your visibility and our just plain in the way. On the quiz, got it in 5 clicks.

I'm feeling pretty good. Got all five right off the bat, and I don't even have a tablesaw in my shop.

Got it in 5....as to the blade guard,I spent the last 6 years of working life as a H&s rep and I aGREE WITH MOST WOODWORKERS THAT A BLADE GUARD IS A HAZARD. i FOUND THAT i CANNOT SEE PROPERLY TO DO THE JOB.i WONDER WHAT THE AVERAGE WOODY THINKS OF A BLADE GUARD?

Congratulations FW on devising a simple, instructional and hopefully motivational tool to teach woodies safe workshop practices.

I hope to see many more.

Where's the guard?

Too bad the Sawstop table saw can't sense the idiot and keep the saw from starting in the first place. Hey, what a great idea! They could call it Sawstart or Sawsmart. It could give you an interactive test to see if you have the brains to operate the saw in the first place. If you don't pass the test it's back to the drawing board.

Sure beats waiting until the accident happens and then wondering what you did wrong when the saw jambs up to save your ass.

It sure could have saved Ryobi a lot of grief. They could have used the technology on the jurors as a prerequisite to testify.

I've always managed to stay safe by having a lot of respect for machinery. Keep it fine tuned and respect it. Every board and situation is different. Listen to the machine and the sound it makes as you cut. Have a preplan. NEVER GET COMFORTABLE. If you feel for a second that what you're doing is going to compromise your safety, it's time to STOP and reevaluate. I think I read that someplece in Fine Woodworking years ago. Kian - don't feel bad, I don't believe in using a guard either.

Did not even think about the guard. Like some of the posts above, have not used one since I do not remember. Just need to remember to keep your fingers away from spinning sharp things!

Where's the blade guard? Also, should not be wearing jewelry (wedding ring).

People this stupid should not be allowed to use power tools. Likely scenario: He will cut off a finger then sue the manufacturer for negligence.

What happened to the blade guard?

this is an excellent teaching tool, and hope this and other future safety games will be posted and linked for some time.

I run a crew of volunteers. I have 7 skilled finish carpenters as part of the crew, and 30 that run from "I can't read a tape" to "I work on my own home".

This will be a excellent introduction for them to reinforce what we are teaching them hands on. They all have to go through general safety program before they can even be allowed on our projects, and this will help provide something more specific to the trade.

Lets have more - from 'no brainer' level on up!

Same here. I pointed at the ring and the blade guard. I know sometimes they say it's ok to not use the guard, but I wasn't sure on this type of cut.

Great teaching aid. I found all five items easily, but can see where newbies to woodworking may only see 1 or 2 of them.

I also feel that no jewelry of any type should be worn when using power tools. I now own a SawStop Professional for the added safety of it. The table saw is a very dangerous tool if used wrong. Stay safe out there.

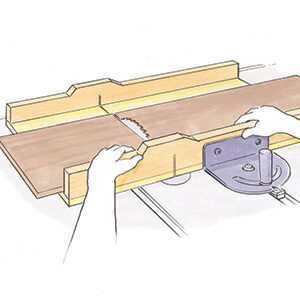

I'm surprised that no one suggested using a cross cut sled, I almost always use one to cross cut on the table saw.

Great reminder! Superb idea! We all have a tendency sometime to start our machinery before our brain kick-in. Got the five identified easily, but like other, I expected the ring... and missing guard.

Like many, I don't use the guard all the time, and don't feel it is such a hazard. In my opinion not using a stop block, the height of the blade combined with the loose sleeves are the major hazards here.

The reason there is no guard is to show the blade for demo purposes. There should be a guard. Also, this machine is a Sawstop which will detect human flesh and almost instantaneously arrest the blade and lower it underneath the top. There will only be a slight cut, but I think the blade gets trashed. Yea, there should be a guard in this picture. Data show that when guards are used on table saws, people don't lose their fingers.

Very good. These tests should be featured for all power, and some hand, tools on a consistent basis

A good learning tool, but the saw in use will protect careless, incompetent people from injury won't it? That is want we as a society want in our lives - risk free living regardless of our competence.

