IWF Alert: Ready-to-assemble furniture contest awards student creativity

First place: "Safe Stand" by Hunter Jones, Reed Lowry, Stanislav Karmalyuk and Preston Watson

One of the hightlights of the IWF for me was the ready-to-assemble student furniture contest hosted by Woodlinks USA, an organization dedicated to helping high school and post-high school woodworking train skilled craftsman. The furniture made by the finalist was impressive, especially given that most of the finalist were high school students. So too was the creativity on display. Like many of you, I’m aware that woodworking is a hobby for a mostly older crowd and it was encouraging to see so many young folks interested in furniture making. I’ve listed the winners below, along with a few comments about their furniture.

First place: “Safe Stand” by Hunter Jones, Reed Lowry, Stanislav Karmalyuk and Preston Watson (Dale Jackson Career Center, Dorchester, Texas).

This is a very clever piece of furniture. Sure, it looks like a end table or perhaps a cofee table, but in reality it’s a safe. Yes, a safe. The four sides are held together with pocket screws. The top is two layers. The upper layer looks is simply to the top of the stand. The underlayer, however, conceals four long dovetail keys. These fit into dovetail slots mortised into two of the sides. The students figured out a way to get the keys to be locked in the slots in every position but one. When in that one position the top comes off. Otherwise it’s locked in place. The groups spokesman told me that it works as a safe, because the safest safe is one that nobody recognizes as a safe (I was a bit skeptical because a circular saw would make quick work of it, and who doesn’t always have one with them?). And I certainly wouldn’t guess that this piece is a safe. I won’t tell you more because I don’t want to give away the secret. I asked who the intended audience was and the guys told “college kids” and that they could keep their game consoles and other valuables in it during parties in their dorm rooms or aparments. I responded by saying that they had basically made the ultimate stash box (if you don’t know what that is, you haven’t watched enough Cheech & Chong). They laughed and agreed. Of course, it could be used to store more legitimate valuables, too.

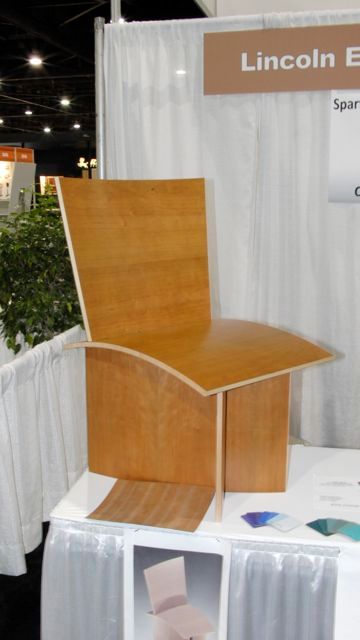

Second Place: Cross Curve Chair by Nick Grabowski, Taylor Kingsley, Brad Pickerall, and Drew Zobel (Lincoln East High School, Lincoln, Nebraska).

I really like this chair. Not only does it have a cool design and construction process, it’s also comfortable. It made of four curved panels: two “legs”, a seat, and a back. The legs criss-cross over one another and attach to the seat with some crazy strong hook-and-loop strips. The back has tenons on its bottom end that fit into mortises cut into the back of the seat. The core of the panels is made from resawn and sanded poplar plies glued up in a vacuum press. All of the panels are made using the same form so that they nest and fit into a very think box for shipping. The students can laminate wood veneer or plastic laminate over the core. They also told me that they can make an upholstered version.

Third Place: Three tiered end table by Jason Rundhang (Madison Area Technical College, Madison, Wisconsin).

This table could easily be made with traditional techniques, but Jason found a smart way to make it easy to ship and assemble. The top is held to the four legs with figure-8 hardware, and the shelves rest in dadoes cut into the legs and are held fast by bolts. It’s a sturdy table. What I like best was the top. He made it by laminating strips of Baltic-Birch plywood on edge so that it had a modern, cool look.

Fourth Place: Demilune table by Patrick Prophet and Kenton Beard (Halifax County High School, South Boston, Virginia).

I was very excited by this table, because it has, in my opinion, the most inventive joinery. Patrick and Kenton used rare earth magnest to hold all the parts together, and it was a sturdy table. The three legs are indexed to the apron by very small tenons (made from dowels, I think) and then held in place by a magnet. The top is held to the apron in the same way. That’s incredibly inventive and could have endless appication. Just think, you could make a mortise and tenon joint that was knockdown by putting magnets on the tenon cheeks and then down in the mortise. That would be a very strong joint. Here are some other cool features: the legs are steam bent, the apron was CNC’ed from a brick layup, and the top had some great veneering. A very impressive piece.

Fifth Place: Quilt rack by Jorden Berry and Tyler Butterly (Harper Creek High School, Battle Creek, Michigan)

Sometimes simplicity is the best choice, as this quilt rack shows. The ends are glued together and the stretchers have a dowel at each end that registers in a mortise. A screw is then driven in from the outside and wham-o you have a solid quilt rack. And you know what, both racks they brought to show sold. That’s saying something.

Read about other great tool finds at IWF 2010

Comments

What you don't mention is how the fourth place winner's project fell apart while the judges were looking at it. Shoddy job in my opinion. There were other projects more solid and much more worthy of recognition than this one.

Log in or create an account to post a comment.

Sign up Log in