If there’s one thing woodworkers create a lot of, it’s scraps and cut-offs. Here at the offices of Fine Woodworking, our cut-off bin is often overflowing with every manner of wood. Cocobolo, cherry, quartersawn oak, walnut, beech: you name it, we’ve got it. For that reason, a lot of us enjoy turning those castaway cut-offs into beautiful boxes. And there is perhaps no FW contributing author with as wide a variety of boxes under his belt as Doug Stowe.

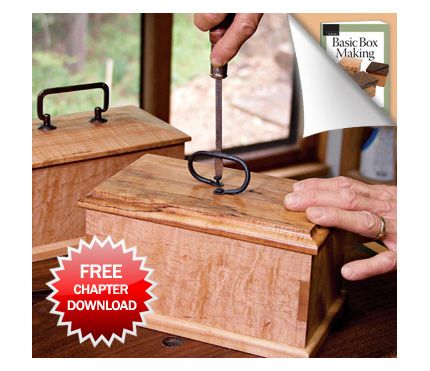

In this free chapter download from his book, Basic Box Making, Stowe shows you how to build a beautiful lap-cornered box of both quilted and spalted maple. You’ll learn techniques for grain-matching, creative inlays, and lap-corner joinery that doubles as a great exercise to keep your handtool skills honed. Enjoy!

Click here to download your free chapter!

More on Box-Making

- Box-Making Video Workshop

- Free Plan: Lift-Lid Box

- Wooden Box-Making: Design Ideas

- Elegant Veneered Boxes

Comments

Question, for the lap cornered box featured in the free chapter, might there be problems with wood movement for the glued on base?

gjwhite58 - it's a tiny effin box, dude!

LIKE HIS OTHER BOOKS I HAVE READ IT FROM COVER TO COVER AND ENJOYED IT ALL. THANKS DOUG FOR GIVING ME EVEN MORE IDEAS

Good question gjwhite58. I've fired off an email to Doug posing your question.

Hope to hear back soon.

Cheers,

-Ed Pirnik

Web Producer

FineWoodworking.com

I guess you can say that size really does matter and expansion and contraction are proportionately smaller concern on small boxes. But yes, there can be wood movement problems with a glued on base. The great thing is that if the box were subjected to extremes resulting in a loose bottom from significant expansion and contraction it would be much easier to fix than it was to make in the first place. I would consider this box to be at the upper limit of size in which this technique might be suitable. I have other simple techniques illustrated in the book that could be used on this box if a person was particularly concerned about shrinkage and expansion. My own shop and wood storage conditions are on the slightly damp side of the scale, so I tend to build tight with the expectation that the wood might shrink slightly when subjected to extremes of heating and air conditioning. Build too tight, and you can have the wood pushing the box apart at the joints in very wet weather. And so in answer to gjwhite58, the answer is yes, maybe and maybe not. And if there were only yes and no answers woodworking would not even be half the fun. Thanks for reading and enjoying box making.

Doug

I had never built a box previously, but on a whim I decided to follow this author's directions. I used a piece of scrap maple that I already had, and I must say that the box turned out better than I would have ever thought. That, and the fact that the box provides lots of practice in skills that that are useful to any wood worker's skill-set. All in all, a very good experience.

I downloaded this after being inspired by the new video workshop. Last Saturday I decided to 'have a go' and see how things turned out. I'm not quite finished yet but I'm thrilled with the way things are turning out and I'm already planing to build another box when this one is finished. Several members of my family are going to be getting boxes for Christmas this year.

For someone who are still new, making a box is such a project that you should try! It's is simple and easy to make where it no need you to use any power tools. I'm basically searching for any woodworking tips at http://shedplan-woodworkingguide.blogspot.com/

I need to build cases (hundreds) out of 1/4" walnut plywood. I'm lookin for ways to join the corners. 45's aren't strong enough. (Already tested) Box joints should be strong enough however the inside of the plywood shows on the outer edge of the box.

Any thoughts on a better way to join the corners of 1/4" plywood?

Log in or create an account to post a comment.

Sign up Log in