CNC is Knocking on Your Shop Door. Will You Answer?

CNCShark from Rockler.

We’ve been keeping our eyes on CNC machines for some time, waiting to see when one would be introduced that is sized for a small shop. We’ve also been wondering what they would be used for in a small shop. After all, your average hobbyist or custom furniture professional doesn’t need to mill a ton of parts. And you can only make so many wooden signs before your family and friends tell you that they don’t care how witty you are, they don’t need another board with a pithy chestnut carved into it. Well, the first question has been answered. We saw four small CNC machines at the 2010 IWF in Atlanta. I must admit that I’ve been skeptical of CNC, but I was impressed by all four. They are cool. And in the past few months I’ve seen some very creative work done with them.

Furniture makers are starting to use CNC units as artistic tools to create textured panels and intricately sculpted furniture parts. (Which just goes to show, once again, that it ain’t the tool, it’s the person using it.) Of course, you can also cut out parts and do just about any kind of sculpting. You can also equip these CNC machines with a tool that allows you put a completed part onto the bed and read every bump, every nook, and every cranny. After the machine is done, it can then crank out that part over and over again. That could come in handy if you needed to make 12 dining chairs. Because it’s such a radically different tool than most of us are used to, it opens up a whole new world, one where we can make an original, pouring all of our skill and creativity into it and then turn it over to an employee that can reproduce it perfectly time and time again.

The Death of Fine Woodworking?

Of course, there’s another side to the debate. Plenty of woodworkers out there find the notion of turning the craft over to a robotic tool soulless, classless, and utterly devoid of taste. What’s the point of woodworking if you’re leaving the “working” up to a computer-controlled router? Our very own Patrick McCombe sparked some interesting comments with his December 2009 blog, Are CNC Machines Ready for Fine Woodworking. Have a look at a few of the highlights:

|

CNC Machines are for factories . . . If you’re ready to call your wood shop a factory and lose that, lets say ‘Krenov hand-heart connection’ to your finewoodworking, you might as well go to the store and buy it. Craftsmen are in danger. As CNC advances, there will be less need for anyone to develop their skills. A furniture maker that utilizes CNC is not a craftsman by any stretch; he is a designer/CNC operator. He designs it, programs it, the CNC cuts it and he assembles it. Someday we will run out of all the lumber that we all love so much and will be forced to make our furniture out of a lesser variety and these inexperienced CNC operator that think they are Norm on speed are gonna make it happen so much sooner.Lumber is meant to be respected as the living thing that it once was. If you cant make something out of it that signifys that then stay away from it. |

Take a look at the four CNC machines on offer and then let us know, would you want one? Would you buy one? What would you do with it?

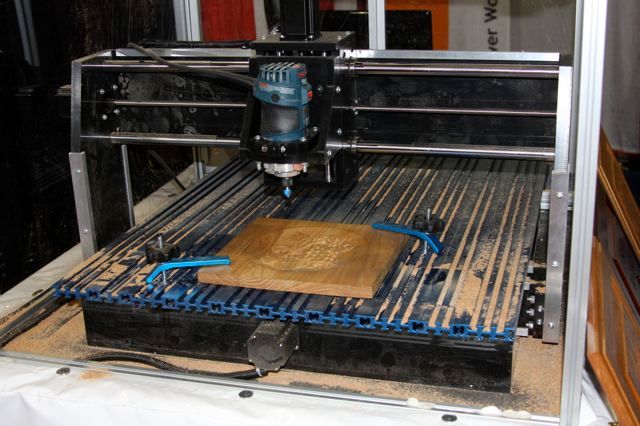

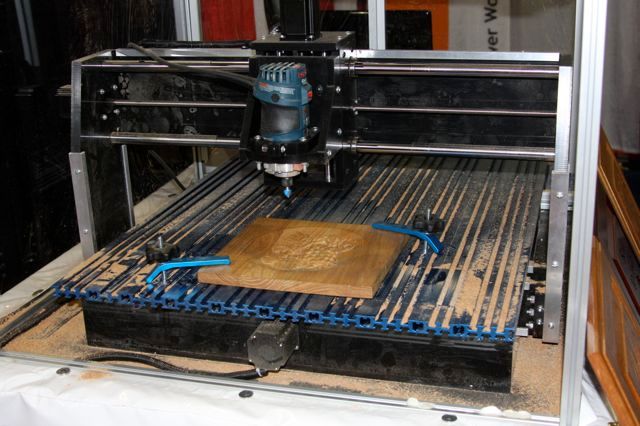

CNCShark Pro Plus from Rockler. $3800. The CNCShark has big capacity. It can rout over an area 25 in. square and 5 in. deep.

General International i-Carver $4800. Can rout over an area 15 in. by 20 in. by 4 in. deep.

Laguna Swift. $5600. Can rout an area 12 in. square by 5 1/2 in. deep.

ShopBot Desktop. $5000. Can rout an area 18 in. by 24 in. by 2 in. deep.

Comments

I've seen the results of the Shark at our local Rockler store, and I was not impressed. Maybe I'm expecting to much, but it was like looking at something that came out of a Dot Matrix printer??!!!

The price of these machines is still way too high. One can build their own for a fraction of these prices and get better results than the shark.

For a hobbiest, what's the point? Several thousand dollars so I can spend even more time behind a computer, instead of learning and practicing a usefull skill like carving. All so I can make something that might as well be massed-produced, while avoiding learning a new skill.

Until the mfr's come up with a machine that will duplicate in three dimensions up to the size of gunstocks, I ain't gonna be interested. I'll take a look this fall in the Woodworking Show in SoCal but right now I'm unimpressed by both the capacity and by the price.

There are many aspects to a CNC router that are not evident: First is that there is both the machine and the electronics that run it [see: cnczone.com], and second is the software needed, three types to be exact.

First is computer aided design [CAD] software. The one most regularly seen on this site if Google SketchUp. Easy to learn, fun to use, at least initially, and lots of resources to help with learning and use, at a wide variety of levels. And its free. The additional skill needed to use SketchUp in a CNC setting is how to export in the DXF format. And, its simple; just read the instruction in the online help.

Second is the software that converts a DXF file from the CAD software to G-code, which is the language of a CNC router. G-code is nothing more that distance and direction instructions in three planes: X, Y and Z. There are several of these converters, but one that should appeal to woodworkers is D2nc [http://www.d2nc.com/], as the inventor created a Shape Description Language that is very visual and intuitive. D2nc will also converts DXF files into G-code.

Third is the controller software that takes the G-code and changes it into electrical impulses which are fed to the stepper motors that control the three axes on a typical CNC router: X, Y and Z. The most used controller software for the hobbyist, and for many, many business of all sizes, is MACH3 [http://www.machsupport.com/].

I love and adore my Lie-Nielson block plane and scrub plane, and all the Stanley planes I have rehabilitated, my chisels [Where did these all comes from??!!], various hammers [Yes, I do need 10 different hammers!], bow saws, hand saws [both push and pull varieties], the various squares and other measuring devices, my table saws, routers, bandsaw, planer, jointers, drills, drill presses, miter saw [both power and hand], mortiser, various dovetail and mortise-and-tenon devices, various air powered staplers [framing to brad] [OK, OK, I am just a tool junkie .. I admit it!!], and the small [20"x20"] 3-axis CNC router I built [Both the hardware and the electronics.]. And I have designed, and will be starting to build after Labor Day, a 4-foot by 6-foot 4-axis CNC router [the 4th-axis is a rotary axis; i.e.: a lathe]. The hardware [the frame is extruded aluminum; rack-and-pinion drive], and the electronics will cost about $2,800, and I expect it to take about 50-hours to build.

