Since I am now the editor of the Q & A department at Fine Woodworking magazine, I got to thinking about how to spice up the column. One option is to include drama into the formula. Here’s one I hope you’ll enjoy.

Q: How do you bend a 6 in. thick piece of solid white oak into a radius of just 30 in. along its axis? I mean, without having it splinter into a million pieces.

A: Well, the answer is compressed wood. For those who know about how this works, it’s old hat. But the suspense of hearing the rack pulling the wood into that tight shape had me on the edge of my seat, wondering if somebody was going to have an unexpected and violent surprise. These folks have more videos up on YouTube; in one of them, you can see thinner pieces of compressed wood being tied into knots. Literally!

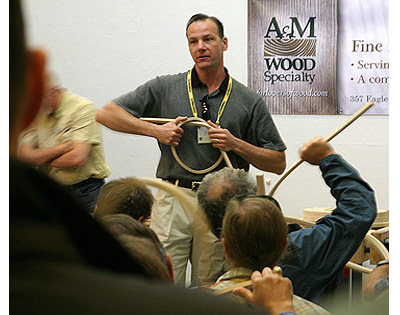

We’ve actually covered Chris Mroz’s wood-bending techniques before, but this video was new to us. Read all about how he creates spaghetti out of hardwood!

Comments

I didnt know it. Impressive

Impressive. One assumes this was green wood? Or steamed all to heck and back?

Here is a link with more information on compressed wood.

In short, it's been specially treated to make it that flexible. No chemicals or anything, though.

http://www.inventables.com/technologies/bendable-wood--2

Oh, and once it's bent, don't get it wet!

@lwj2, actually, it is wood that has been compressed using a special technology. The wood is wet when compressed, and bendable after the compression process. It gets "Saran wrapped" after compression to retain the moisture, and then you unseal it to bend. It sets into shape as it dries. Chris Mroz uses a machine made in Denmark to compress his wood. See viking099's post below for more information on compressed wood. That's exactly right--no chemicals, but try not to get it wet, as that will make the wood try to regain its unbent shape. However, you can use finishes, PVA glues (Titebond 2 apparently being most recommended), thicker viscosity CAs, and avoid PU glues (e.g. Gorilla).

@Wolodymyr: Thanks, that makes a lot of sense.

Do you, or anyone here, have any idea what the compression does to structural strength?

@viking099: Thanks for the link.

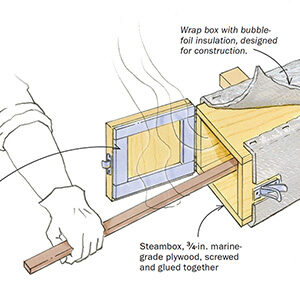

lwj2: The stock starts out as fresh sawn green, but green wood is actually too wet to bend. Even steamed wood needs to compress on the inside of the curve to bend, and water isn't compressible. We half dry the wood, and then it can be autoclaved and compressed. Structural strength is reduced a bit, tests show about 10% reduction, but steamed wood reduces in strength too. Sometimes steamed wood is going to be a lot weaker than compressed wood if you consider that to get steamed wood to bend as far as compressed wood, it is going to fracture well before it gets there. Not very strong for steam then compared with compressed. But its best to consider that compressed wood can be made into things that couldn't otherwise be made in wood. Think of bent metal designs as an example, because compressed wood will make all those kinds of scrolls and spirals. Another thought on compressed wood strength is that as it is bent, it's using up the stretch engineered into it, which actually makes it stronger again and stabilizes it.

viking: getting it wet isn't an issue with parts that were bent, kiln dried, built into an assembly (like a chair) and finished. It's not going to move wet or dry at that point. A piece that wasn't fully dried can be re-hydrated somewhat to regain flexibility. This feature is used by wood turners who can partially dry the compressed wood to make it stiffer, turn it, then re-wet it to get some flexibility back. So water can be used to enhance the workability of compressed wood at certain times in working with it, but in most cases wont affect your finished projects.

Looking for the snowshoe bending link, but no longer available. For how we bend items in the bush up in Alaska-see the video Alaska Dispatch posted on You Tube or our blog photos at http://www.Albertsnowshoes.blogspot.com. You have a quality magazine-We always enjoyed Threads too.

Looked for the snowshoe bending link,no longer available. For how we bend items in the bush up in Alaska-see video Alaska Dispatch posted on You Tube or our blog photos at http://www.Albertsnowshoes.blogspot.com. You have a quality magazine-We always enjoyed Threads too.

Looked for snowshoe bend link,not available.How we bend items in the bush up in Alaska-see Alaska Dispatch on You Tube or our blog photos at http://www.Albertsnowshoes.blogspot.com. You have a quality magazine-We always enjoyed Threads too.

Looked for snowshoe bend link,not available.How we bend items in the bush up in Alaska-see Alaska Dispatch on You Tube or our blog photos at http://www.Albertsnowshoes.blogspot.com. You have a quality magazine-We always enjoyed Threads too.

Thanks, Chris, for the clarifications & input! Always good to hear from guy in charge. A question from me: does the autoclaving--similar I suppose to autoclaving for medial applications?--break down the cellular wall structure? And is this why it's hard to plane compressed wood?

Log in or create an account to post a comment.

Sign up Log in