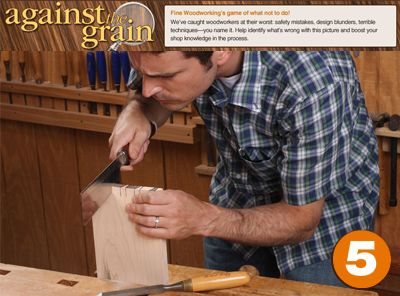

Play Against the Grain 2, Dozuki Disaster.

Against the Grain: The Wrong Way to Rip

Normally, when I post new editions of our Against the Grain game, I infuse a wee bit of humor into the text. ATG 2 was dubbed “Dozuki Disaster” and featured a photo of yours-truly with some self deprecating text beneath it. This time however, I’m taking off my comedic attire and taking a more serious tone.

|

More Tips for Safer Rips |

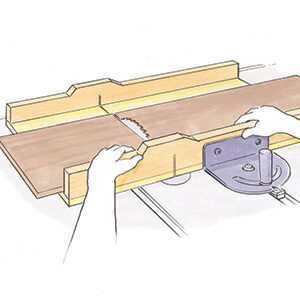

Kickback is one of those dangers that’s ever-present in any shop with a tablesaw. That said, no matter how safe a person generally is when working with power tools, everyone slips up once-in-a-while. Maybe it’s the end of the day and you just don’t feel like hooking up the fancy auxiliary fence. Perhaps you’re on your last cut and you figure you can wing it without the push stick – just this once. Whatever the reason, we all let our guard down (no pun intended) from time-to-time, even if we don’t necessarily get burned as a result.

Case in point, my fellow Lumberjocker, Rob. Due to a faulty throat plate in his tablesaw, he suffered a nice gash to his head (luckily not to his eye) when a small piece of stock came winging at him after it caught the lip of the plate, twisted just enough, and well, you know how it works–or do you? After you’ve played this edition of Against the Grain and found the five woodworking no-no’s, be sure to read, and heed, Rob’s story. It’s no laughing matter.

Play Past Games

Comments

Rob's accident could happen to anyone, experienced or not.

One more reason I dislike using a table saw and always use an alternative when I can - bandsaw, or more often, my Festool TS-55 track saw and MFT 1080. Safe, great crosscuts, great rips, easy angle cuts.

And a complete Festool TS-55, Track(s), MFT/3, parallel guide(s), etc. is far less $$ than a Sawstop. (Its Festool $$$$$$ pricing remember..:>.

Plus you can rip an 8' board in say a 12' space. Not 16' plus..

Rob's a lucky guy!!

I wear a forester's head guard with an integrated ear protectors, though replaced the mesh face guard with a plastic face guard.

Keeps flying dust, as well as larger pieces out of my face and eyes. My glasses are shatter-proof.

I custom made a shop apron, it has a baseball catcher's protective vest under it. I am 6-3, so kick-back REALLY hurts! Only happened once; that was enough. I think the ribbing I took was more painful though.

As much as the whack in the head from the board hurt Rob, I bet the one from his wife hurt even worse!!

It would be nice to replace all of our existing table saws with Stopsaws but that is not going to happen. Maybe the Stopsaw folks could come up with a way to retrofit their equipment to our saws. I would spend the money for that.

I follow almost all of these rules and then some. If I break a rule it's by necesity, but I remember what my old music professor told me when I was in college. He said that I needed to know the rules backward and forward before I break one, and then only by design, not serendipity.

I always use a push stick, I make my own and most of them are chewed up. Better them than my hand. I always use the splitter and so on. I may not always have support for my work if space does not allow. I also always use eye and hearing protection. I've been blind in one eye before (not from woodworking) and it's no fun. I also have a well developed case of tinnitus (ringing in the ear) not from woodworking and would prefer it not get worse.

Yes a riving knife has been standard on European saws for a long time but it is just HALF the equation. The other half of the safety equation is it's old mate, an overhead guard adjusted such that is leaves minimal space between it and the piece being cut. Not only does it significantly reduce the likelihood of contact with the blade, it very much improves the dust collection capabilities. A clear guard still affords view of the blade, and if fitted with its own dust collection facilities will ensure almost no dust being released during the cut.