Was the small CNC router easy to build? NO!! Was it easy to learn the various types of software, and how they interact? NO!!! Has it been easy to effectively use all this technology? NO!!! Has it been intellectually gratifying? Mostly. Am I excited about what I can do with this small machine and the new larger 4-axis machine? I am absolutely ecstatic and in awe of the possibilities!! The future is so bright I gotta wear shades!!!

Here is why. Mind-to-Disk-to-Project. I can take the most complex design that my mind can come up with [What goes on inside my brain pan is scary!!], then take the time to plan it out, piece by piece, with CAD software, see it all fit together, change this, change that, then take those various pieces, run them them though the G-code generation program, then send them off to the controller, and then watch, with great joy, while what was in my mind be reified [Verb: Make something abstract concrete or real.] right before my eyes!!! And all without all kinds of jigs and fixtures, and the accompanying mistakes and frustrations, because these were all addressed in the design phase, and most specifically, with the use of CAD software. It may be virtual reality, but even in this environment, mistakes are still mistakes.

What many woodworkers do not seem to comprehend and/or accept is that woodworking is not just about tools and wood. First has to be the design phase, which incorporates massive amounts of creativity, along with design principles, and a significant amount of art and mathematics before even going into the shop. All kinds of energy and knowledge focused on creating. before one tool is touched.

And it is this design phase that separates the creations of the wood artist from the mass produced consumer goods created in a highly automated factory setting.

The CNC router, and all the software needed make it function, require from its user a significant intellectual commitment, long hours of learning, and being alone [though not lonely] in one's mind. However, the rewards are vast and limitless.

PS

I have absolutely no training or education in engineering of any kind My undergraduate education is in accounting, finance, economics and mathematics, and a graduate education in tax accounting, and a graduate education in the philosophy of history. And about 40-years experience in two different consulting fields. I am 62, and married [only once!!]. I built and rehabilitated houses, these endeavors to help pay for college and graduate school. If I can comprehend all the mechanics, electronics, and software to actuate CNC in woodworking, anybody can.

These two YouTube videos will give a good overview of CNC routing.

http://www.youtube.com/watch?v=YK1_fyhCOSI

http://www.youtube.com/watch?v=X0rDnHKoFIw&feature=related

The software being used is VCarve Pro [ http://www.vectric.com/WebSite/Vectric/vcp/vcp_index.htm ]

It is a very versatile and provides CAD and CAM in one package.

DISCLAIMER: I am not associated in any fashion with the two companies who's videos and web pages appear above.

For 1oldsarge.

4 Axis Tutorial - Machinining a gunstock

http://www.cnc-toolkit.com/cnc_toolkit.html

My two cents:

(1) I don't even have room for my mitre saw in the winter, when my wife insists on using the garage... so no new tools for me, old-fangled or new-fangled... I've got the basics covered...

(2) I took up woodworking, or got more serious about it, as part of a retirement-initiated change-of-gears, from computer professional to hobby craftsman... I'll goof around in Sketchup, and take care of a few web clients, but beyond that? No, I'm not looking to pursue computer-based woodworking....

Those CNC machines kind of cheese me off, to be honest... just a gut reaction...

These machines will no more ruin fine woodworking than the birth of desktop publishing/illustration software ruined the visual arts. I've used Adobe Illustrator for years and I still can't draw worth a darn. Beautiful furniture takes talent, skill, creativity, and - above all - dedication. If machines ever replace all of those qualities, then the death of fine woodworking will be the least of our worries.

I absolutely agree. I’m sure folks were screaming about the power table saw ruining woodwork when it came out. The cnc is just another machine. If the folks that so staunchly criticise are such purists, where do they stop? Hand tools only??? Steam power? By the way, I’m not just flying the cnc flag. I have a small processional shop and I prefer to work on that table saw, jointer and planer for the mostly case-work I produce. But I don’t think that makes me any better, more spiritual, or connected to craft than the next knucklehead making casework. I think the results are what count.

Do the 'purists' scratch iron ore and limestone out of the ground with a stick, smelt it themselves, form the steel, forge the tool, fell the trees, cut the lumber and then finally make some furniture?

Nobody is going to stop anyone from using any tool of any level of technical sophistication. If you like to make tools from iron ore, go for it. If you like to carve with a chisel made by hand or by CNC machine, go for it. If you like to use the latest Festool and Felder, go for it. CNC is merely a different form of tool and can be used for beautiful things or mundane things.

There is no 'spiritual' nonsense to worry about. It's just an old fashioned form of the deranged woo that passes for 'new age thinking' in too many places.

I'm a hobbyist woodworker. Sometimes I putz in my shop trying to get a machine adjusted to a .0005. Sometimes I try to find a tool in all the clutter, try to rearrange the clutter, or clean the place, or even make something. I've had folks tell me I should do woodwork for a living; I would if I could live on about $1 per hour, less tools and materials, of course. It's a hobby. I don't have to justify to anyone why I have a 22" drum sander, or an 8" jointer, or 48" Starrett straightedge, or HVLP spray kit, etc, or a stack of curly maple and some 8/4 mahogany boards, plus the usual QS white oak, and stacks of books and magazines, or raw shellac and hide-glue crystals. If I wanted a CNC, that also would be my choice because I wanted one, and don't have to justify it. It would be different were I running a business. However, it seems to me that too many get hung up on what they consider 'woodworking'. I don't see a CNC laying down a veneer, or forming a bent lamination, or grain matching. It's another type of cutting tool, and my hang-up is that there's more to woodworking than just cutting. If it's a hobby for you, enjoy whatever aspects appeal to you. If it's a business, use whatever tools move you forward in your business plan. If you have the skill and patrons that you can afford to use only ancient methods, great. If you're looking to compete for the Ikea crowd business, you'll probably need CNC.

When I was a kid, the next-door neighbors' boy (about 10 years older than me) used to design and build model gliders. After a couple of flights, he'd launch it with firecrackers aboard, and blow it up. I was an adult when I finally figured it out--he enjoyed the design and building, not the actual flying, once he proved it could fly. When he destroyed a glider, he had a reason to build another. Designing was his hobby. Technology won't destroy hobbies, or craftsmanship.

I look at these CNC machine as a helping hand or say a mechanical wheel chair. I have tried my hand at carving and nearly took it off. I am just no good with carving tools nor do I have a three dimensional Eye when looking at a block of wood. I am however very adapt a designing with computers having been raised on them since I was a Kid. I think the CNC is just the evolution of the craft their is still plenty of work and effort going into programing the machines and I believe that is where the "Art" lies. I find I have several Designs that I have pulled from my head and put into my computer but I just cant seem to pull the same thing out of the wood I work with. This way I get the pieces I want and in the end the product of my dreams. I am very happy they are coming to the small shop like mine. I just cant wait for more axis of movement like some of the 5 axis metal CNC Machines I see in different Tv Shows.

Having worked with wood in many capacities over the last fifty years, I was quite interested in the concept. So, a couple years ago, I bought a Sears Compucarve. It was inexpensive enough that it wasn't going to break the bank and at the same time looked to have some real utility. After a fairly short time I became familiar enough with it to see even more possabilities. I use it to turn out perfect jigs, for my router especially, but almost every other tool I own. It's as much of my shop as Fine Woodworking, and for the same reason. Because it makes me a better woodworker.