As with seat belts and air bags, the tool will become the primary line of defence not the brain.

Don

Got the same "seven" others have posted, plus one:

Wearing a dress shirt while working in your woodshop in the first place should generate immediate revocation of manhood and a bolt of lighting through the roof.

TimNott and others correctly pointed out the lack of a guard. That's what we call here, an editorial oversite. The guards are generally removed for visual clarity but you folks raise and excellent point and I think it's worth including a notation beneath the image stating: "Blade guard has been removed for clarity." A good catch that keeps me humble!

As for the wedding ring, I walked around the office to take a poll on that point. Most folks agreed that the ring point is more a matter of personal preference. That said, raising all these many points is in part, the point of the game. I make folks go to the blog post so that they can access the comments after playing, and read all the additional tidbits of information we get from our readers. So keep 'em coming - and thank you!

Cheers all and thanks for playing. By the way - this was staged - as I think it'd be hard to grab a photo of anyone that crazy. The hands do belong to one of our staffers though! Ha ha ha.

And as for that starched white dress shirt - too funny. Since I shot this in the summer - nobody at the office had long sleeves on, and the only shirt I could dig up out of our storage closet was a long sleeve, white FWW button down. Actually, we all made the same jokes about woodworking in a dress shirt, here at the office.

Best,

Ed

A great idea for safety, both as a reminder, and a prompt for beginers. I have a small destroyed stain can suspended above my table saw as a reminder never to even move items way above a moving blade. I accidently dropped this can. and then me, my saw and a lot of my shop had a dark minwax stain, and I hadf never seen a can opened and emptied so quickly!

I also noticed no blade gaurd, and the ring on the finger.

David Yates

I've been making a living as a carpenter for several years now, and count myself lucky to have only had one "incident"- a shim kicked back in the 'nads at 120 mph. That leads to my first point, that some line of fire mention could have been included in the game.I'd also like to point out that an omission (imho) is to solve the problem you intentionally created by photographing the workpiece tight between the blade and the fence - as a measuring stop for repetitive cross cuts. Most professionals know that the simple solution is to clamp a block to the fence closer to the operator and away from the blade. That gives you something to measure off, but allows clearance by the time the workpiece is slid to the blade.

A point about awareness of danger. Years ago when I worked as a farmhand here in Canada, the farm safety association printed off stickers that said - "Be careful. We love you. Your family.", that you were supposed to stick near your your pto or other potential hazards. Might be a bit sentimental, but is there anything like that out that for us? I keep the shim that sacked me on the dashboard of my truck, and had a little drawing by my daughter. However, the drawing faded, and I hardly notice the shim anymore. Maybe I need to ask for another little picture...

Finally, let's get a REALLY active debate happening about guards here. Most of our saws came with those poorly aligned splitters with spring loaded fingers that, in this instance, would jam up after the first cut. The saw in my cabinet shop has a home made, always evolving overhead guard/dust collector. Alas, my jobsite Bosch has no such luxury. What do other people do? I'd love to see other woodworkers overhead guard attachment solutions.

bobinboerne: I shall immediately raise the issue of your "revocation" with the model. He will be crushed, for sure! Ha ha

-Ed

Although i'm pretty sure that most of us could easily get these 5, many asked about the blade guard. I worked for 14 years in an upscale cabinet shop in Las Vegas and there was no blade guard to be found on any of the 3 Unisaws we had...i was taught without one, and always felt they always got in the way of production work & I always want to see the line of cut clearly....just my 2 cents. By the way, of all the cabinet shops I've been in i cant recall more than 1 or 2 that employ the blade guard with any regularity...

Be safe all - no second chances!

I'm also not sure why you'd have the riving knife in place when you're making cross cuts. Ripping yes, but cross cut?

I'm also not sure why you'd have the riving knife in place when you're making cross cuts. Ripping yes, but cross cuts?

I'm also not sure why you'd have the riving knife/splitter in place when you're making cross cuts. Ripping yes, but cross cuts? I also clicked on the ring.