Yes there are times when a blade guard cannot be fitted, arguably times when this is also not the right tool for the job and a bandsaw would be a MUCH safer option. However in this example there is absolutely no good reason one couldn't be used, yet it was not even an option in the so called "safety" game!

For some bizarre reason, table saw blade guards are rarely seen in North America, and as a foreigner used to using one every time I use the saw I simply find that attitude ... well bizarre! Much better to look for the good old "instant pill" solution of something like a SawStop (a device incidentally I believe is an excellent addition).

As mentioned, I use a TS guard EVERY time I use a saw, and cringe when I see a saw without one. I have absolutely no idea where this philosophy of not using one has come from, but I suggest it is absolutely unique to North America. I think it's about time the US caught up with the rest of the world and Fine Woodworking should play its part in leading by example.

A rant I know, but I'm simply horrified at the number of TS injury statistics that occur every year in the USA. Look them up. If you dare!

Wow, this story struck a nerve with me... or, like this story, my nerves were recently struck as I had my first kickback a few days ago. I could not believe the force the workpiece had... it hit me flush on my side and actually left an impression of the workpiece, including the grain of the board. Definitely caught my attention... I will be stepping up my safety.

I don't know if it's ok to put links in here (apologize if we're not supposed to) but here's a link to my incident with pictures. If you haven't seen a box joint imprinted on flesh before it may be worth a look, lol.

http://www.woodzealot.com/2010/08/28/how-to-use-kickback-for-laying-out-joints/

Charles

I went from +200 down to -240 points trying to find the right place to click to indicate the lack of a guard and/or riving knife. Finally saw it lying on the table, but it would really be nice if you provided an "I give up" button as a last resort.

It cost me a piece of thumb before I finally stopped doing stupid things with my beat-up old Craftsman table saw. Its replacement, a Bosch portable, makes it much easier to be safe. The Sawstop or a tracksaw are wonderful options, but neither my budget, nor my space, nor my needs can justify them.

You can never have too many reminders to follow standard safty practices. I have several Safety hold downs and push sticks. We must always remember to use them. An interesting thing I once read was that a good percentage of car accidents occur within a mile of peoples homes. That is because people get careless when in their comfort zone.

Great game toaday as I've been guilty in the past of few safety precautions, but no more

Thanks

How about those long sleeves?

It only took me one good kickback accident (20% nerve loss in left middle) to "get my mind right" several years ago. As we all know, the spinning blade is something to avoid, but the velocity at which it can throw stock is perhaps the more likely hazard. I now will not turn on the saw without wearing a face shield, having a properly aligned riving knife (unless absolutely necessary to remove it), and simply will not rip without holding GRR Ripper push devices properly set to control waste and keeper. Also, spray the always sharp blade with a lubricant before cutting. Rip fence ever so slightly angled away from the blade. Knock on you know what, I at least have felt in control ever since becoming a believer. (Question: where do you suspect those tiny bits of carbide are headed when they chip off the teeth of that spinning blade ?) Face shield is a no brainer.

hhmacdonald:

I have a feeling that much sooner-rather than later-some sort of sawstop-like technology will be standard industry practice. Heck, might even be federally mandated for all I know.

Also, lots of folks here are talking about splitters and riving knives - perhaps one of the best--and simplest add-ons to a tablesaw.

Best,

Ed

Gotta wonder about the "Stand Clear" correction on this particular game. Yes it's good to stand clear of the likely path of kickback, but the operator was repositioned such that his right arm had to reach OVER the blade in order to guide the work.

Would a better solution have been to push left handed, so the operator's entire body is clear? Or to reposition the fence so that the operator could work right handed and stand clear?

I know you are talking about kickback, but long sleeves are a no-no.

I was also told to raise the sawblade to 1" above the wood to get a better cutting angle on the downstroke. What do you think of that?

I apreciate all the comments, I grew up on a radial aim saw and have been using a table saw just in the past couple years.