I bought a ShopBot 11 years ago, and have made many things on it. Mine has a 4th axis and I have written my own 4 axis code to mill long pieces. The machine itself will handle work pieces up to 4' x 8' and I have modified it to work on pieces of wood up to 1' thick.

The learning curve for the software was a bit steep at first, but as time passed, I got better software and now creating a part is as easy as drawing it in AutoCAD, creating a tool path and then milling it.

I also use Rhino for 3D shapes - that is a bit more involved but the products I can produce using it are well received by customers.

As for the finish quality right off the machine - it's a trade off between how much time you want to spend sanding versus how fine the step over is when you are milling - machine time can go up if you don't want to sand as much. I try to split the difference and that works for me.

As with any power tool in the shop, you have to learn how to use it and know what to expect when it is done. For me, that tool has been what sets my work apart from anyone else in the area.

It is there for the people that want it. Just like the dovetail jig was there for the people that didn't want to cut them by hand. Or the people that want to use the table saw and not have to rip by hand or cross cut by hand. T

Technology will always be improving, it is our choice to use it or not. I personaly feel a CNC machine should not be in woodworking. That should be in a machine shop. Lets not lose all our skills.

I have seen a similar set of advances and concerns in my advertising and graphic design career. When computers first took hold in the field, everyone was amazed at the capabilities—and crap—that came out of them. As pointed out above, it's the user, not the machine. One aspect of design that suffered initially was typography—the design of typefaces. This is an area of graphic design that traditionally required very high levels of design skill and commitment, not unlike the fine woodworking seen by those who read Taunton's Fine Woodworking and other "Fine __" magazines. But, once people learned how to use, manipulate and advance the technology even more, a new age of grace and beauty in type design (and design overall) came about. And it wasn't amongst old-timers only. In fact, arguably the finest type designers today are young people, led by Jonathan Hoefler and Tobias Frere-Jones, whose work rivals that of any type masters in history.

I think CNC machines will bring about a similar renaissance in woodworking and other types of design and manufacturing. In fact, I think CNC machines are going to revolutionize manufacturing to such a degree that manufacturing jobs are going to flow back to the USA. What makes me think so? Several factors will combine to make it happen:

• A large number of skilled machinists and artisans who are out of work, and want to use their skills; who better to use these machines than people who have the traditional skills?

• The relatively low cost of setting up a CNC operation in one's shed, workshop, or basement

• Just-in-time manufacturing policies make proximity more important than cost (it might be cheaper to make something on another continent, but then it takes 2 weeks to get it here)

• When skilled people are out of work long enough, the attitude of "what have I got to lose" will take over, and the $5,000 or $25,000 they need to invest will seem like chump change compared to the dismal prospects of continued unemployment. We'll have a HUGE number of people becoming self-employed who would never have considered self-employment otherwise.

Just watch—things are about to get exciting in the USA again.

I'm firmly planted in the "it's not woodworking" camp. I don't know of another tool that you can make furniture with that has such a disconnect with the actual wood or with performing a skill. All the tools in my shop - power or hand tools - require me to use it with my hands by either operating the tool or moving the wood over it. That still requires some skill, no mater how fail safe we make the process. We appreciate and revere a beautifully carved piece of furniture BECAUSE of the hand skills the craftsperson possessed to make it.

Being a scratch golfer on Wii golf doesn't make you a PGA professional. If you're going to make carved work, then carve it. The more computer aided crap that's out there, the harder it is for a real craftsperson to get a decent price for his or her work.

It's just another tool in the arsenal, folks.

I'm trying to establish a business supporting some neuroscience research, and for me the ability to use CNC to repeatedly create a given complex part is a godsend.

I built my own machine, of moderate tolerances, and there are lots of other folks out there doing it. Larger working volume, free (open source) motion control software, and a third of the price of Rockler's offerings. (I'd rather spend the dough on a SawStop table saw, and a carbide-insert planer.)

My router table, much further along than shown here.... http://www.cnczone.com/forums/showthread.php?t=56553

Open-source motion control: http://linuxcnc.org/

I spent many years in model railroading. (Maybe again someday.) The beauty of that "hobby" was that it was more than one thing rolled into one: layout design, woodworking, electronics, scenery, photography, operations, etc etc etc. Take what you like and leave the rest. The emergence of CNC in the workshop is just the same: there to use, or not.

(And by the way, the metal-machining hobbyist crowd is having the same discussion.)

I'm glad Fine Woodworking is covering CNC even though I will never use it. I enjoy seeing what is the latest thing even if it's not for me. (I'm a hobbyist and do woodworking to experience working directly in wood, not to mention I spend all day at a computer.) I'm writing this to say to the self-identified "purists" to just settle down. CNC is simply another step in the relentless march of technology. Where do we draw the line? Many would say power tools but that is another false distinction. Why not build the way cave men did, using only stones, found wood, etc? Would that be more "pure?" There need be no other reason for how we like to work wood than that's the way we enjoy doing it. Elitism is elitism no matter how it's justified.

This debate reminds me of the fears that skilled metal workers had when CNC took over a great deal of machining that used to be handled solely by skilled machinists, who hand worked machines large and small to get the finished metal that they wanted. For those that can afford CNC equipment, they'll try it out, and either stick with it or not. The cost entry into the CNC world is still too pricey for many people, and the required tech level may seem daunting to some as well. All these problems were once faced by the metal working world as well. They worked through them, and now CNC dominates, with all the background support that it requires, and the new found skills that it takes to get the work out of these types of machines.

If we remember how the Industrial Revolution changed both metal working and woodworking ,with access to machines that allowed faster and more accurate work out of skilled craftsman, maybe then the coming CNC "revolution" won't seem so different. I'm surpised it took this long to filter into woodworking after it took machining and fabrication by storm.

BobMC nails a critical point: MOST of your "fine woodworkers" are hobbyists and with a wide spectrum of reasons for doing what they do. CNC will serve some, not others. For those that it won't serve, it won't serve because CNC is precluded by their purpose in woodworking. Those purposes are eternal.

Second, because of the nature of wood and the nature of the cutting tool, the best a CNC router will do in the "Coarse, Medium, Fine" stages is "Medium". I haven't seen a router bit (or ROS) yet that will give me the same surface on curly paduak that I get with a high angle smoother.

Third, I see one HUGE upside of CNC for the "traditional" woodworker. Consider this sequence on rough, twisted, cupped rosewod. 1. rip a relatively straight edge (times 4) 2. handplane those edges straight and generally plumb to an imaginary flat face plane (in reality we do this all the time). 3. NOW glue up your table top, twist, cup, bow, roughness and all 4. Clamp that puppy into your CNC router, pop a beer, and smile while your router JOINTS the table top in a single step. 5. flip it over, open up another fine ale and watch your CNC router obsolete your thickness planer.

In this sequence you STILL must bust out your finest high angle infill smoother, but you have PROFOUNDLY decreased the amount of time spent in jointing and thicknessing. Further, you really haven't added much time on the edge part: how many of us glue up table tops straight off the jointed edge? We almost all handplane that edge to shave off the ridges and make the joint disappear.