Great Safety Review Thanks

greywolf6: I hear you. Most folks I've encountered find the blade guard to be a major hinderance to seeing their cut. Heck, I've seen very few cabinet shops with them in use. That said, it is perhaps one of the best ways to keep those precious fingers intact. Well, that AND a little dose of fear. I still fear the tablesaw and I find that the emotion keeps me much safer in the long run. I treat the tool with the same respect I did when I made my first cut many years ago and as a result - I've never had a single accident. Not even close.

Best,

Ed

Great tips, particularly for the beginner. Aren't there six no-nos...a bladeguard? Mike from Nashville.

I can't believe they convinced someone to pose for this photo with the blade running.

Honestly, the only part of this picture that makes me cringe is the cross-cutting with miter and fence... all I can see when I look at that is the cut-off flying up at the user's head with 3-HP worth of conviction. I literally can't look at the picture any more.

I don't turn on my saw without safety glasses on. As I get older, I put on ear protection too. If its a lot of cutting like ripping rough stock, add a respirator and I turn on my overhead dust collector. I want my body to last a long time.

I like the concept of this quiz, but the clicking is not very intuitive. I got all five errors, but I was clicking on something else in some cases - for instance, I clicked on the ring and the sleeve issue came up. The interface needs to be improved.

About the ring, by the way, it's NEVER a good idea to wear jewelry of any kind (I dunno, maybe non-dangly earrings?) while woodworking. You NEVER know how they might interact with what you're doing. I recently (while lifting a too-heavy log for splitting) dislocated my ring finger. If I had been wearing my wedding ring, I would have had to had the ring cut off, and possibly could have lost the finger, given how it swelled up. I wear little (ring, watch) but take it all off when in the shop.

TMitchell: Yup - that's the one that always makes the hair on the back of my neck stand up as well - yet I've seen people do it many times. We had to get pretty creative to pull it off safely for the photo.

Best,

Ed

What a great service to the woodworking community. It's a good reminder for the serious woodworker that may get a little sloppy over time and a real limb-saver for the newbie. Safety must prevail in the workshop so that we may all enjoy this unique craft.

I agree it's a good quiz. However I was surprised that the fact there was no blade guard in place was not included as a no no.

The quantity of comments is a good indicator of the benefits of such discussion, even if they are only a reminder of what we already know and should be practicing on a regular basis.

I'll admit to not having either a guard or a splitter. The stock splitter proved worthless in use; when tension was released and the stock started to pinch, the splitter didn't do much. I've had better luck stopping the cut, shutting off the saw (color coded switch location on the fence rail, so no fumbling) and putting a small wedge in the kerf.

As for the lack of a guard -- this could be debated forever. I'm the only one that uses my saw, so my situation might be different from a shop where several people share the saw. I make it a point to rehearse every cut, however briefly -- how will I start the cut, how will I move the stock past the blade (do I need a push stick?), can I anchor my hand on the fence such that I can move the stock safely past the blade, etc. -- before I make the cut. If nothing else, it gets me focused on the task (and the danger) before I turn the power on.

Safety is between the ears, but constant reminders are a good idea.

--

Mark

Wearing Jewelry, even the 'tight fitting' ring, can be dangerous.

Bill

I also thought about the ring. But the most glaring problem was, where was the guard? I have been woodworking for about 39 years and yes I still have all my fingers. The one consistent thing I have seen when I have visited both commercial shops and private shops is that almost everyone removes the guard. The excuse is that you cannot see the cut. Frankly if you have a good fence and your saw is aligned correctly the cut will be as you set it up to be. I have a delta contractors saw with the unisaw fence once I set up the saw I always set an additional 1 thirty second over size and take it to the jointer which I always keep at this setting and I have a perfect cut. The cover is always on the saw unless of course you are doing a cut like a cross cut or one that is not all the way thru the work-piece such as a dado cut. I made my own blade guard from a floor sweep that came with a shop vac. The guard is mounted on a trapezoid suspended from the ceiling above the saw the combination of this hooked up to a shop vac and the shop dust collector keeps me from being hit in the face with saw dust not to mention keeping my hands away from the blade. By the way I sent pictures of this to methods of work a few years ago but hey have not published them.