I am an ER physician, and I thought I'd share this story about kick back. I saw a guy who was working at the job site on a contractor saw, and unfortunately suffered a kickback injury. The small piece of wood hit him on the right side of the neck. It only left him with a small nick in the skin. However, when the piece hit him, he dropped like a stone unconscious for a few seconds. This prompted us to investigate his carotid artery which lay just below skin at the site of his injury. Sure enough, the force of the kickback has torn the inner layer of blood vessel. He had to be admitted to hospital and put on blood thinners and watched carefully in case he developed a stroke.

it certainly humbled me as to the dangers of kickback.

1/4 ply is another dangerous rip - I had two kickbacks from this material, one requiring sutures to my hand. Use your guards and splitter.

Next time you get something protected by a styrofoam sheet and feed it through the saw to see the dynamics without the pain.

What about the ring? I believe a critical mistake the game missed is the ring on the finger. Many fingers have been detached due to accidental catches on running equipment. Standard OSHA polices require that all jewelry (rings, necklaces, watches, braclets etc.)must be removed while operating any piece of equipment or tool. A ring can easily catch a sliver / splinter and unexpectantly pull the board back...ouch!

And dude where are the carharts?

PapaDisco: First of all - nice screen name. Regarding your comment: the problem I've found with positioning to the right of the fence lay in the direction you'd then be applying your force. The user would be inadvertantly applying force towards the blade - as opposed to towards the fence. That would be another kickback-inducing situation in my humble opinion.

That said, I think your comment about the arm nearly crossing over the blade is a very good one. In fact, it's something that I've often wondered about myself. Many times when ripping a board, you can't help it. That's why I've always grabbed the table with my left hand during those situations, to steady myself perfectly. I find that I have much better control when I grip the tabel just to my left. Of course, I always check that I'm using a sturdy saw that isn't going to be jostled at all by my grip.

All-in-all - great comments, folks. The ring one has been debated at lenght- there are two very well-entrenched schools of thought and both make good points. Ultimately, that's up to you.

Thanks for playing guys - and for sharing your own experiences and points here. Hopefeully, these comments will prevent serious injuries for some green woodworker out there.

Best,

Ed

PetedaPilot makes a good point about the guard needing to be in place. I replaced the nut and bolt holding the poly guard in position on the splitter of a Unisaw with a sailboat type push pin. I found the guys much less likely to remove the whole assembly when they were able to just pull the guard and replace it quickly during close cuts. I too have taken a kickback to the face. Not a bad one, just a stinger. Stand aside, push sticks and the guard in place are my rules. Never push on the outside of a board is another.

I could not find where to click to show that a blade guard is needed. Riving knife of course a necessity and a blade guard cannot be used on all cuts, however this rip cut in the photo in my shop at least would have a blade guard.

I did notice that this cut was being made on a SawStop saw so I guess that for that reason a blade guard is not technically necessary.

Being a dentist I am especially careful in using proper safety equipment and safe technique for my own benefit. I personally would like to see that all woodworking shows etc. use blade guards and safe technique for their demonstrations. Not every woodworker is aware of the potential danger of a table saw.

This game is a big plus in bringing out these potential dangers to the readers. Thanks!

I was wondering why all the saw dust he is standing on is not a hazard of face planting the blade

Good Comments All

Just want to echo Mikey's remark about hunting for the last error.

As a matter of technical design, these "Against the Grain" dialogues should have an option for "I Give Up Already, so show or tell me the rest". I experienced the same need in the Dozuki piece.

Whenever I do use the tablesaw for ripping, (and lately I'm using the bandsaw more often), I will use featherboards both to hold the stock against the fence and also two featherboards on the fence to hold the stock down to the table. Belts and suspenders? Yep I guess it is. But the increased safety is worth it.

RGCopple: That "I give up" button might not be a bad idea. Let me run it by the folks over here. And thanks for the suggestion!

Cheers,

Ed

I was using the "MAG" hold downs for a featherboard and to hold the workpiece flat against the table. All of a sudden, the piece broke the hard plastic on the MAG Switch and threw the piece back at on on the "left" side of the table. When I first looked at my had I thought I'd for sure lost at least one finger or more. After wrapping my hand in a towel and the bleeding subsided, I saw I would need stitches on at least one finger. The other 3 were damaged but did not need stitches. To this day, I wonder what happened. The only thing I can think of is my workpiece was "tapered" causing the pressure against the blade which after passing (or trying to) snapped the mag switches. Now, let me be clear, those mag switches are strong and I would never have thought they could be broken, least of all be the table saw. That just shows how much force a tablesaw generates. Also, standing on the "left" side does NOT insure you won't be hit by kickback.