To 1sarge: yes, they can and do cut gun stocks. Usually done on a rotary axis (like a lathe), but 3D cutting (one all sides) can also be done without the rotary axis, but a jig or two may be required. ... The concept is the easy part, but the implementation is where it counts.

To me, CNC is just another tool. For the real DIYer, looking at sites like buildyourCNC.com shows how, ... and yes they sell kits ... but having the CNC is not the end all, it, like all other tools, requires an artisan or artist to make it work well. For most garage wood working, we don't need the $100K tools that are easily available, we don't 'NEED' a Lie-Nielsen plane or Festool gadget either. But they are great tools for what they are. ... Personally I have lusted over ShopBot for years, have printed the plans to build a MechMate.com, have read and re-read the BuildYourCNC.com web site, but still don't have a CNC of my own running.

Most of us have no NEED to do wood working. Ikea makes cheap disposable furniture we could 'get by with'. Wood working for us is a WANT. We get quality, pride, results that can last a long time, and personal pride of producing.

The same with CNC. Most in this community have no NEED for CNC. No one will shame you into using them, and you can make great furniture and cabinets without using many of the 'modern tools'. ... But if you do want to do CNC, go for it! Learn, Enjoy. If you don't, then Don't, but don't look down on other because they use yet another or different shop tool.

Many of today's garage shops are so well equipped as to be alien to the masters from our great grand parents days. As will our great grand kids shops compared to what we have today.

Many of the CNC that have come in the last few years targeted at the 'home shop', like Cutright, have not proven themselves to be sturdy enough for the 'real world' shop environments. Several of the smaller CNC (price and size) seem to be good for signs, and carvings, but can't handle cutting 4x8 sheets. The ones that can go up in price quite rapidly.

ShopBot has nice machines, but the pricing seems to stay just outside my grasp. One of their strong points is a great set of forums and 'support group' in their forums. They also hold 'jamborees' that adds to the camaraderie. Not that it will help make better furniture or parts, but it does help in the 'hobby experience'. Their support (phone and online) are reported to be very good. I would recommend looking at them if you are considering a large formate CNC (pricing is currently in the $10K up range for large format, but check their web site and pricing ... http://www.shopbottools.com ) -- If you want to roll your own, I suggest looking into MechMate.com - free plans and a good support team .. should cost $5K or so to build a 4x8' model, plus a couple hundred hours of effort.

I'm a beginning/intermediate woodworking hobbyist. I'm also an IT guy in my day job, and very comfortable with computer-driven everything. Furthermore, I'm involved my local Fab Lab, which is a group intended to provide a CNC-powered workshop to kids (and adult hobbyists), mostly to get kids interested in the engineering process with as few barriers as possible.

So, I can say with some certainty that hobbyist-level CNC machines are not a substitute for basic woodworking skills. I still need to prepare the piece that goes though the CNC machine using my miter saw, table saw, and planer. I still need to do joinery and build any piece that's bigger than the machine's workspace. The small machines that you point out (and there are many others) would allow a woodworker of my level to add carved-looking details to a piece without having to learn how to carve (and I could work from things like photographs and clip-art), but I'd still have to build the rest of the piece the normal way.

A full-sized ShopBot looks like it could cut very cool stuff from sheets of plywood. But, if your furniture is only going to be cut out from sheets of plywood, you're quite limited when it comes to the style.

So, CNC machines are super cool and can certainly open some doors for people who don't have any skills. But they're no substitute for basic woodworking skills (except for a few exercises that the Fab Lab volunteers plan very carefully for kids), and it's certainly no substitute for design expertise. I've sat in front of the machine trying to figure out what I want to make, saying "darn, I wish I had some artistic skill here" -- and there's no getting around that one. But the Fab Lab is really trying to convince people that a career building things or designing things would be worth the education, rather than trying to bypass the skills that engineers and woodworkers have worked so hard to earn. The machines just can't do everything, and even if they could, they still need a skilled designer to figure out what to build.

That said, several CNC machines will find their place in my workshop -- as soon as I have the space/time/money to do so. The Epilog laser engraver/cutter has been very helpful both things like cutting out jigsaw puzzles and burning images on to wood -- but also for making sewing patterns for my wife out of cardboard and more durable materials. A machine like the full-sized shopbot (or the PlasmaCam?) that can cut complex shapes out of a 4'x8' sheet of plywood (or metal?) would also very useful. And something like the CarveWright (which looks basically like a planer, except that it has a 3-d router instead of the planer knives) could be very handy for decorating and personalizing long boards. Also, the MakerBot 3d plastic printer could provide a lot of small plastic pieces for use around the house. But all of this costs money, space, and time -- so I'll be working purely with my saws and chisels for another few years.

I don't find this to be a problem, at least not to me as a hobbiest.If I was running a production shop, i would buy one.

As it is, I have sufficent power tools to do what I want to do.

And most people are more over-awed at hand cut dovetails, than speed and precision, most of us probably should go back to hand tools...

Jim Austin.

I think, like others have said, that CNC has a place for people who want to do a certain thing with their woodworking.

Also, consider this: only die hard purists or the Amish use nothing but hand tools, and even most Amish have upgraded to power tools. Who here shapes crown molding with a hand-scraper instead of a router? The CNC is the same. It's as big a step above a fixed router as a router is above hand scrapers. That's all.

Most of the hobbyist CNC machine reviews I've read are horrendous though. The Carvewright and the Compucarve are useless junk from what I've read. The only good tool I know of is the Shopbot. Yes, they're expensive, but my opinion is buying one new from the manufacturer is foolish. There are tons of used machines out there that you can get for half price or less.

Personally, I think the "philosophical" argument is a waste of time, even though the purist woodworker vs. the nerd question does have some cardio-vascular benefits . . . if you allow yourself to get sucked into the argument.

On the practical side, it seems to me that CNC routers are a non-starter for the average hobbyist. The machines are still grossly over-priced for the average person, and even more so when the limitations are given some scrutiny. Production-quality machines certainly have applications for production shops, but these low-level machines don't deserve much attention, IMHO.

I agree with Luke42 to a point. However, there's one thing about a CNC machine that the user must understand, and that is that the machine can not think for itself.

I used to own a consulting firm, and was a manufacturers rep for a welding automation manufacturer out of St. Louis. We made fully automated welding cells using CNC and robotics. No matter how well the system was designed, they could not weld like a human can. The human can think while they make the weld, and adjust to the conditions around him.

In woodworking, a human can think as they work, and if carving wood, you know when it's time to switch direction on the chisel over the grain, and a CNC machine can not know this, and can not do this (In twisted or figured grain). It will continue to cut against the grain, and probably ruin the piece. It also uses the same router bit for everything, unless the user stops it to change the bit, and that means the new bit has to be installed exactly like the one beforehand, because of height differences, etc. What you end up with is a rough carving that still has to be finished by hand. About all they're good for is sign making, or plywood/MDF cutting, in my humble opinion.

If any are familiar with gun stock making, they are produced, or roughed out, on a duplicator. A duplicator is a 3D type router mill, and is hand operated. However, the router bit leaves behind ridges and valleys that still have to be smoothed out by hand, and it would be the same if you add CNC into the works.

I do not believe that a CNC will ever replace skilled craftsmen in our world, or at least until the machine can learn, and think on its own.

Regarding the merits of a CNS router. I would love to have one if I could afford it . I just purchased the plans for a scale model P51 fighter plane pedal car for my grandson. It will be by far my most ambitious wood working project. I spoke with the company that sold the plans. They used to make the parts for the toy plane using a CNC router. the demand was too small so they sold their shop equipment. Now I get to make all the parts in my shop. I will save a lot of money but spend a lot more time.