Excellent 'game', except it's not a game. I've had two kickbacks in over twenty five years of woodworking. One was recently when I lost concentration for a fraction of a second. A good reminder of safety, safety, safety. Thanks, send us another quiz, might save someone's fingers or an eye.

Bill Maher

These were a no-brainer. If all of these were not instantly obvious to you, stop and reflect on your interpretation of table saw safety. Hope we all got a perfect score.

Thanks for a worthwhile game that reminds us all about safety issues on our equipment. Even while practicing all safety precautions, things can happen. when a mere 2"x2" triangle of douglas fir flew off my blade and hit me in the face if felt as if a mule had kicked me in the jaw. Always wear eye and/or face protection!

A 7th danger is the miter gauge. A sled is much safer and will make for much more accurate cuts.

Make a sled for 90-degree cuts, 45-degree cuts, and any special angles that are used regularly. A small sled to complete special cuts can be made of cut-offs in less than an hour, and it will save hours of frustration.

Overall though, again Fine Woodworking comes though with a great service to its readers, in fact all woodworkers [and tool manufacturers], once again.

Years ago I stuck my hand into my tractor's fan blade. By the time I pulled it out, cursed and looked at it, the finger was so swollen that I had to immediately cut off my wedding ring. I have since stuck my hand into the same fan blade...but not wearing a ring!!! I'm no dummy! The point is, there are many potential owies on all power tools and we do sometimes make the same mistake more than once, so maybe the best policy is to figure that an accident can happen to anyone at any time and so we should always be prepared for the one that hasn't happened yet. Emergency phone number posted, First Aid kit on wall next to fire extinguisher, wife, kid or neighbor aware that we are out there fiddling with tools again, etc.

I took a job at one of the large homecenters during layoffs and was amazed that more customers were not missing parts of their body. They do not want to listen to a guy in an orange apron with 35 years in the carpentry business with all of his fingers and both eyes explain why they need to buy safety goggles and read the manual before they start.

Regarding jewelry... I certainly noticed the ring, but for reasons other than ordinarily found in a wood shop. In college I spent a delightful summer working in a full machine shop, and I heard more scary stories than woodworkers tell. Hand smashed in a die press on a guy's first day at work, not using the wrist straps. Being casual with a circular saw with a carbide blade cutting aluminum plate, having it jump, and opening the miscreant's abdomen; "I've killed myself!" he said, and he was right. But the welders told of a guy whose jealous wife insisted he wear his wedding ring. One day he caught it between electrode and ground, and it flashed to white hot in an instant. As he shook his hand the ring slid down the finger, stripping all the skin off the finger along the way. We woodworkers must be careful -- I've jammed a thumb owing to a poor molding-head cutter setup, and I've been stitched up once from a kickback -- but we do have a somewhat limited set of ways to damage ourselves.

Richard Juday

Many people have mentioned the question of a blade guard, but not many have put all the pieces together: most woodworkers remove their blade guards, because the blade guards are terrible! The manufacturers know this, and have been ignoring the protests and complaints for sixty years or more. Power tool manufacturers should be embarrassed that they haven't improved guard designs in all that time.

Few people use blade guards, because most of us know that the standard guards offer only the illusion of safety. Aftermarket guards are only a bit better. It's easy to parrot, "Use the guard and you will be safe", but that's only true if you carefully choreograph your intended accidents. Standard guards will stop a few accidents, and cause a bunch of others, while slowing production to a crawl.

I like the game that editor Ed Pirnik has offered us. But I'm disappointed by his cop-out in the comments. He brings out the standard magazine line, 'I think it's worth including a notation beneath the image stating: "Blade guard has been removed for clarity."' Please, Ed, don't be another stooge for bad design. Tell the truth. The blade guard has been removed, because it is lousy, and is never used. At least that is the truth for 90% of your readers.

I'd like to see FWW be honest and forthright about the problem, and pushing for better guard designs. How about a notation beneath every image that says, "Blade guard has been removed because it sucks!" Or if you must, "because it impedes production and causes as many safety problems as it solves." In either case, I dream of a caption on every table saw photo that says, "Manufacturers, you've contributed to this safety problem for over sixty years. When are you going to contribute an effective design improvement?"

