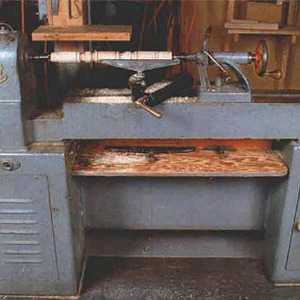

Tool Test: Heavy-Duty Benchtop Lathes

With more muscle and mass than ever, one of these midsize models could be the first and last lathe you’ll need

Synopsis: We test the new breed of midsize benchtop lathes, which have beefier castings, larger motors, and more swing over the bed than older midi-lathes. For furniture makers, these machines are more than adequate. And they supply enough torque and mass to satisfy many turners, too. Models tested include the Delta 46-460, Penn State Turncrafter Commander, General Int’l 25-200M1, General Int’l 25-114M1, and Jet JWL-1220.

Correction: PDF updated 10/2010 to fix an error in manufacturer names. Two of the lathes tested are by General Int’l not General.

Turning is a growing hobby, and newcomers need affordable lathes to get started on. So a few years back, manufacturers started stretching mini-lathes—originally designed for small projects like pens and salt shakers—in an effort to create an entry-level lathe for more ambitious turners. They added bed extensions for longer spindle work and increased the capacity over the bed for bigger bowls and platters. These souped-up minis (called “midis” by at least one manufacturer) sold by the tens of thousands, but user feedback was mixed: when furniture makers tried to turn big posts, or when turners threw a big, chunky blank onto a faceplate, these lightweight lathes didn’t have the mass or torque to handle the job. So manufacturers responded with a new breed of midsize benchtop lathes, and that’s good news for woodworkers of all stripes.

These new models offer beefed-up castings, larger motors, and even more swing over the bed than the old midis. What’s more, at $500 to $1,000 including a bed extension, their prices have not increased as much as their versatility has.

For furniture makers, whose needs range from bed posts to drawer pulls, one of these lathes will be a friend for life. Better yet for people like me, who enjoy turning for turn ing’s sake, they have the low-end torque and vibration-dampening mass to turn oddshaped burls and heavy logs into beautiful bowls, platters, and hollow vessels. And most come with the variable speed, reverse rotation, and precise indexing found on lathes that cost twice as much.

I couldn’t wait to compare these new models head to head. I limited my test to benchtop lathes with bed extensions, at least 12 in. of swing over the bed, and motors of 3⁄4 hp or more. Each lathe has a 1-in. by 8-tpi spindle and a No. 2 Morse taper headstock and tailstock. Also, each comes standard with a drive center, live tail center, knockout bar, and faceplate. You might need to buy an additional tail center, as the standard ones are a bit large for thin spindles, such as the end of a table leg.

From Fine Woodworking #215

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Rikon 10-3061 10-in. Deluxe Bandsaw

The saw has two speeds: 3,280 sfpm (surface feet per minute) for wood and 1,515 sfpm for soft metals and some plastics.

Starrett 12-in. combination square

Log in or create an account to post a comment.

Sign up Log in