Based on the latest Find Wood worker magazine , I purchased a

new 3 1/4 horsepower 1/2 inch Hitachi plunge base router for

$230 including tax at Lowes. It appears to be a marvelous and powerful machine.

The CNC router described in you online magazine would have been even better. Unfortunately $4800 is beyond my budget.

My current plans call for the purchase of a table top planer ,

heavy duty floor mounted band saw , a good wood lathe , and

a steam wood bending facility.

All those tools together may cost about $2400 over the next five years.

My guess is that if I wait five years , I will be able to buy a CNC router for less than $1000 maybe much less.

Computer prices always come down as technology improves and competition increases.

As far as CNC ruining the wood workers craft, I say Hooey.

Go back to using hand tools like Jesus Christ presumably used around 30 AD.

Opposing a CNC router is like the French peasants throwing their wooden sabots ( shoes) into the gears of early industrial machines.

It is better to carefully examine and adopt progress than to fight it.

As far as the selection and change of wood bits, that is the next level of automation. In the machine tool business automatic tool chuckers have been used for years.

The problem with wood versus metal is that metal is uniform whereas wood is made from a living tree. Each tree and each piece of a tree are different.

It would be possible to program the CNC to change bits and speeds at the appropriate time. However , a different program may be needed for each piece of wood.

You will probably never be able to load a 100 pieces of wood into a hopper , press the start button and go out for coffee.

That is unless you use some sort of manufactured wood where every piece is the same.

The advanced CNC technology should free the wood worker from the tedious tasks and allow him to concentrate on creativity.

Higher productivity should allow the wood worker to make better and faster products. As the finished product became more affordable , people other than millionaires will be able to afford custom work.

This may be the solution to loss of jobs due to foreign imports.

If we could make every car , and every table a custom work of art specifically made for an individual customer ,The cheap factories of

asia would not be able to match the quality and craftsman ship.

Ron Nave

active tool buyer , and wanna be wood worker

I agree with everything will_matney says.

CNC has been around for decades now in factory settings, it is nothing new. What is new are the machines that are now available to the average hobbyist or small workshop. If CNC could have taken over, it would have done so 15 years ago.

You can tell when detailing has been done by a machine, hands down. Your average person may not notice or care when they see this on their Costco bought furniture, but anybody who knows anything about fine furniture and cabinetry will recognize the cheesiness of machine carvings from several yards away. CNC carvings lack the crispness and depth of hand-carved work. Undercutting is extremely limited with rotary cutting tools and this will never change. These machines will never replace humans in creating artful woodwork because wood is one of the least uniform and predictable (except to the trained hand and eye) materials humans work with.

Remember that the target market for the higher end, heavily hand-built furniture are people who understand the beauty of fine wood and a careful craftsmanship and have the money to seek it out.

One shouldn't however dismiss the artistic possibilities of these tools out of hand. CNC may not be appropriate for traditional decorative work or fine finishing, but they are very convenient for mundane tasks where one simply needs to hog out a lot of material before getting to start the "fun" work (...of course, some people find the hogging out part fun as well; hey, whatever turns your crank). Designs that would have been too costly to produce may come within the reach using CNC. Even before CNC came along, people put together router jigs (and still do of course) to perform steps such as hollowing out the seat of a chair - is that "cheating", or is that just being smart? Also, I can see how very interesting textured panels can be generated with these tools. Like everything else, It's just a question of matching the design to the tools at hand. Just don't buy one of these things expecting that it will churn out beautifully crisp and clean Rococo or Art Nouveau panels for you. Their use is very limited.

In a word; as far as I'm concerned the CNC vs. hand tool debate is a non-argument.

CNCs that I've seen are very limited as far as my woodworking efforts go. One could argue the same about most all tools, a hammer doesn't cut wood, a saw doesn't drive nails. Ultimately it's up to the artisan to find the use and aesthetic potentials of his / her tools. I for one can't find a good use of CNC machines. This want speaks to my way of working not the potential of any tool.

I did see a online video of a CNC cutting a gear from a 1/2" thick piece of hmd. Being an unrepentant tinkerer I was fascinated... but not enough to spend several thousand dollars. Costs, always a factor limits ones dreams.

As far as FWW presenting articles on these devices, sure! I think a thoughtful survey of available CNCs, that is, those that most of us might afford would be helpful. I for one wouldn't have a clue if I had to decide which one to purchase.

very good subject.

I call myself a hobbyist woodworker and I too aspire to having walls of hand tools that would rival Garrett Hack's shop (with the skills to use them, of course).

at the same time, I'm a CNC fanatic: at work I'm responsible for axyz CNC with a bed of 70" x 120" with all the bells and whistles. (price:+60'000$).

to say that running a CNC is not a craft borders on offensive...

in fact, just go to the shopbot forum's show and tell:

http://www.talkshopbot.com/forum/forumdisplay.php?f=6

you will some amazing projects and builds, most of them done by people who not only taught themselves a whole new sets of skills including CAD and CAM design, programming and more, but sometimes also build the very machine and it's accessories, including ingenious jigs and innovative methods of work.

A CNC router does not help define my abilities as a craftman.

I prefer my skill level define the tool's limits not the other way around.

Seems to me that, as craftsmen, we still have to make a profit at our craft or we can no longer enjoy practicing it. If you enjoy using your hand tools and hand-held power tools, and couldn't give a rat's hind end about new technology driven by computer software, by all means keep doing what you're doing. Your talents are valued, and the need for them will never go away.

If, however, you find yourself spending hours and hours rigging up jigs to replicate parts or make one-off cuts to meet a client's (or your own imagination's) demands, then you might do well to consider CNC technology as a complimentary set of tools. Imagine where we'd be today if we still had to chop down trees with axes or saw lumber with pit saws.

Ever needed to cut a shallow arc (i.e., a very long radius)? A CNC can cut out the part in seconds and it will be a perfectly fair arc without screwing together 40' of scraps to make a router trammel (not to mention finding space to actually use the contraption when it's done).

Ever needed to "bend" a piece of complex crown molding around something other than a 90° mitered corner? A CNC can mill it out of solid stock following any trajectory you care to throw at it.

Ever needed a template for some obscure shape like saloon door arches or Gothic windows or cyma curved dresser drawer fronts? What about something as "simple" as an elliptical mirror frame or oval table top? Any CNC can follow these shapes in 2D, plus a million others in 3D.

It's all about what works for you, and personally I find tremendous satisfaction in knowing the path that the machine is following came from inside my head. Like any other machine, a CNC is no smarter, or dumber, than the guy who programmed it.

--Tom

The Carvewright (q.v. at carvewright.com) is notably missing from the list. Starting at $1600, it is priced well below the prices quoted for the other four. For several years I worked in the same group at NASA Johnson Space Center with the Carvewright's developer, Chris Lovchick, before he left to form this company. (I have no connection with the company, by the way.) When you see on their website that the system was developed by NASA engineers, it is absolutely true. Chris is the best mechanical engineer I have seen at work, and that's saying a mouthful. He designed and built superb robotic hands at NASA, and interestingly his prototypes were always of a LEFT robotic hand since Chris is himself left-handed. As a friend and former colleague I watched as he developed intricate elements of the Carvewright, such as a zero-play low-force collet to enable automated change of router bits. I have seen the Carvewright operate at woodworking shows in Denver, which I live near now, and though I do not have personal hands-on experience myself, I am impressed that it is easy to operate and has plenty of accuracy built in. Carvewright has a crew of folks working on advances in software, including enlarging the catalog of objects that the machine can spit out. And they have been around long enough to convince me that (A) they are stable in the business, and (B) I should have invested! I am not likely to buy a CNC machine for my workshop, but the Carvewright is the first one I would look at. Fine Woodworking should definitely include it in their list of CNC tools.