I bet if Fine Woodworking had put that note under every tablesaw picture over the last thirty years, guards would have improved. Why not start now?

I think this is becoming a competition for who has the nastiest story. OK, I'm in:

Years ago when I was working as a timber-frame carpenter in rural Connecticut, I worked with a trim carpenter who wore blue rubber caps on two of his fingers in order to cover some insightly stumps. One afternoon, I just couldn't help it - I asked him "what happened?"

Apparently, he was working on a job one day, jointing some trim stock on his machine, set up in the driveway when a pretty woman walked by. You know the rest of the story. He turned his head and kept on going with the cut - the cutterhead chewed up two fingers. Always keep your eyes on your hands and your blade/bit! Sheesh!

He still swears she was worth it though. Ha ha ha

Best,

-Ed

I worked for several years as a machinist. I saw some pretty horrific accidents which generally resulted in the loss of part or all of a finger or hand. I managed to get out without any machine based accidents, mainly because I was scared to death of the machines, which meant that I never took one, or the safety devices for granted. The first thing the forman told me on my first day was that machines have no brains; they will cut through, drill through, and punch through anything that is put into their path. It has no way of determining (until Sawstop of course) whether the work piece is wood, metal or flesh. I always kept that in mind, and I still do in my own workshop. The one potentially disasterous accident I had there was not machinery involved. A pile of steel collasped on me. I came out fine thanks to safety equipment I was wearing.

I quit wearing jewelry after seeing a guy pop his wedding ring finger off on the shop floor.... he swung down from a platform. There was a pop rivit on the rail that caught his ring and the weight of his body did the rest. I have since seen people crush their rings, catch bracelets, and one guy pull off most of his ear on a drill press. don't wear anything that might get caught up in the machinery!

It's great to see so many people arguing for blade guards. I am on my third. The original equipment on my Ryobi 3000 was useless. I bought an Exaktor which was only marginally better. It was useless when ripping a narrow piece of wood -- the fence got in the way of the guard. Actually it was always in the way, and hard to see through. So I saved the top half (the dust collection part) and attached one of Lee Styron's custom made guards to it. It's not perfect, but it works a LOT better than anything else I've tried. (Google Lee, or contact [email protected]).

Once a few years ago, I was cutting a 3 or 4 inch slice off of a piece of 1/2 inch plywood. I don't know where my mind was, but I got it just about an 1/8 inch off proper direction, and the larger piece came back at me at about 300 miles per hour with a slightly ragged bottom edge which caught me on the underside of the right forearm which ended up looking roughly like hamburger. Thank heavens the guy on duty at the emergency room was a real craftsman. He sewed me up with about 40 stitches and now it just looks like, well, white hamburger. That nice young man gave me the surgical kit as well -- scissors, scalpel, a few tweezers, a hemostat and a few other odds and ends (he would otherwise have thrown them away). That was the only good part of the story. The guard, the kickback pawls, the dust collection. . . They may be a pain, but it's the right kind of pain.

I also saw and pondered the ring. I don't take mine off when I work. I think I'm going to start doing so. This was a very useful discussion for me. Thanks FWW.

By the way, to see my version of the crosscut gauge several others have mentioned, look at the Jigs section of "Gallery" or use this url:

https://www.finewoodworking.com/item/26315/crosscut-gauge

Very simple, very effective. I cut it exactly 1 inch wide which means I can still use the measuring system for the fence; just subtract 1 inch, and you are right on. Unfortunately, the pic was taken before I finished my Styron blade guard.

Good ones, especially the unbuttoned sleeves. I'm sure we have all had pieces of wood come flying back or around the shop by NOT clearing the out-feed side of the table. Fortunately, most of us learned from our mistakes before real damage occurred. Ruined wood is far cheaper than mangled fingers or holes punched into your body!

Excellent way to bring safety issues to the forefront! One thing does have me puzzled, though: how did all of those cut-offs make it that far past the blade with such a short fence? I'm guessing that part must have been set up, because there is nothing there to push the parts through.

I still use a 1950s Rockwell Delta contractor-style table saw that has (had!) a horrible guard. I haven't used the guard in years, because I can't see a thing with it mounted. I was later taught to leave the guard off, think about what I'm doing, and be careful. That instructor -a professional woodworker with years of experience- has since come close to losing half of his hand.