One other thought. When I went to the "minor emergency clinic" they verified I had insurance but since it was a new provider, they did not know how much would be paid by my insurance company so they wanted me to pay the entire amount. So, I decided to go to Walgreen's and get some butterfly bandages, tape and betadine and doctor myself. Now, imagine me standing in line with my bloody towel and blood still coming out. Needless to say, they let me move to the front of the line!

Jerry

Greetings fellow wood workers. The picture No 5 Reminded me of an incident when I was working at The Royal Melbourne Institute of Technology Wood Pattern Making Department. I was working as a Pattern Maker Store man and was helping the Boss make some Bull Nose veranda rafters. We were trimming a bit off the end of one. I was holding the long end and he was guiding it past the blade. There was a loud bang and the loose bit came out from between the blade and the fence and hit him on the left thumb. A matter of minutes and the thumb was huge and unusable. All because he was in a hurry. He I might add had been in pattern making all his life and was approaching retirement. It makes you stop and think. Take it easy chaps.

Thats a good one.

I saw the 'blade guard removed for clarity', and don't know how they would show the excess blade height as part of the kickback issue with the guard in place. I did waste a lot of points on the sleeves and ring looking for that last item. I didn't see the board in the picture as long enough to need outfeed support if a proper pushstick were to be in use.

You could add:

Don't where long sleeves around power tools. This guy might just have to reach past the blade and remove his workpiece before the blade comes to rest. That wedding ring could also be a problem. In the shop - not away from home.

Long sleeves and rings can also be a problem. Plus, don't ruin your suits. Saw Stops also work well with dust collection.

The dovetail quiz was a bit of fun, but frankly this one is crap.

NO BLADE GUARD leads to a whole swag of other potential problems that would be largely avoided or minimised were this device in place. Things like

• with a functioning blade guard, setting the blade as low as possible to minimise contact with your fingers is completely unnecessary.

• were the blade set as high as possible -- which should be the norm -- the blade's tragectory is more up through the board at the back and down through the board at the front -- minimising the potential for a piece to be launched in a horizotal direction

agree with the riving knife and push stick

reflecting on the recent "tablesaw liability case" what I can't fathom is if a flooring installer needs to freehand rip a board to scribe it to a wall, then why aren't they using something like a portable (8") bandsaw?

I was taught not to wear jewelry around machinery either. Something as simple as a wedding band could get caught on a spinning blade and create an unfortunate situation.

I have a mounted circular saw for a table saw which only means I neither have a blade guard or a riving knife and my fence is just a piece of board nailed down to a plywood table top. I bet I am sending goosebumps to all of you now. However I always try it very hard to keep my hands (especially my precious fingers) off the blade. My best safety rule for myself is just to keep the blade height as low as possible over the cutting piece because my principle is this: You won't loose a finger unless the blade goes through.

I cut my left thumb (an 8th of an inch)before accidentally because I was in front of the table saw for more than 36 hours without sleep.

My late father however has a better advise for me. He constantly reminded me that the blade can run it does not move an inch away from where it is planted. He told me that woodworkers loose a finger (or even get minor cuts) because of two things: scared that the machine will cut them or very confident nothing bad will happen.

It is good to have these safety measures to better avoid injuries, but no safety gadget can save an unfocused woodworker. The blade will stay around the shaft so just don't touch the blade!

The comment about using a push stick on something that wide is not nessary. The push stick they show is very dangerous because it captures your hand. Forget all the gadgets out there and make a push block out of a2x6, gives you good control and when it gets cut up make another one!

One item that has disturbed me the last few years is the way one of the Technology Collage is teaching students to stand on the right hand of the fence when ripping. Have seen that several times and explained to them why it is wrong.

No matter what you are doing all ways keep in mind where that blade is.

While I am at it, am sick of having the SAW STOP saw pushed on us! It is not the answer, education is!

Log in or create an account to post a comment.

Sign up Log in