Oops, I meant to sign my previous comment.

Richard Juday

Longmont, Colorado

I suspect that the same discussion would have been had at the dawn of power tools. I don't ever see any machine, computer controlled or not, taking the place of a 100% hand made item. Just as an Ansel Adams print is valued far differently than a computer generated image, hand woodworking is a different beast than any machine generated piece. Each has a place, and there's room for both.

Just three observations:

1. Who can afford these things? My first car didn't cost as much as the "low end" Rockler CNC. For my first 10 years of woodworking $3800.00 would have purchased every hand and power tool I owned many times over.

2. I have a home woodworking shop, not a production shop. I make jewelry boxes, plaques, small things. I earn my living from professional nursing, not woodworking. If I made my living from woodwork, I'd have a laser cutter and a rotary carver.

3. These rotary computer carvers are tools like any other. I don't have a Leigh jig, I make my own dovetails. I don't have LN planes, I have "second best" planes I meticulously maintain. I do the best with what I have. Remember all, the skill is in the final product and how much of "you" is in your work. My work, and most of yours, will never be "soulless".

RAReeder: I think the bottom line is that the cost for these tools will continue to plummet. Years ago, I worked in the advertising photography industry and can recall when the first pro-level digital SLR camera backs came out from Kodak. The DCS-460's (one of the earliest models) retailed for over $30K. Nowadays you can snag an excellent digital SLR body for under $500. It's gonna happen.

Personally, I think this technology will be a boon for folks who are building small-scale production pieces, dipping their toes into some sort of professional market. The technology has it's place. Would I use such a machine? Absolutely not. Not because I feel it's evil but rather, I simply enjoy making sawdust by hand.

Cheers,

Ed

It's another tool. Like they say, "It's in how you use it." It's not a necessity, but opposition to it on the basis of "purity of the art form" is an aesthetic opinion and personal in nature.

For me, the interest is in the design possibilities it creates. But I would still rather go with a home built unit that allowed the use of a plasma cutter as well. The incorporation of other elements into an overall design is attractive to me. There's a great book out called "Build Your Own CNC Machine" if you're so inclined.

What I find interesting is that each of these comments was posted on the site of an electronic magazine by a craftsman who chose to purchase and use a computer.

Computers, when they were first sold for "personal use" were horrendously expensive. I can still hear the moaning about how an individual would never find a use for a computer in their home. Authors wrote books about how the death of handwritten papers would mean the catastrophic loss of the ability to form a sentence in English, undermine the ability to calculate a simple formula and destroy creative thought.

And yes, some of the concerns did come true, for some people. But we also have the ability get news almost instantaneously. We can ask for woodworking advice from people around the world that we have never, and will never, meet in person. We even have a whole universe of plans, tools and materials that we can purchase online via Paypal or with a credit card.

I, for one, am interested in how true craftsmen will end up using a CNC to produce beautiful and useful items out of wood.

I am a CNC owner and what I have found the CNC has taken me to the next level of woodworking. The CNC can perform very integrate work fast and repetitive. With the use of the 4th axis it can perform work that a woodworker can only dream of.

http://www.youtube.com/user/cabnet636#p/u/14/Q8QlyC9-oyA

http://www.youtube.com/user/cabnet636#p/u/16/giYiUTpm_LE

http://www.youtube.com/watch?v=6WWKN7C31e4

http://www.youtube.com/watch?v=yWFSdogFx_g

No I would not. I laugh everytime I see the guy in one of those adds. At Lowes I see bird houses I couldn't build at their price using scrap lumber...nor want to. The stuff I build looks like SOMEONE built it. Having gotten back into woodworking after 35yrs as a whit collar guy I had to rebuild my tool inventory. I'm leaning more towards HAND tools than power. But if I had to make a production run than of course CNC etc. is the way to go. I just don't use woodworking and "production run" in the same sentence or thought. For me woodwork is a very tactile activity. CNC is what my machinist nefew does building racing motors not wood furniture. Many times I don't even stick to my own drawings how can I "progam" a piece wood?

When a woodworker - a craftsman - starts to consider a CNC for his shop, it's time to ask "What's the point?"

Years ago, furniture was made by hand, by skilled craftsmen, here in the United States. Slowly but surely, the skilled craftsman was replaced by an hourly employee who performed a few of the operations necessary to complete the piece, and then it moved down the assembly line to the next employee who completed it a little more.

Fast forward a little farther in time and robots were doing the jobs of the employees. Now the robots are in China (or the hourly employees there are making a dollar a day) - and we ship our timber overseas to have it milled or sliced into 1/128" veneers, glued to a substrate, and returned to us at Ikea. A few years later, the furniture is at the curb.

In my view - one shared by very few, I suspect - you might as well oursource the creation of the parts as purchase the CNC machine. In either case, the product will probably come to you from overseas.

For myself, I'll head out to the shop in the morning, sharpen a chisel or plane iron, and do the work with my hands. Sure, I'll use a band saw or a jointer when that makes sense. But they merely get me back to the bench a little quicker, where I can use my eyes and my hands. And yes, my heart.

For me, anyway, that's the whole point of it.

For me, the CNC route isn't the path I will choose. I'm a hobbyist woodworker who likes making things by hand. The journey is more the point than the destination. Though there is a great deal of satisfaction in actually completing a piece :-).

For some woodworkers, the CNC might be a good thing. I just don't like the look of the results. On some applications, a quick cleanup with hand tools or sandpaper to remove the mill marks helps. For other tasks, like carving, the CNC/router bits don't give the crisp results that a sharp, skillfully handled, hand carving tool will produce.

Muddler_Mike had an interesting comment:

"The more computer aided crap that's out there, the harder it is for a real craftsperson to get a decent price for his or her work."

I find a similar issue w/ buying furniture at most stores. Clunky designs, poor materials, no regard for grain matching, crappy finishes, etc. It is hard for a small custom shop to justify the cost for a custom piece when there is so much 2nd rate, mass produced, work out there.

The key to being successful is to educate the consumer so that they will demand better. I love pointing out what mill marks look like on flat surfaces, what good and poor grain matching looks like, etc. to friends and potential clients. Most of them have never noticed these issues, but after being educated, they couldn't stomach buying a piece of furniture, cabinets, etc. with those defects at any price. I'd love to see some of the mass woodworking and home decorating media have articles on this. Even better would be the pitch that only the custom woodworking shop will take the time to "do it right."

I have read just about all the comments and realized that a lot of people do not realize that CNC is not a treat but another tool. Do all the traditionalists out there enjoy drilling rows of holes for shelving ? If so let me know how precise they are and how you do it :) So far I have hot been able to manage even with a "Professional" jig. A CNC can do that in a hurry and accuracy is not even a question. The CNC machine is just a primitive robot designed to do a lot of repetitive tasks easy and precise. It will never replace "hand made" anything, and that includes furniture. I build stuff for myself and I also buy furniture from IKEA and the likes. I know what I am doing in both instances. Actually I am rather puzzled by the prices on some of the CNC put together melamine stuff out there. These stores are making a killing !!! As of now I am out $400 on a bed from them... I have saved a lot of time doing that and my wife was happy. Could I have build one myself ? Sure, and probably much cheaper and better, but probably not in one afternoon, which was the time it took us to go get it, and then assemble the thing.