Another point about the ring: I learned over fifty years ago to leave the jewelry at the shop door. I worked in a gas station while going through college, and saw a very experienced mechanic lose his ring finger when the ring made a connection between a battery terminal and a grounded component under the hood.

There are more than five things wrong. He should not have his wedding ring on. Like the long sleeves, it can drag him even further into the blade if there is an accidental contact.

A good quiz.

Manufacturers have lots of excuses for why they can't design a good guard in part because they can't anticipate every jig etc. we might come up with. But that is no excuse for not really trying. Publications have a responsibility to lead by example. Shoot a small photo insert to show why the guard makes it impossible to see what you are doing. Or, a simple honest statment why the guard would not protect in this particular operation. Eventually the makers would pay attention.

However the key here is to remember we all make safety mistakes and hopefully learn without injury.

I have a Sign on my shop door I see when I enter the shop.

SAFETY

Remember to think safety and be safe. You have already used up 8 of your 9 lives.

get rid of the ring for #6, also he is running the material through the wrong way since there is more tearout on the backside when there is a rabbet or trough groove for #7

Cool game, one more thing that might be an issue is that there is an item on the left side of the picture that looks like his safety glases, but since we can't see the face can't say for sure if he is wearing any.

Yes!! 100% and I was able to type this with all TEN fingers.

Set rules for your self when using ALL wood working tools and NEVER compromise your rules.

Great beginning to a new and very important game! Safety is everything, take it from a guy who tried to bypass it for "one last cut" and nearly lost two fingers. Still have both fingers but at only about 80% use. Can't make a complete fist and hard to maneuver small hardware around. I'm working in my shop more than ever and still find myself thinking about taking a shortcut, but intelligent enough to look at the picture of my once sutured and ravaged fingers I have taped to my tablesaw headstock. Great reminder of what can happen, no matter how long you have enjoyed this craft, when you lose the Safety Attidude. Your (grand)kids will enjoy all those toys and projects, but I'm sure they would trade any of them to be able to walk with (Grand)Dad through the woods holding a complete hand. Sound a little rough? Good, it almost happened to me and if this encourages any of you to think before committing an unsafe act then I guess it helps me live with it. Have a Safe and Enjoyable Woodworking Day!!!

Sorry I missed a point in my comments earlier. The single most important item is the splitter or riving knife. Even if you insist on removing the guard at least use the splitter or better yet a riving knife.

100%. Good start. This one was easy and informative. Agree with so many others regarding the ring. What I'd like to see for here and at Fine Homebuilding, where you have the excellent inspector series, is how about a button which leads to the answers. We don't all always get them all correct and would be enlightening to see the one(s) missed. Excellent beginning, thank you.

100%. Good start. This one was easy and informative. Agree with so many others regarding the ring. What I'd like to see for here and at Fine Homebuilding, where you have the excellent inspector series, is how about a button which leads to the answers. We don't all always get them all correct and would be enlightening to see the one(s) missed. Excellent beginning, thank you.

100%. Good start. This one was easy and informative. Agree with so many others regarding the ring. What I'd like to see for here and at Fine Homebuilding, where you have the excellent inspector series, is how about a button which leads to the answers. We don't all always get them all correct and would be enlightening to see the one(s) missed. Excellent beginning, thank you.

After I committed a serious no-no myself last October, (I reached across a still spinning blade to clear some debris.) and ended up with 17 stiches along the side of my thumb. I am lucky to still have my thumb. My very first thought, even before checking my injury, was, "You dummy, you know better than that." I no longer care what needs to get done on the saw. As long as that blade is going round and round, my hands stay out of the way. Of course, unlike the person in your picture, I was not using a Sawstop saw. Maybe I should sue Craftsman. (Kidding!!!)

Keep the safety tips coming. We all need them

Many,many years ago I used my fence on a triton workcentre to make a cross cut on a piece of 2x4 , the offcut jammed between the saw blade and the fence , skewed the saw so bad the blade chewed into the table badly , scared the hell out of me.

I have'nt done it again.