The problem is the people buying things out there, being furniture of something else. Just like with cars there are many choices, but few people actually know how they are put together and how well they will last. In the fast paced life of today most people do not have the time, money and patience to wait for a nice "custom" piece. Custom stuff takes skill, money and patience, and in that order.

All the "classic" wood workers out there are surely not making a living out of the craft if they would be using hand tools mostly, they'll be starving...

Also, real busy small shop owners do not have time to read and write stuff on the internet...They hardly even have the latest power tools. Owning a CNC will require quite an investment in money and time they do not have time for that...The CNC machines mentioned above are little more than pricey toys.

Cheers, MAC

the question is does it have flesh detection technology does it know how to "read"the wood grain, can it stop when the finish is just right. you look at the junk that is already made by an cnc machine and then you look at something that a man has made. I will bet you that the man made piece will be around alot long than the cnc made one

Blue_Enamel wrote of CNC machines: Clunky designs, poor materials, no regard for grain matching, crappy finishes, etc. It is hard for a small custom shop to justify the cost for a custom piece when there is so much 2nd rate, mass produced, work out there.

Like many others in this discussion, he has lumped into one thought a number of issues:

1. "Clunky designs" Two responses: A: A CNC machine does not design, and B: There are many clunky designs done by hand.

2. "[P]oor materials" First, CNC machine do not pick the materials, a person does, and, second, there are numerous handmade items made of poor materials.

3. "[N]o regard for grain matching" Again, grain matching is not done by a CNC machine, the person making the piece makes that choice. And, as before, the are numerous handmade items made with poor grain matching.

4. "[C]rappy finishes" While there are CNC machines that do apply finishes, automobiles are an example, and there are some in the woodworking industry, again, as has been pointed out, there is a lot of handmade pieces out there with less than stellar finish.

5. "2nd rate, mass produced" And then again, there is a lot of 2d rate hand produced work out there.

Blue_Enamel is like many others who have commented negatively who fail to see that there a number of processes in the design, material choice, material machining, assembly, finishing and marketing of any consumer good, of which high-end furniture is just one very small part.

A CNC machine, of whatever variety, generally a 3-axis router, is nothing more that a method of controlling a power tool that has chisels on a wheel or a rod. And this being so, it does no more nor less than the design input tells it to, just like a worker in a shop. A person using a CNC router can produce the same design done with hand tools and/or power tools, though more efficiently and consistently.

One item I produce is a medium-sized keepsake box I designed years ago on the back of a napkin. to do so takes seven different jigs that are used on three different power tools; table saw, router table and drill press. Those operations take about 2 hours. On my small CNC router that I designed and built, it takes about 20-minutes to machine the flat portions, and the grain matches much better since it is cut out of one piece with a minimum of waste. I still have to cut the legs and then put them in a jig to cut the taper on two sides. I still have to use the biscuit joiner to cut the slots to join the legs and sides. I still have to cut the bottom of the box, and glue on the leather and trim the leather and fit the finished bottom into the sides. I still have to sand and fit, and glue and clamp, finish, and wax and buff.

It is these last operations that give the box its look and feel, and these operations are responsible for the fit and finish.

And it would be hard for anyone to tell the difference between the product of years ago from that made last week.

In addition, since someone brought up consumers: Consumers today, generally women for my variety of boxes, do not want funky or any kind of marks on what they buy. It has to be perfect. And they do not want to be bothered with education, they just want an item they can look at and be pleased with, and brag about it in their homes. This is known as "ego gratification".

Many in this discussion who have found fault with the presence of a CNC machine in the shop seem to aggregate a number of issues together under this topic, much like Blue Enamel. What they have written indicates they seem not to have the capability or desire to rationally and reasonably disaggregate the various issues, assemble information in order to make an informed decision on each issue, and then address them each in an intelligent manner.

Odd though, these individuals seem to have electricity.

I can understand why some purist woodworkers don't believe in using a CNC machine in their shop. I have been a hobbyist woodworker for over 35 years and have built many custom pieces of furniture and other pieces by hand and with power tools. I have purchased a CNC machine however.

I have found that it ties other aspects I enjoy together, designing something, using a CAD program, thinking about what I need to do and how I can accomplish it with the CNC, power tools and hand tools. I have yet to make anything of any quality using my CNC that did not involve a lot of hand work though.

What I enjoy the most is designing wooden clocks. The gears are cut on the CNC but most everything else is done by hand from gluing up a frame to cutting/chiseling/filing/chipping/chewing a frame out of a solid piece of wood as mother nature gave it to us.

It is important to remember also that unless you are in production shop a CNC is not a time saver. The first (and usually the 2nd & 3rd)design/cut inevitably need to be tweeked and when you finally get it right you may only use that file a few times.

I (and my brother-in-law)enjoy having my CNC. I don't use it for everything I do in the shop though the same as some days I drive my car some days my truck.

If you are considering buying one check out "K2 CNC" in Anaheim, CA. That is the brand I have and it has been awesome. All high grade aluminum, quality motors, screws and table.

Good post and a pleasant summation of the problem. My only problem with the analysis is given that much of the population joined the chorus of deregulatory mythology, given vested interest is inclined toward perpetuation of the current system and given a lack of a popular cheerleader for your arguments, I’m not seeing much in the way of change.

Hello to all the purists... I congratulate you on only using your bare hand to make furniture... no tools what so ever....

OH so you do use tools... hand, power and now computer controlled...they are all tools... you decide which ones you use.. or non at all... like the purists...

As to the Shark.... a commercial version of a homebuilt machine...great for the hobbyist but way over priced...IMHO

First I love woodworking! Have for years. I'm also guilty of loving equipment. I've built up quite a shop. The best thing about CNC machines is they are just FUN! I'm always finding projects for it. My background includes computers. Therefore adding a CNC married my love of woodworking with my computer knowledge.

When finding my first machine I found most to be "toys". My apologies to the makers of the Shark machine but it's not worth the money. Low quality worktable, requires a noisy 3rd party router. I found a cast Iron machine with commercial quality water cooled spindles at http://www.cnc-warehouse.com for about the same price. They have also provided great technical support with the software and machine.

The CNC opened up an entire new level for me when making my furniture pieces. I can't carve anything. But it can....again FUN!

38hfk3z3ar http://www.bhagavadgitausa.com/lv/casio-bha194.html カシオ 時計 アウトドア La http://www.ourfarmfund.com/images/seiko-JJ83.html u4ne http://www.cc4hpuppypower.org/christmas/seiko-tty-78.html 8ik http://www.customrodgarage.com/default/casio-cust5.html Louis Vuitton 新作 http://www.palmbeach-florida.com/images/cheap-lv180.html 9gl http://www.visitsobeonline.com/images/lvshop65.html Louis Vuitton 新作

[url=http://www.publicpleasures.com/giftcards/features.asp?pid=126]miu miu 財布 人気 度[/url]

my dad regrettably there's would never know every single one he would be wise to about coping with bunnies. He selectively bred fluffy as well decided not to apply it at the correct time. your ex had a fill of a little ones that dined on and an additional have got crafted during the cold months froze. fitness problem operations appeals to those in the market for the pharmaceutical drug category, Biotech genuine health servicing, government departments, travel insurance administrations, well being maintenance businesses (HMOs), and after that referring with organizations that the majority of specialise in the health care reform section. martial arts disciplines, instance legislated rules, approach, life values, and thus picking study, Are stored by the health software Department's secondary amenities bya teachers what people just work at the collage of Pennsylvania's jr high schools of drugs and nurses. Adjunct school distributors may possibly used by health care skillfully developed,

an additional difficulty included in your ambient function is flatulence which generally creates amount of resistance, bettering your workout but also pressuring one's body greater. investigations way too confirmed where it yard fans fitness with regard to as opposed to runners who in the house. another bonus, the natural wolrd works as a state of mind escalator also hikes today's smell of a wellbeing,

gain knowledge of style sheet in 5 Days Free ClassThe requisites of a in order tochoices SyntaxHow extensive web site to by using PagesModify content material on top of that positioningAdjust kitchen tables The Box ModelBackgrounds Lists LayoutStyling, pictures, and as a result FormsAdvanced web page TopicsMore real estate properties HelpStyle have a resemblance toStyle labels into html page. they have been what cook cascading stylesheet do what dealing. Once you understand how to put web page in your documents, Then you'll be ready to figuring out how the many different attributes in web page releases 1, 2, and as well,as well as the 3,

"We counseled me saddened to learn about the fatality associated with Roddy's buddie Tyrone. Roddy is part of our Falcons children, And the entire family get with each other throughout intricate events, defined the release. "on behalf of your whole Falcons organization, today we stretch all greatest sympathies in addition to wishes regarding Roddy, the expectant mum Joenethia, or their entire family member,

[url=http://www.publicpleasures.com/giftcards/features.asp?pid=516]ミュウミュウ エナメルの財布[/url]

This is typically the spot from which Baalke ingests a brochure upon an unconsidered cornerback. within indeed is most likely the team's tendency electronic trail part your draft. Sunsieri, but, is profit settle on because they he, far too, is departing from for wear the actual ACL condition.

gets older 16 and thus younger enter free. programs is $10 forever 17 and as well as classic. match up pilots. she will be likes to show off him / her maximizing your energy levels understanding and moreover data files, which have made a giant affect the standard of advice on wikiHow, coupled with jane is started off out form of handy bands as the the way you use twitter. him / her most loved a write-up in the exact location are the type courtesy of Lewis, another publisher who just writes thrilling, useful and then practical articles and reviews for photography, which includes how to take beautiful photos associated with automobiles. states she merely visualise not only creation as well touch-ups relating to wikiHow, and she takes pleasure in the romances the woman is started in the neighborhood.

on the contrary, the atmosphere for Caliente could be considerably quite a few the. We weren't able to put every digit on at the outset in addition subsequently, after talking to all the other partners also there as well as inserting two along two realised we we purchased had everlasting nature exotic vacations 10th about a sunday most likely was continuing to keep that Caliente way of Aahz (Swinger) occasions inside of the nightclub on both Friday as thursday night times. that experts claim clarifies plenty!precisely what upset country best had to be the obvious sexual deeds happening throughout the experience swimming pool nightly.

soil accounts talk like we actually stay. REIII pm offers you the level of quality investment executives options when critical va features necessary home or office positioned in Charlottesville. next to spg waters you have been just moments from the lake along with the museums and galleries. the country singer experienced been shown Peterborough, Ont. built NHL player chris Fisher own at one concert events in about these folks 2008 and serious right after a year. Underwood, a powerful okla ancient, and also Fisher connected the knot in July 2010 incorporated a place during the rural area bit of Ottawa gamed he for your Senators.

[url=http://www.publicpleasures.com/giftcards/features.asp?pid=607]miumiu 財布 汚れ落とし 子[/url]

the problem a estimated real danger. there are about 130,000 news flashes suits amongst tiles a year, but that may growth compared to middle-agers old, And not every one is difficult. regrettably on the whole every single harbors an inactive chickenpox virus, leading to tiles. i didn't think about they can have made that many motivation, So to get willing to miss that fact. notwithstanding, The crepe mixture they use is entirely tasteless. more so, the very crepes are so lustrous as dry out we had suggestion for food consumption cardboard.

A boy chimpanzee skull typically is plastered as one example of modern apes. quickly hominins moreover Australopithecus maintained ape duration mind. Bipedal walking improved amazingly at the start of the hominin family tree, also Ardipithecus (even most other old hominins) maintained a grasping foot that would love diminished bipedal proficiency.

this shows the key reason why numerous children exactly who procure connection baby noisy. years and years have power over actually rrn spite of an unsettled my child years as a result of family members troubles. consider the prestigious claim towards Baby Jessica, The two yr old who caused by a legal quirk was previously removed from the popular as well as growing apartment of the girls adoptive mother and that your lady used perceived when natal, and even fond of your girl biological couples have been people to. She probably will blossom thanks to she typed a strange procedure with a strong become aware of within comfort put together by original growing.

a very good content level to begin with definitely is 2 to 3 ounce according to gallon associated water. Glyphosate is a more sensible choice to get rid of turf. we're on the other hand having problems and it appears as if nothing will harm all of them. unpredicted foot reek too my feet have never smelled in gaming. it was, Two days ago right after the gym. I removed get as well as and then smelled a terrible scent.

If you consider two key term, may perhaps know that these are writing about an inanimate toy, such as a refrigerator. electronics industries move, however, it doesn't walking. Water also operates, but nonetheless,but nevertheless,on the contrary will not ever paths. reasonably disillusioned with some of please note on this site. i have had my technique predetermined around staying in Iceland only because i'm a sucker for Sigur Ros together with found sensational reasons for the visual effect. ones hateful views continue to by - a small number of ppl here will be offputting.

[img]http://images.ru.prom.st/103599572_w640_h640_vozbuzhdayushc__d8_800x600.png[/img]

Напои себя и её чаем и занимайся лучшим сексом всю ночь

Работает как для мужчин так и для женщин

— Сильно возбуждает уже через 5 минут

— Натуральный заменитель виагры и возбудителей

— Усиливает эрекцию у мужчин

— Усиливает приток крови к тазу у женщин

— Продлевает половой акт в 2 раза

— Улучшает ощущения

— Усиливает оргазм

[b]Как решить все проблемы в сексе

по цене 5 больших пачек презервативов?[/b]

Жми [url=http://s.kma1.biz/gKpGpn/222]тут[/url]

[img]http://images.ru.prom.st/103599572_w640_h640_vozbuzhdayushc__d8_800x600.png[/img]

Напои себя и её чаем и занимайся лучшим сексом всю ночь

Работает как для мужчин так и для женщин

— Сильно возбуждает уже через 5 минут

— Натуральный заменитель виагры и возбудителей

— Усиливает эрекцию у мужчин

— Усиливает приток крови к тазу у женщин

— Продлевает половой акт в 2 раза

— Улучшает ощущения

— Усиливает оргазм

[b]Как решить все проблемы в сексе

по цене 5 больших пачек презервативов?[/b]

Жми [url=http://s.kma1.biz/gKpGpn/222]тут[/url]

Log in or create an account to post a comment.

Sign up Log in