Lucky for me that one of the first shops I worked in the "foreman" ( I use the term loosely, as he was down to three, man...) was missing several fingers on his left hand, lost while talking to someone while pushing a piece through a table saw..........As a guitarist I can firmly avow that NOTHING gets your attention like seeing someone like that!!

It certainly did affect my self-preservation sense of concentration, though. Several shops later I was at the table saw one day and was handed a narrow piece of oak to trim.

Unbeknownst to me there was a small brad embedded that the worker failed to mention, and while ripping the piece the blunt end of the brad came shooting out and embedded itself in the crook of my right elbow, while I was still finishing the rip.

I only flinched, though, finished the cut and shut off the saw. I walked over to the worker who handed me the piece and let him have it with the proof plain to see.

Never a dull moment, so to speak.

HE

I teach my kids safety by telling them (in addition to correct usage practices) the saw's job is to cut off fingers. The way to keep it from doing that is to keep some wood between you and it. They think twice about how to approach a spinning blade!

I would like to see a crown guard over the blade but perhaps you removed it in order to get a clearer picture of those other bad practices

Andrew

I would add one thing. Never let round handle chisels lying on the table where it could fall on your feet. It's almost sure it will roll off the bench and if not on your feet, you'll need to re-sharpen it.

(1) I'm confused .... are the comments referring to 2 different games - 1 on table saws, 1 on dovetails?

(2) I really like the additional points given in the comments!

(3) I decided I don't want an 'escape' button. The points don't really count, and mousing around forces me to think about what I could have missed. Frustrating by instructive.

(4) The loose shirttail bothers me even in the hand sawing game -- I prefer good habits in the shop, and loose clothing leads to unexpected problems even when not using power tools.

I think there is a sixth error in the dovetail quiz. He seems to have a half tail at the end. Shouldn't the joint start and end with a half pin?

@Andy_B:

Yes, the comments are from two (so far) quizzes. It's the same problem that the FHB "Inspector" games have. I would hope that Tauton could figure out how to have dedicated comments for each game. Someday.

As a teacher what about the biggest safety rule!!!

NO EYE PROTECTION!!!

Hi ColinL: Yes, you are correct - and that's one of the five listed errors.

Best,

Ed

Ed,

I see two marking errors on the right hand side. The joint does not end in a pin, and a pin is shaded as waste even though further on, tails are shaded as waste. Does this not mean there are 6 errors?

Colin

Colin

I truly think you guys missed the most important safety no-no as Norm always said DON'T FORGET SAFETY GLASSES what do you think.

agree - ring and safety glasses are missing

CHECK OUT RODRIGREZ FIVE MIN PRACTICE DOVETAIL VIDEO>>HE USES A MORTICE CHISEL!!!!!!FOR DOVETAILS??????????????

Remember, there is no more important safety rule, than to wear these, your safety glasses.

You shame Norm and everything the New Yankee Workshop stands for... I don't know how you can sleep at night.

i really don't think that wearing eye protection during cutting dovetails is an issue. I have tried putting "these safety glasses" while cutting pins and tails and every time I do that I miss my lines. I guess I'm better without those for dovetailing joints.

I wear safety prescription glasses. I have several pair of "over your glasses or bare face" safety glasses in my shop for visitors. EVERYONE were's them or leaves. I also have hearing protection for power tool usage. THAT is just a foundation for safety. It's the ante in the poker game of not having an accident.

Of course I can spell when not distracted. I meant to type "Everybody WEARS them , or leaves the shop. Duh...

Blah,blah blah,blah blah,blah,blah.

I got all 5 and never thought about the absence of a guard, never used one.One thing I'd like to mention as something to consider is ripping on the saw. I once viewed a safety video that suggested raising the blade as high as it would go when ripping because the force of the blade is pressing the work down on the saw table as opposed to a low adjustment has more force pushing the work toward you increasing the chance of a kickback. Maybe a guard should be used in this case.

A good exercise

@Wilburpan: Same here man!

I too often see people hunched over when working. Stand up straighter, relax, breathe. All this will reduce muscle strain, exhaustion, sore back and neck. and make for better work!

Log in or create an account to post a comment.

Sign up Log in